Oil-soluble demulsifier for oil field, and preparation method thereof

An oil-soluble, demulsifier technology, applied in the field of oil-soluble demulsifiers and their preparation, can solve the problems of complex components of demulsifiers, significant non-environmental protection performance, low safety, etc., to achieve increased dissolution and dispersion performance, obvious demulsification effect, The effect of improving diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

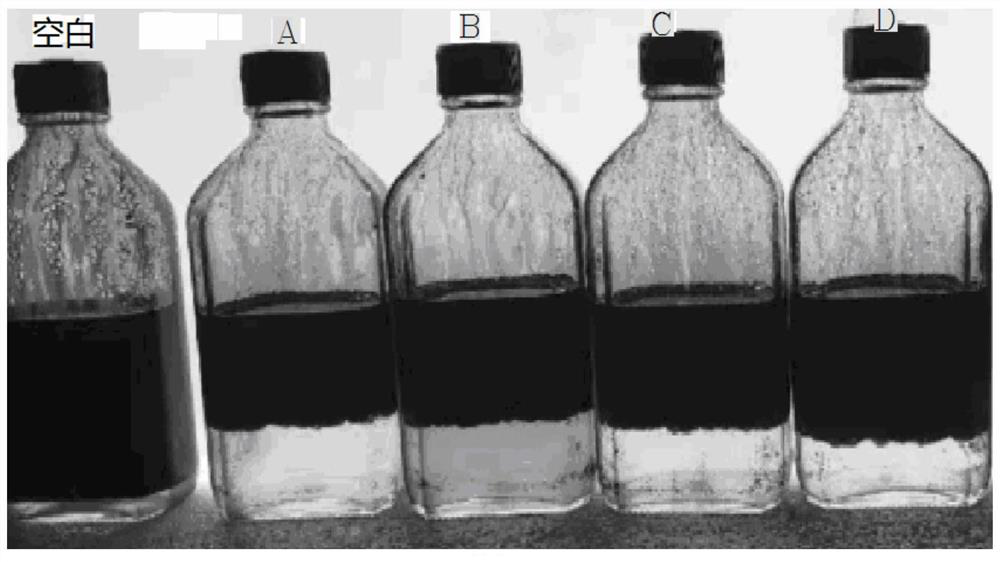

Image

Examples

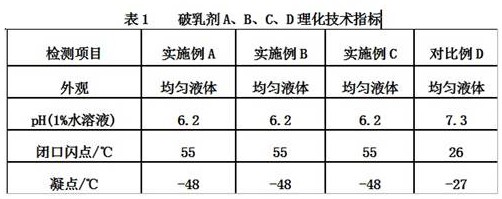

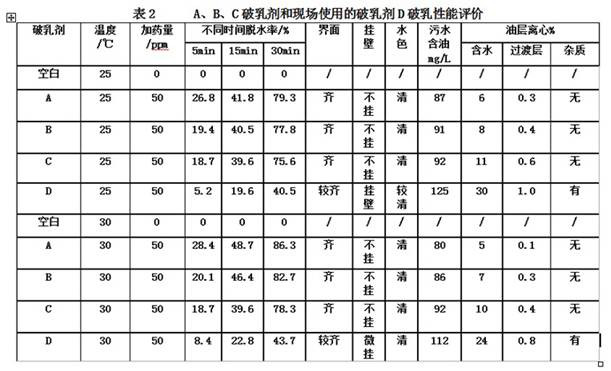

Embodiment 1

[0024] The oil-soluble demulsifier of this embodiment is composed of the following components according to the mass percentage: polyoxyethylene polyoxypropylene stearyl ether 15%, polyoxyethylene polyoxypropylene polyether 20%, PODE 3 30%, PODE 4 35%.

[0025] Preparation method: According to the proportion of the above components, the solvent PODE 3 and PODE 4 Add and blend into the blending tank, and then blend polyoxyethylene polyoxypropylene stearyl ether and polyoxyethylene polyoxypropylene polyether into the same blending tank. Mix and stir at normal temperature and pressure for 30 minutes to obtain demulsifier A.

Embodiment 2

[0027] The oil-soluble demulsifier of this embodiment is composed of the following components according to the mass percentage: polyoxyethylene polyoxypropylene stearyl ether 15%, polyoxyethylene polyoxypropylene polyether 15%, PODE 3 35%, PODE 4 35%.

[0028] The preparation method is the same as in Example 1 to obtain demulsifier B.

Embodiment 3

[0030] The oil-soluble demulsifier of this embodiment is composed of the following components according to the mass percentage: polyoxyethylene polyoxypropylene stearyl ether 15%, polyoxyethylene polyoxypropylene polyether 10%, PODE 3 40%, PODE 4 35%.

[0031] The preparation method is the same as in Example 1 to obtain demulsifier C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com