A kind of building steel formwork for supporting wall pouring

A technology of steel formwork and construction steel, which is used in construction, building structure, formwork/formwork components, etc., can solve the problems of high transportation cost, heavy formwork weight, inconvenient processing, etc., to avoid water leakage and air leakage, facilitate transportation and The effect of moving and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

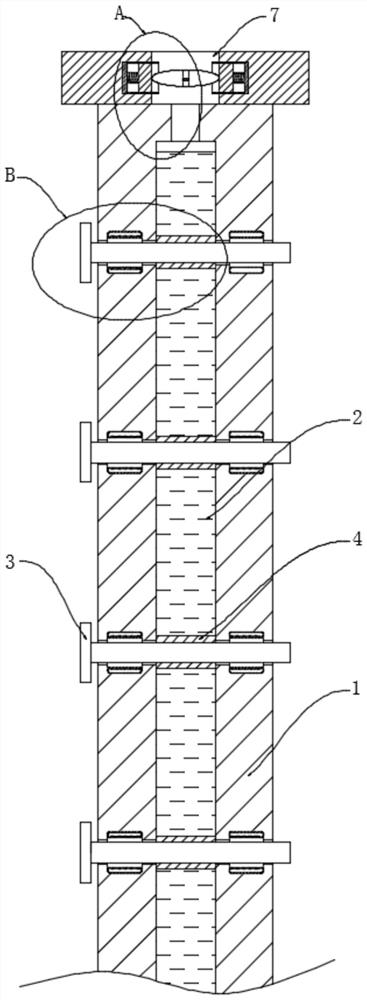

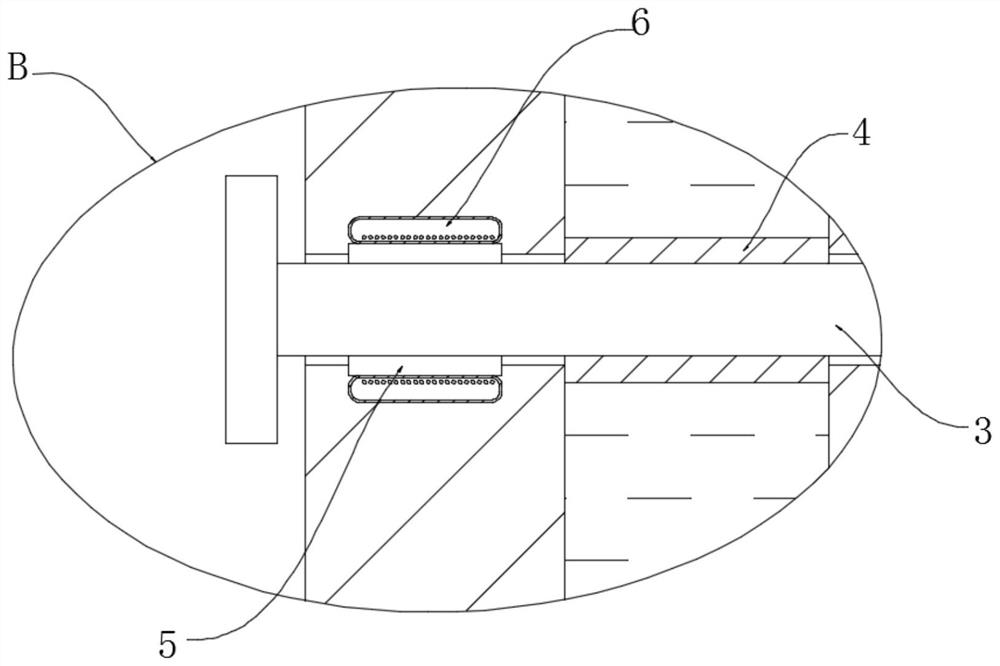

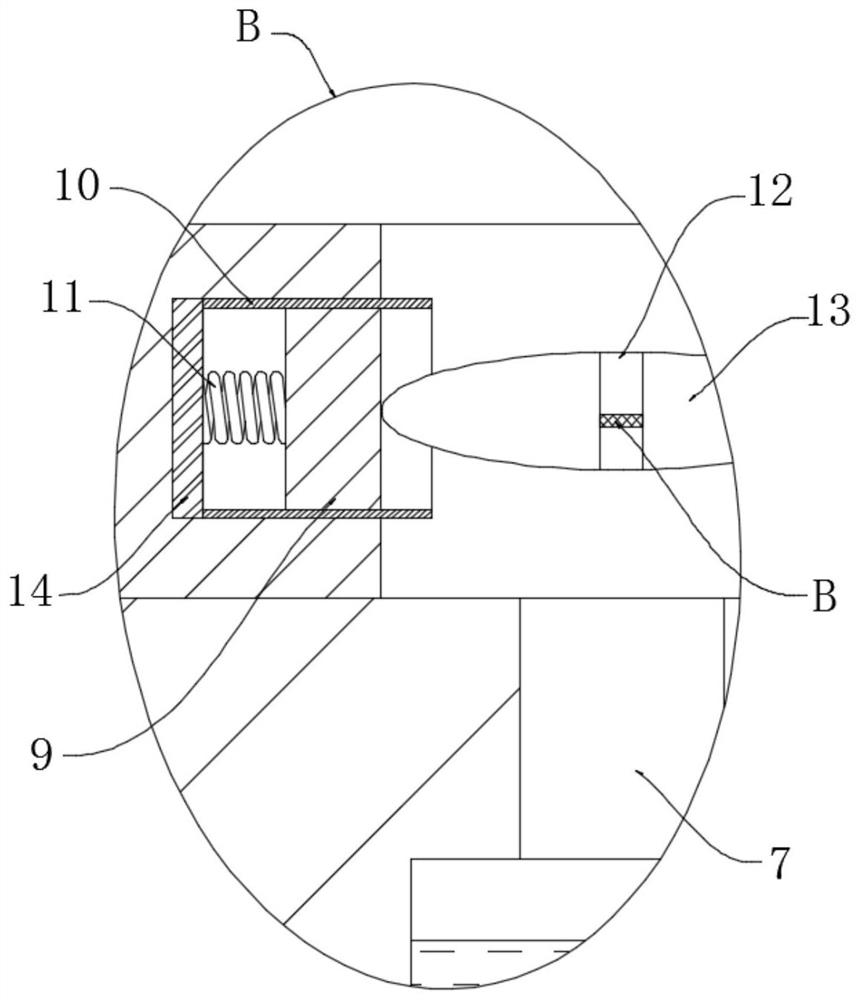

[0021] Example: refer to Figure 1-3 , a building steel formwork for supporting wall pouring, comprising a steel formwork body 1, a cavity 2 is opened inside the steel formwork body 1, and a plurality of connection holes are opened through the steel formwork body 1, and each connection hole is A positioning bolt 3 is connected, the part of the positioning bolt 3 in the cavity 2 is covered with a sealing cylinder 4 and both ends of the sealing cylinder 4 are fixedly connected with the inner wall of the cavity 2, and the positioning bolt 3 is located on the inner wall of the steel formwork body 1 in the cavity Two sides of 2 are respectively connected with a sealing ring 5, and a clamping ring 6 is sleeved on the outer side of the sealing ring 5;

[0022] The clamping ring 6 adopts an annular capsule structure and the inner wall of the clamping ring 6 is provided with a cavity. The cavity of the clamping ring 6 is equipped with a plurality of small magnetic blocks in the form of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com