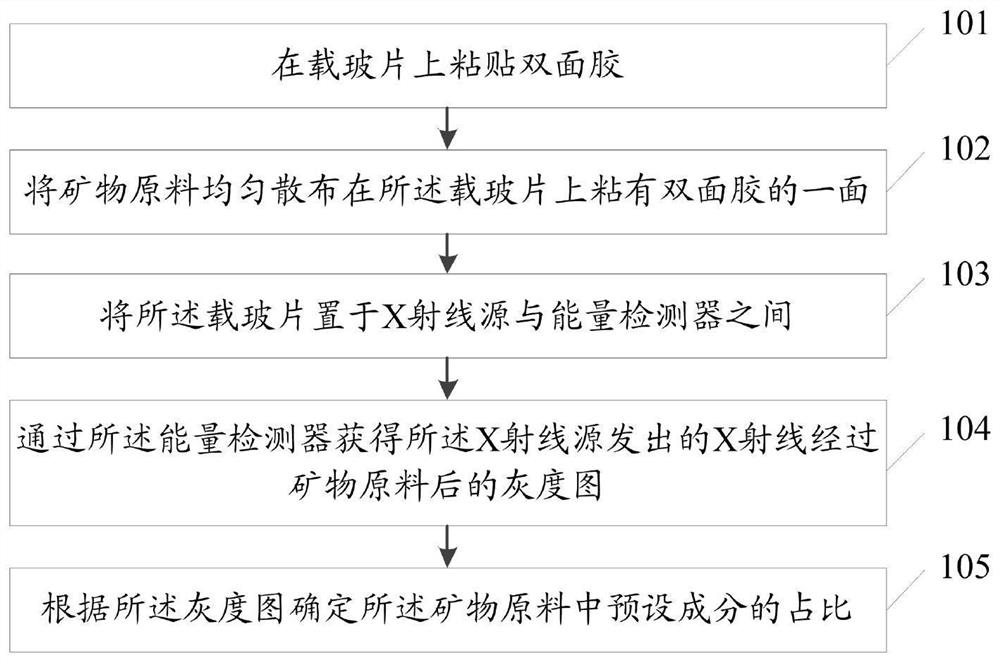

Mineral purity detection method

A purity detection and mineral technology, applied in the field of mineral purity detection, can solve the problems of long detection cycle, lengthy chemical pretreatment process, high standard substance requirements, etc., and achieve the effect of improving detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Step 1. Evenly spread the quartz sand particles (mineral raw material particles 2) with a particle size of 20 to 30 meshes on the glass slide 3 with double-sided adhesive, and ensure that the area of the adhered mineral particles is not less than 2cm 2 .

[0065] Step 2. Shake off the unglued particles.

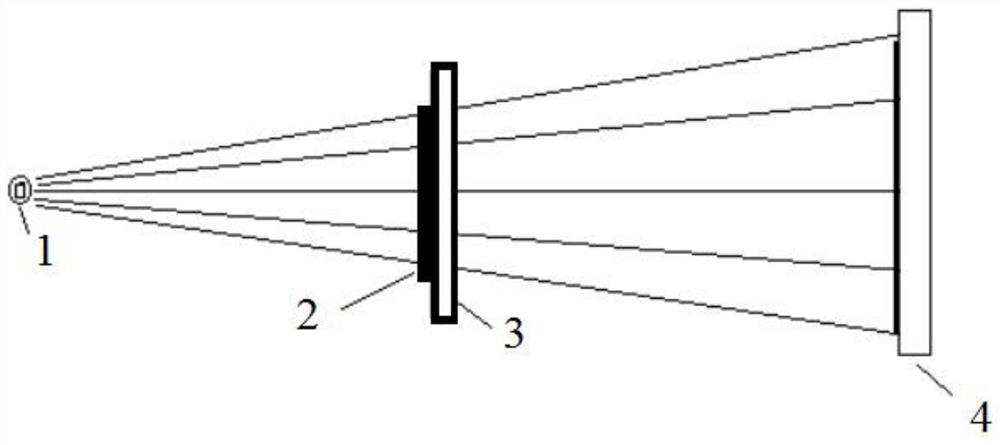

[0066] Step 3. Place the glass slide 3 with the mineral raw material particles 2 attached between the voltage-adjustable X-ray source 1 and the 16-bit A / D conversion flat panel detector, so that the main axis of the X-ray is perpendicular to the slide glass The orientation of the slice 3 plane through the mineral sample particles, such as figure 2 shown.

[0067] Step 4: Turn on the X-ray source 1, set the voltage of the X-ray source 1 to 40Kv, the current to 100μA, and the exposure time to 1s to obtain a grayscale image of the X-ray attenuated by the mineral raw material particles 2 .

[0068] Step 5. Use the image processing software to process the grayscale imag...

Embodiment 2

[0071] Step 1. Evenly spread the mineral raw material zircon sand particles with a particle size of 60-200 mesh on the glass slide 3 stuck with double-sided adhesive tape.

[0072] Step 2. Shake off the unglued particles.

[0073] Step 3, placing the glass slide 3 with the mineral raw material particles 2 attached between the voltage-adjustable X-ray source 1 and the 16-bit A / D conversion flat panel detector, so that the X-rays are perpendicular to the plane of the slide glass 3 The direction of the mineral sample particles, such as figure 2 shown.

[0074] Step 4: Turn on the X-ray source 1, set the voltage of the X-ray source 1 to 160Kv, set the current to 10μA, and set the exposure time to 5s to obtain the corresponding grayscale image after the X-rays are attenuated by the mineral raw material particles 2.

[0075] Step 5. Use the image processing software to process the grayscale image according to the following process: set a 5mm×5mm square research area, binarize the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com