Controllable air static pressure radial bearing system

A technology of radial bearing and air static pressure, applied in the direction of bearing, shaft and bearing, mechanical equipment, etc., can solve the problem of incompleteness and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

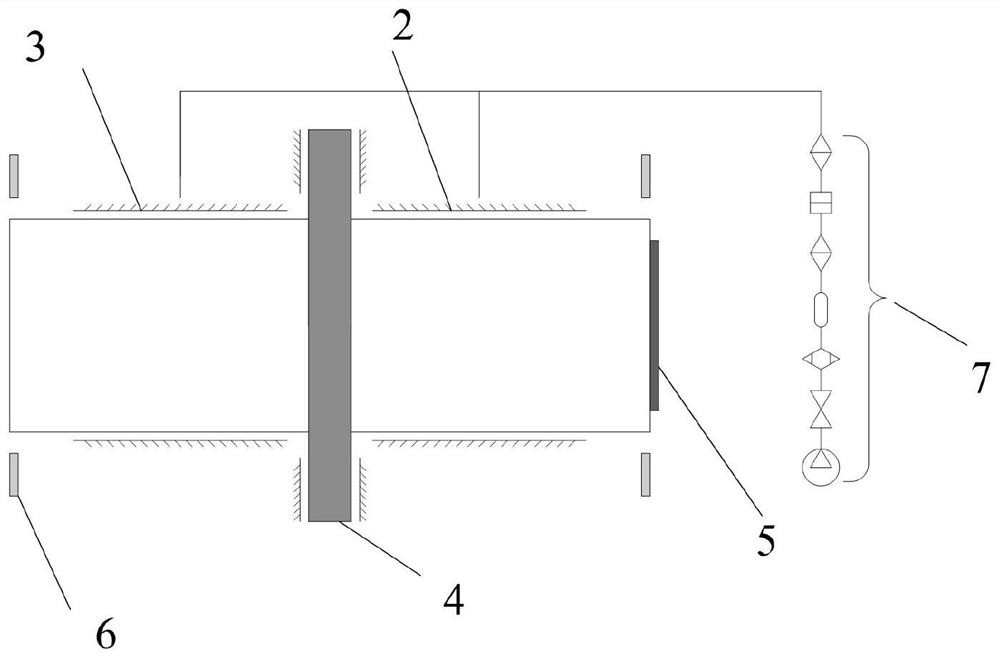

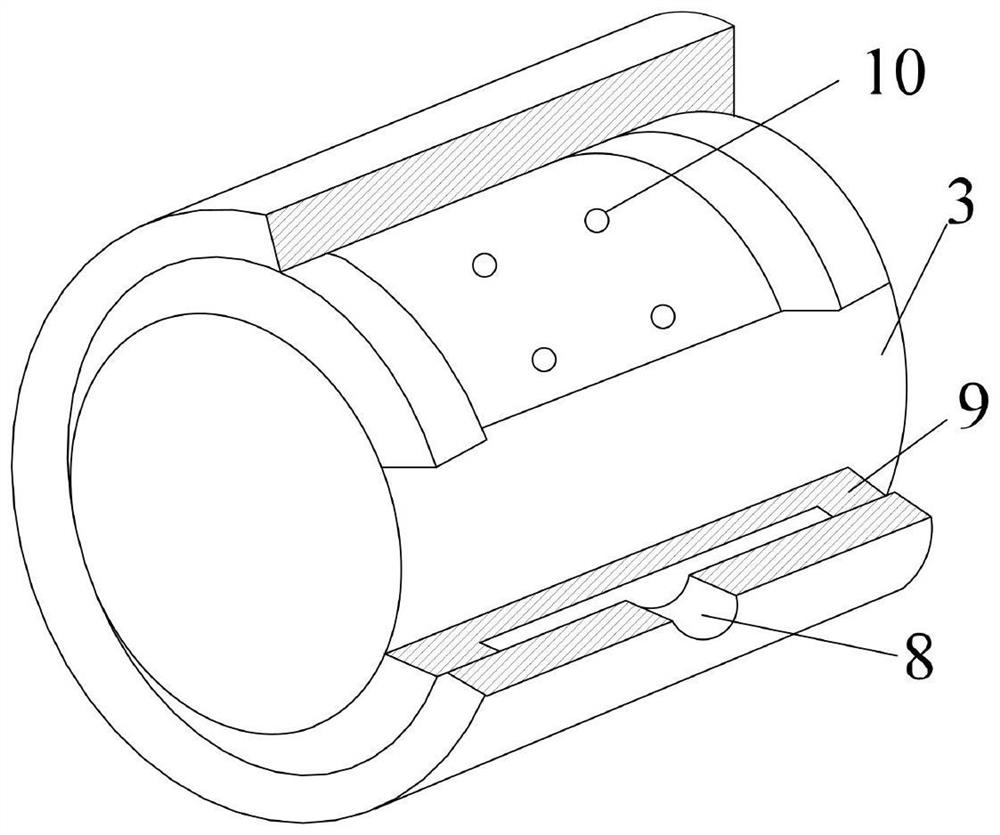

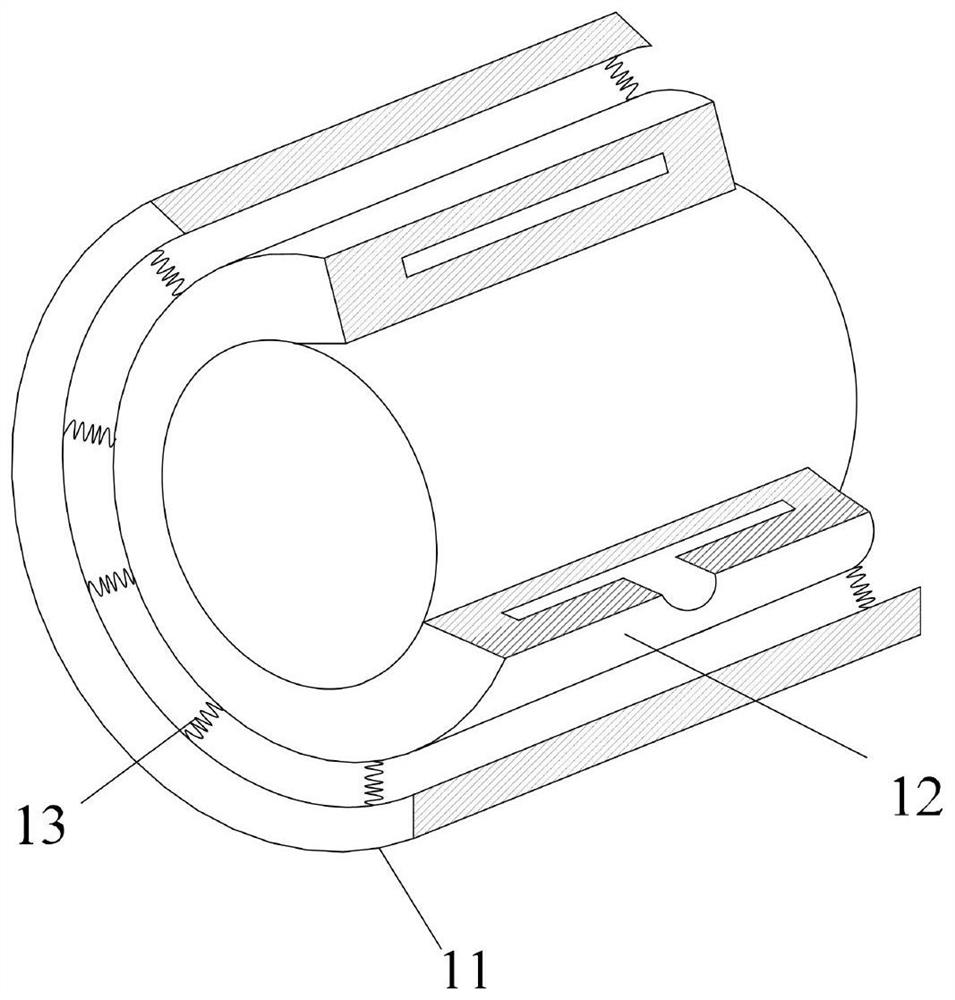

[0018] The technical solution of the present invention will be described below in conjunction with the accompanying drawings.

[0019] The front end of the aerostatic spindle rotor is connected with a new type of controllable aerostatic radial bearing through the bolt connection with the shell (the bearing bush is connected to the bearing shell through elastic support, and the piezoelectric ceramic is fixed to the bearing shell through a special clamp, and the other end acts The middle part is installed with a thrust bearing through the bolt connection with the casing, the rear end is installed with a traditional aerostatic radial bearing through the bolt connection with the casing, the drive motor is installed at the tail of the rotor, and the eddy current sensor is used together. Four pairs are vertically arranged at both ends of the main shaft, and the upper computer is connected with the eddy current sensor, and while collecting displacement signals, it applies control sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com