Tough glaze material for ceramic tile renovation and preparation method thereof

A tough glaze and ceramic tile technology, which is applied in the field of tough glaze materials for tile renovation and its preparation, can solve the problems that coatings are not suitable for tile renovation, etc., and achieve the effects of excellent safety, cost reduction, and high coating hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

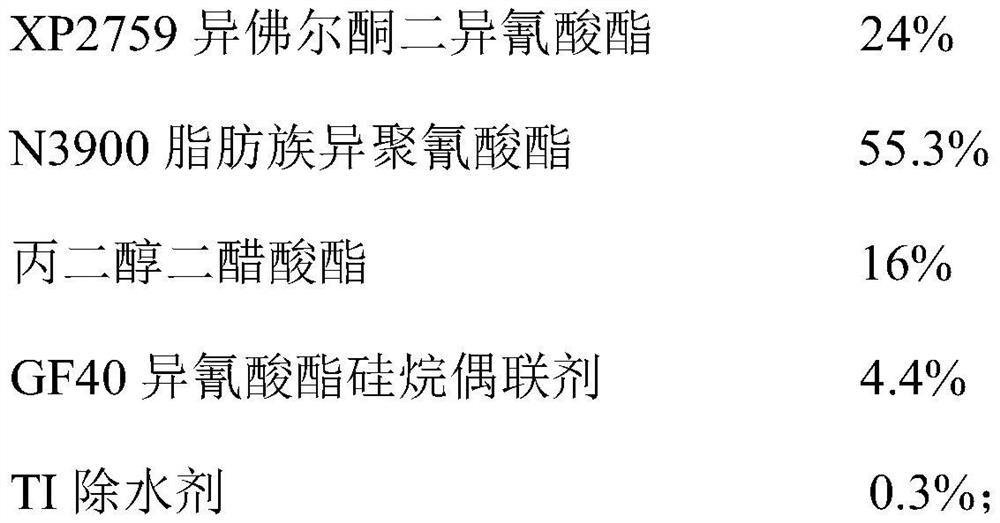

Embodiment 1

[0053] A kind of ceramic tile renovation tough glaze material of the present embodiment comprises A component and B component, wherein, by weight percentage,

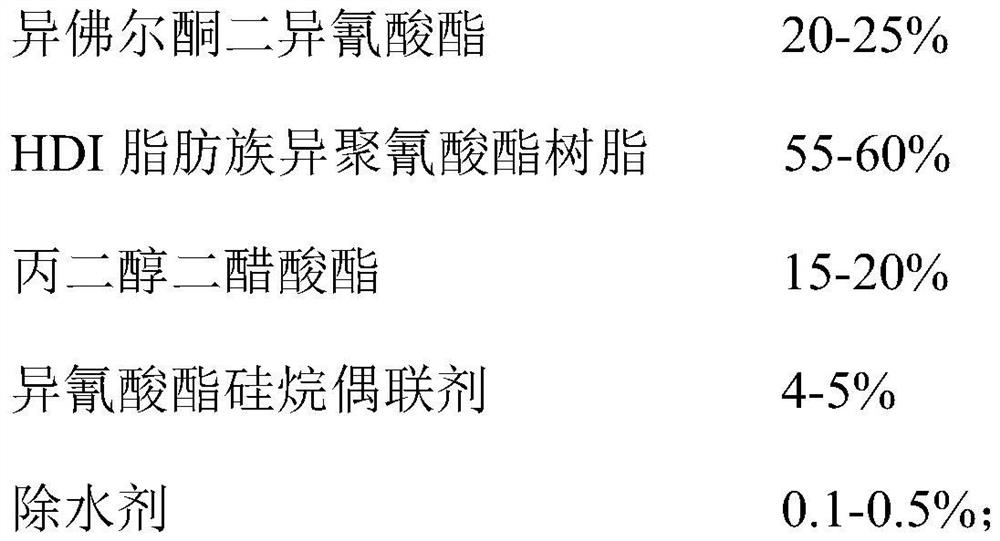

[0054] A component contains the following components:

[0055]

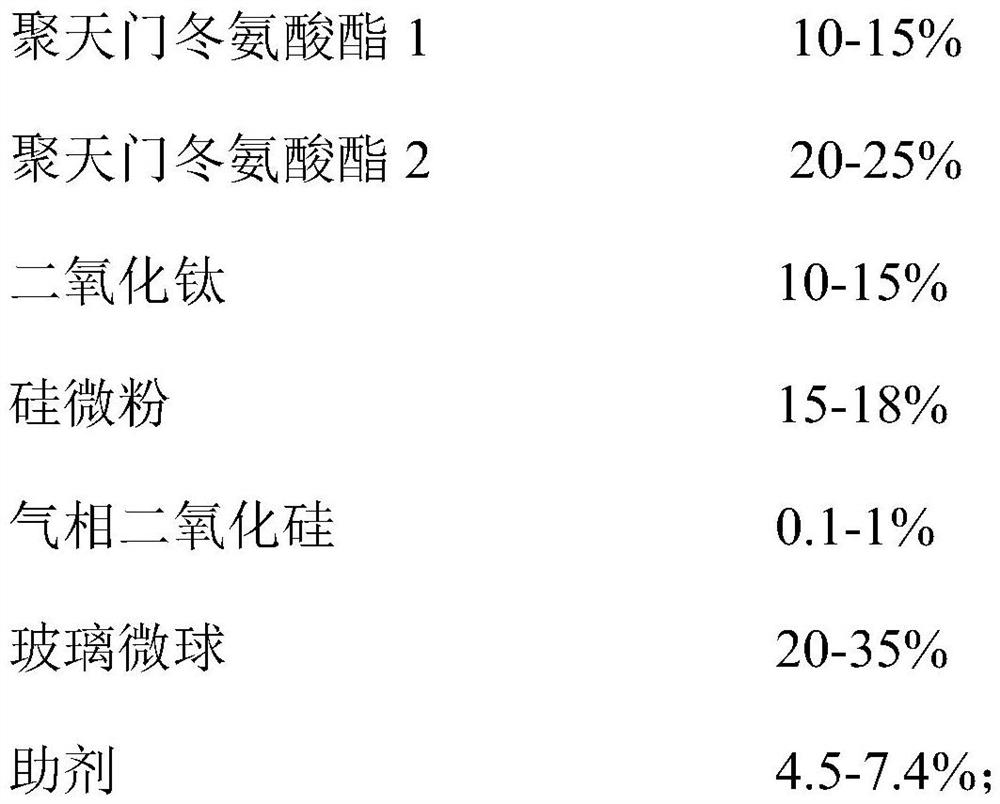

[0056] Part B contains the following components:

[0057]

[0058] The mass ratio of component A to component B is 1:2.3.

[0059] The preparation method of the tile renovation tough glaze material of the present embodiment comprises the steps:

[0060] 1) Mix isophorone diisocyanate, HDI aliphatic isocyanate resin, isocyanate silane coupling agent, propylene glycol diacetate, and water remover at 400 rpm for 30 minutes to obtain component A;

[0061] 2) Add polyaspartic acid ester 1 and polyaspartic acid ester 2 according to the proportion, raise the temperature to 60°C, stir at 500rpm for 8min; 10min; then add titanium dioxide, silicon micropowder, fumed silica, and glass microspheres in sequence according to the proportion, and disperse for 30m...

Embodiment 2

[0064] The difference between this embodiment and embodiment 1 is that the mass ratio of component A to component B is 1:2, and the others are the same as in embodiment 1.

Embodiment 3

[0066] The difference between this embodiment and embodiment 1 is that the mass ratio of component A to component B is 1:3, and the others are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com