Graded micro-mist filler humidifier

A humidifier and micro-mist technology, applied in air humidification systems, direct contact heat exchangers, heating methods, etc., can solve the problems of small flow resistance and limited humidification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

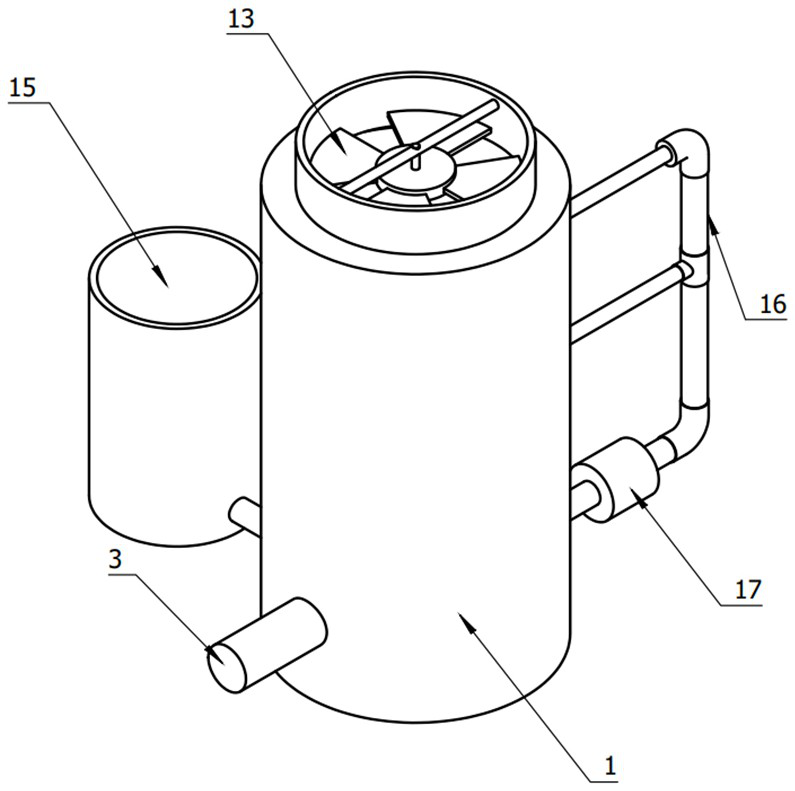

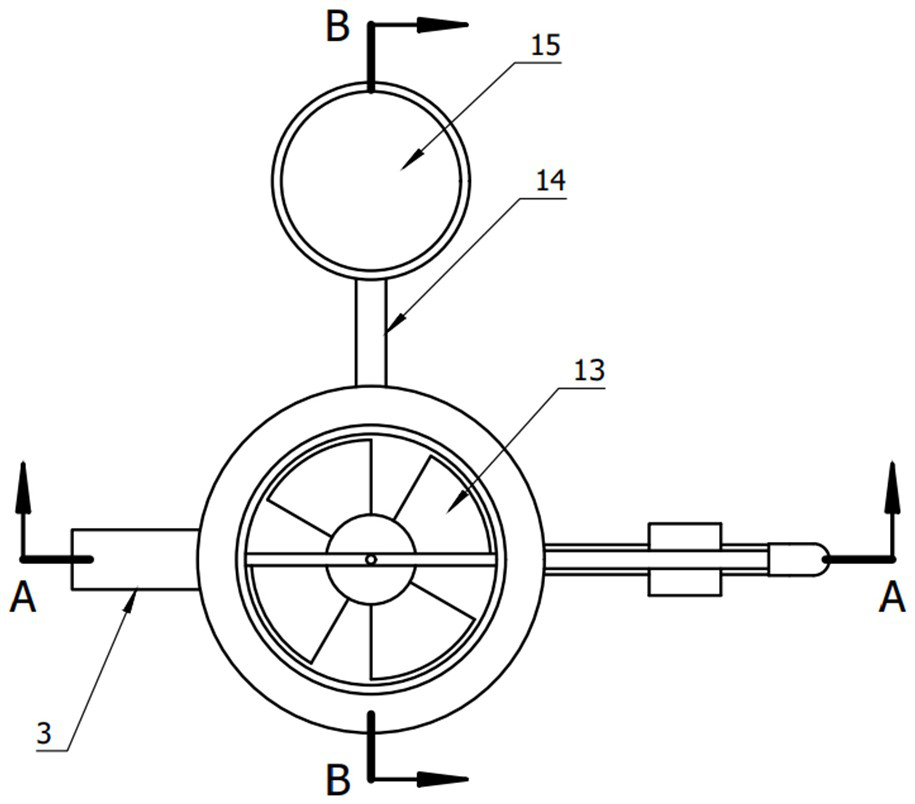

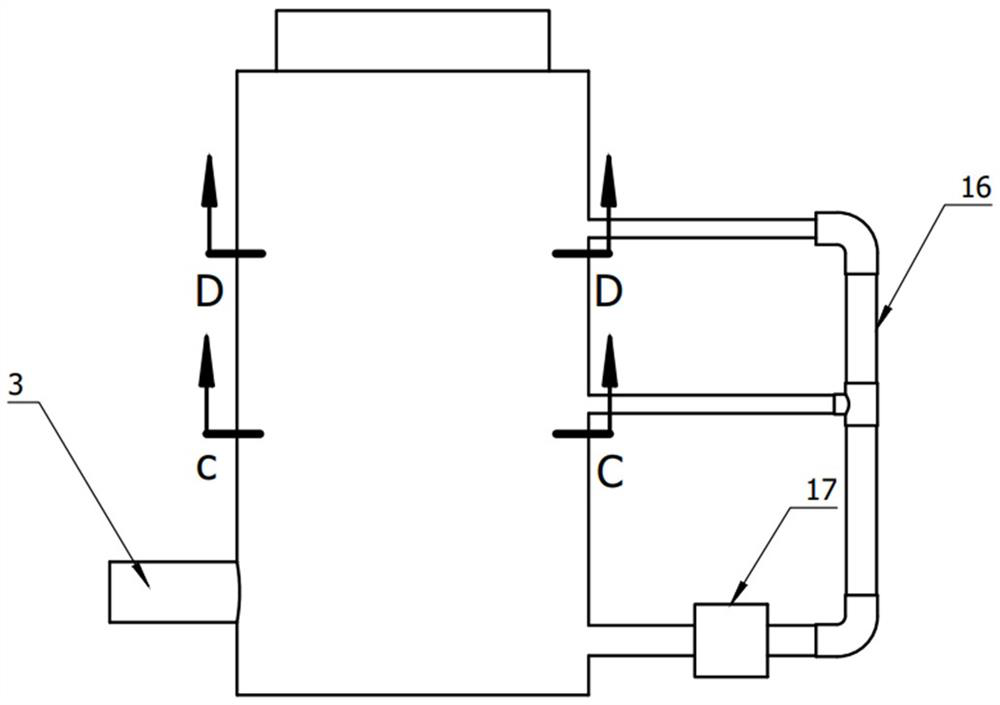

[0030] see figure 1 , a hierarchical micro-mist filler humidifier includes a barrel-shaped main body 1; see Figure 4 , The main body 1 is divided into water collection chamber 2, micro-mist humidification area 18, filler humidification area 19, gas-liquid rectification area 20 and exhaust chamber 12 from bottom to top.

[0031] see Figure 4 and figure 2 , the main body 1 wall on one side of the water collection chamber 2 is connected to the air inlet pipe 3; see Figure 5 , the wall of the main body 1 on the other side of the water collection chamber 2 is connected to the external water tank 15 through the water pipe 14; see figure 1 and Figure 4 , the wall of the main body 1 on the third side of the water collection chamber 2 is connected to the water inlet of the circulating water pump 17 through a pipeline, and the water outlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com