High-voltage-resistant m-ABA-SiO2/alicyclic epoxy resin nano composite insulating material and preparation method thereof

A technology of m-aba-sio2 and insulating materials, which is applied in the field of insulation and high voltage resistance, can solve the problems of high surface activity and easy agglomeration, and achieve the effect of non-toxic to human body, simple processing technology and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

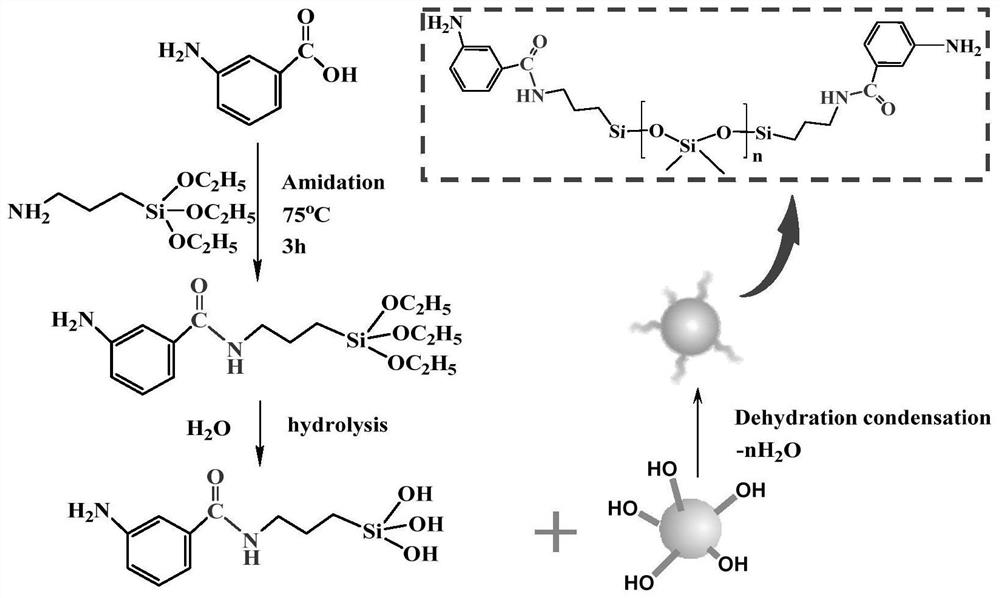

Method used

Image

Examples

Embodiment 1

[0035] 1. Determination of curing process

[0036] All glassware and magnetic stir bars were ultrasonically cleaned and rinsed with ultrapure water prior to preparation.

[0037] First, according to the nature of the curing agent, preset the ratio of the curing agent to the cycloaliphatic epoxy resin (cycloaliphatic epoxy resin: anhydride curing agent = 100:80) and the curing process (100°C / 2h+150°C / 4h). Then add liquid cycloaliphatic epoxy resin and acid anhydride curing agent into the beaker according to the preset proportioning conditions, stir well at room temperature to obtain a transparent solution; then cure the transparent solution according to the preset curing conditions.

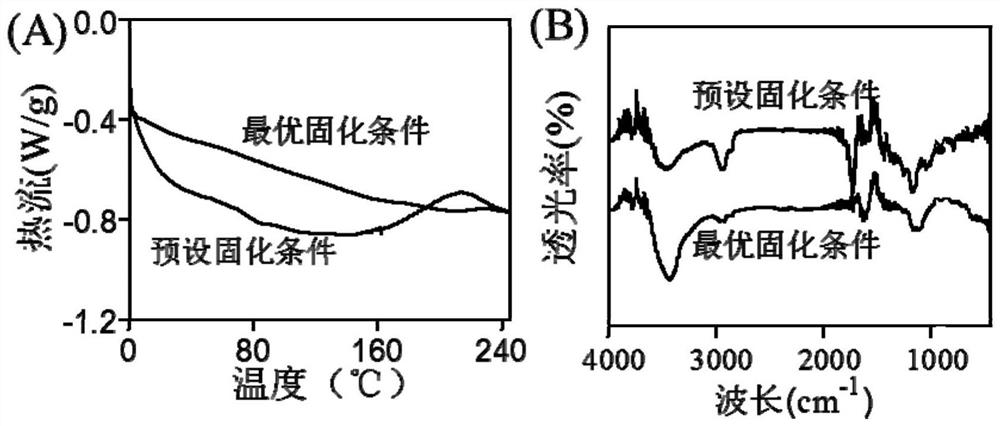

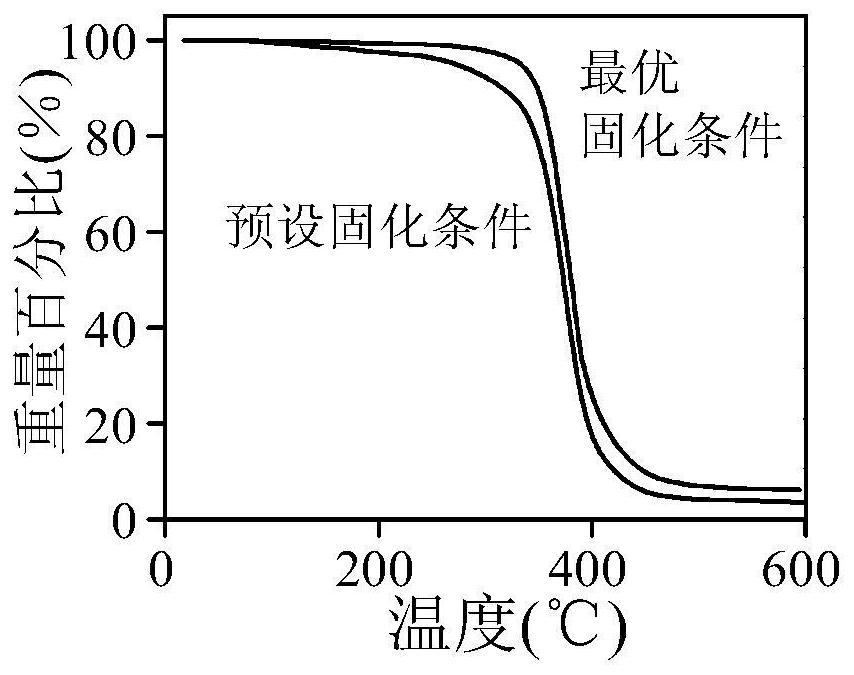

[0038] Such as figure 1 As shown, the DSC curve (A) of the cycloaliphatic epoxy resin after curing under the preset conditions has a curing exothermic peak between 150 and 250 ° C, and the infrared spectrum (B) is 910 cm -1The appearance of epoxy groups indicates that the curing reaction is no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com