Device for preventing ash deposition at bypass flue inlet horizontal section of coal-fired boiler economizer

A bypass flue, coal-fired boiler technology, applied in exhaust gas devices, solid fuel combustion, combustion methods, etc., can solve the problem of affecting catalyst efficiency, flue gas temperature can not meet the requirements of denitration operation, mechanical blocking of baffle doors astringency etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

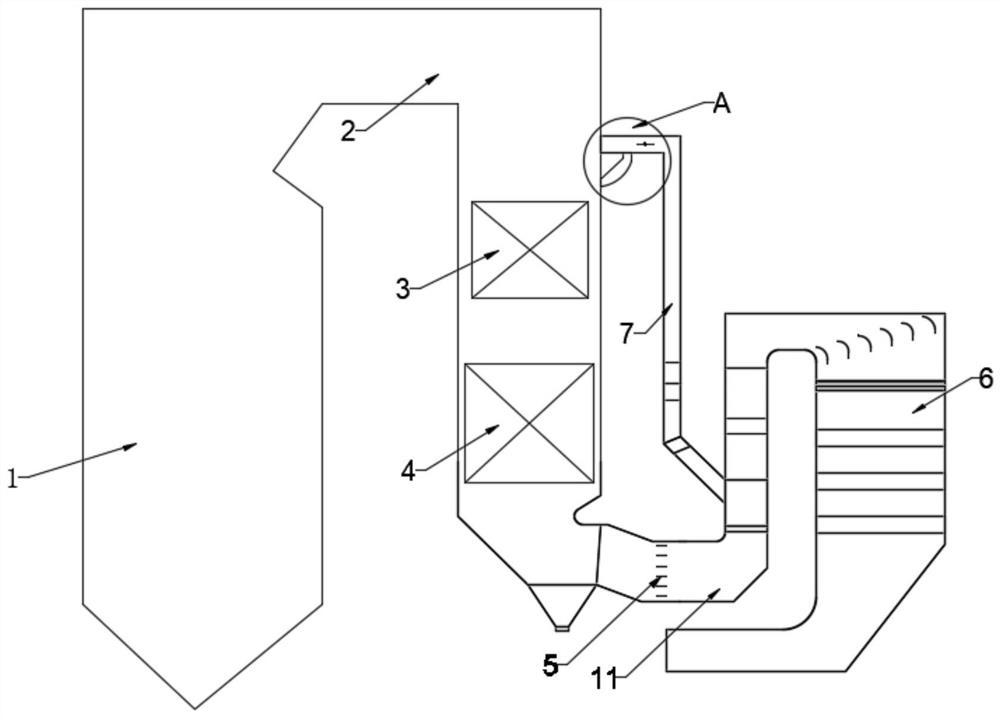

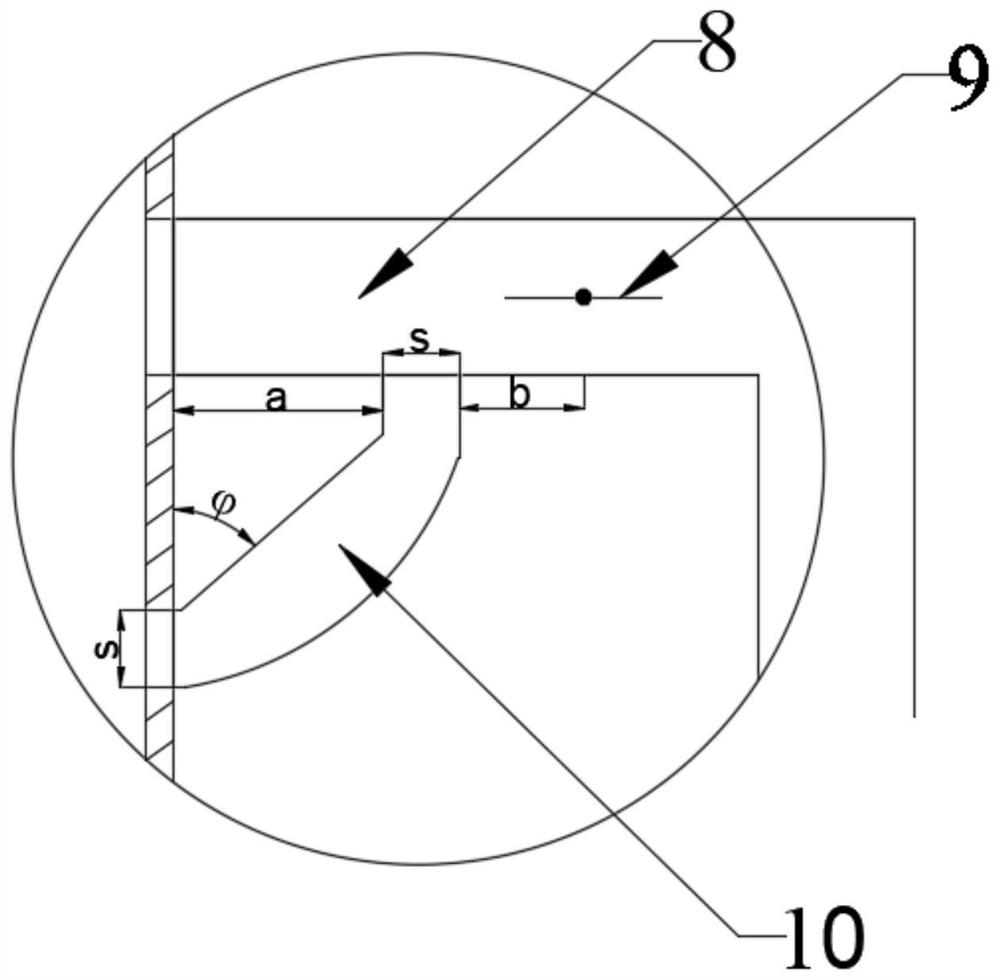

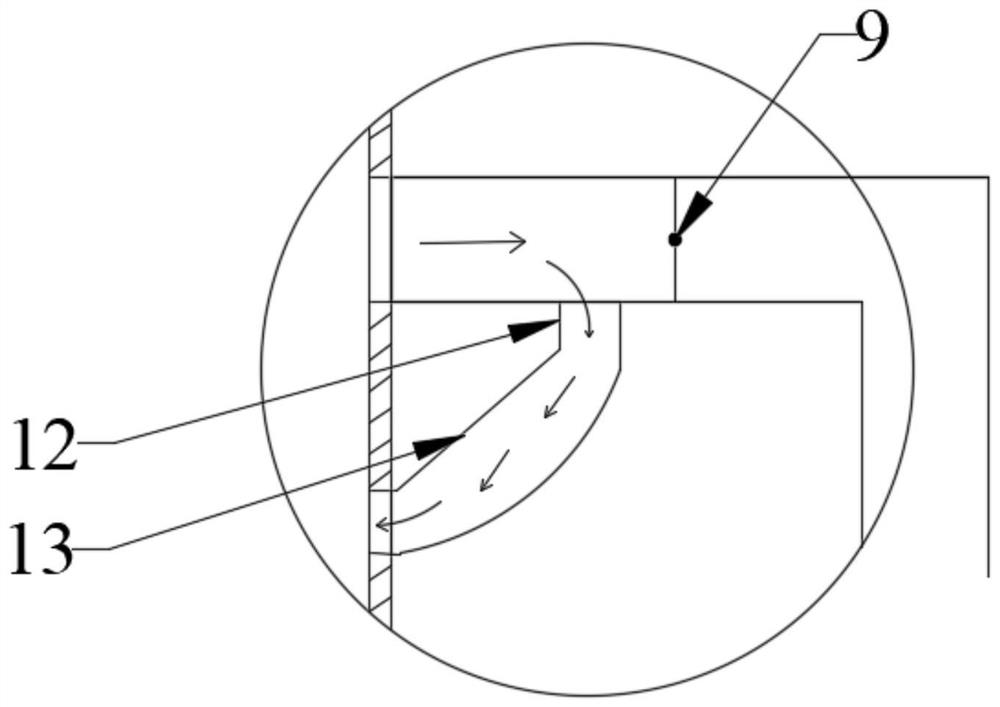

[0015] Such as Figure 1 ~ Figure 3 As shown, the present invention is a device for preventing soot accumulation at the inlet horizontal section of the bypass flue of a coal-fired boiler economizer, which includes a boiler furnace 1, and the boiler furnace 1 is connected to a low-temperature superheater 3, Boiler economizer 4, SCR denitrification reactor 6, a boiler bypass flue 7 is set between the outlet of the boiler furnace outlet flue 2 and the entrance of the SCR denitrification reactor 6, and a boiler bypass flue 7 is installed at the entrance of the boiler bypass flue 7 The bypass flue baffle door 9, the main baffle door 5 is installed on the connecting flue 11 between the boiler economizer 4 and the SCR denitrification reactor 6, and the bypass flue baffle door 9 is set on the boiler bypass flue On the horizontal flue 8 of the bypass flue inlet of Road 7, there is a connected bypass between the horizontal flue 8 of the bypass flue inlet before the bypass flue baffle do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com