Method for regenerating spent catalyst and method and device for desulfurizing sulfur-containing hydrocarbon

A technology for catalysts to be produced and sulfur-containing hydrocarbons, which can be used in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc. Activity and strength, the effect of avoiding excessive water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0123] The method includes:

[0124] (1) introducing hydrogen and sulfur-containing hydrocarbon raw materials into a sulfur-containing hydrocarbon desulfurization unit to contact with a catalyst to perform a desulfurization reaction to obtain a raw catalyst and a desulfurization stream;

[0125] (2) regenerating the spent catalyst;

[0126] Wherein, the regeneration operation in step (2) is carried out using the method described in the aforementioned first aspect;

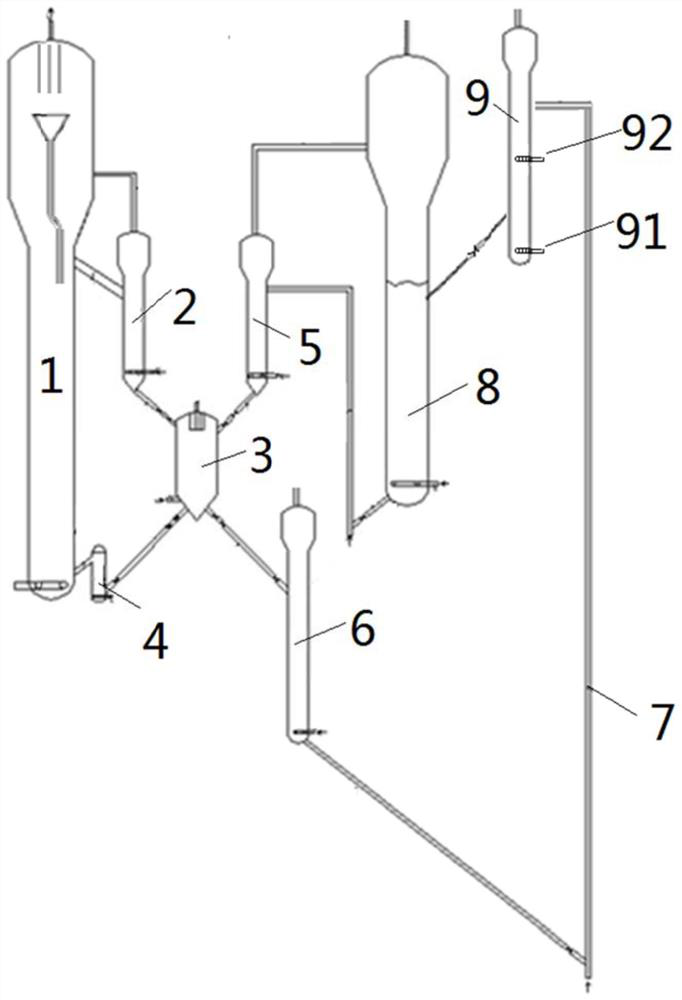

[0127] The operation of introducing hydrogen and sulfur-containing hydrocarbon feedstock into the sulfur-containing hydrocarbon desulfurization unit to contact with the catalyst includes: introducing hydrogen and sulfur-containing hydrocarbon feedstock into the desulfurization reactor 1 to contact with the catalyst for desulfurization reaction, and the obtained The spent catalyst is introduced into the regeneration unit sequentially from the reactor receiver 2, the lock hopper 3, the regenerator feed tank 6 and th...

Embodiment 1

[0153] use figure 1 The sulfur-containing hydrocarbon desulfurization unit shown performs desulfurization.

[0154] Wherein, in the sulfur-containing hydrocarbon desulfurization unit:

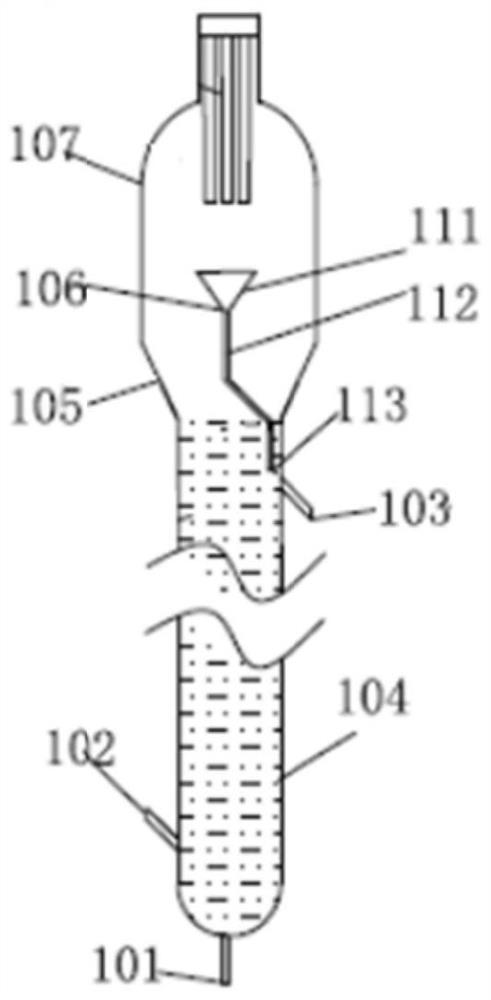

[0155] Desulfurization reactor: 3 components are set in the settling section of the reactor, the opening of the components is circular, the angle between the baffle plate of the cone part of the component and the horizontal plane is 50°, the component is provided with a 200mm high enclosure on the cone part, and the component The ratio of the upper opening of the cone part to the cross-sectional area of the reactor settling section is 0.2, and the reactor settling section is provided with a cyclone separator;

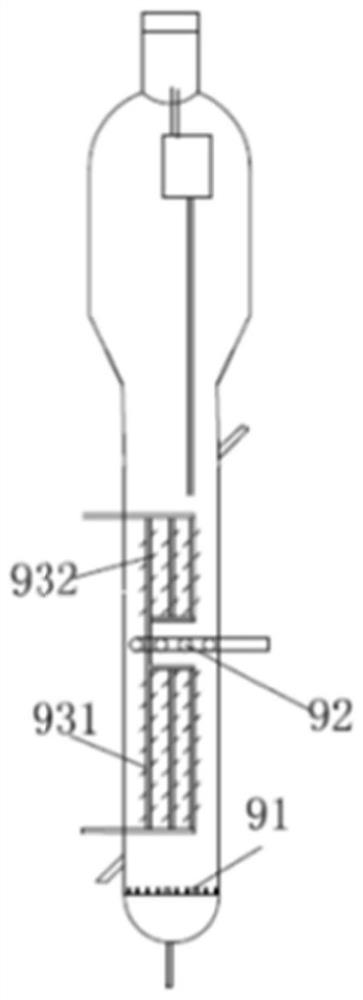

[0156] The first regenerator: There are two upper and lower gas distributors in the regeneration section. The upper gas distributor is a tubular distributor, and the branch pipe is equipped with nozzles with openings facing downwards. The angle a between the center line of the nozzle ...

Embodiment 2

[0166] Adopt the sulfur-containing hydrocarbon desulfurization device identical with embodiment 1 to carry out desulfurization, wherein, difference is:

[0167] In the sulfur-containing hydrocarbon desulfurization unit:

[0168] Desulfurization reactor: 3 components are set in the settling section of the reactor. The opening of the components is square. The angle between the baffle plate of the cone part of the component and the horizontal plane is 40°. The ratio of the upper opening of the cone part to the cross-sectional area of the settling section of the reactor is 0.1; the settling section of the reactor is provided with a cyclone separator;

[0169] The first regenerator: There are two upper and lower gas distributors in the regeneration section. The upper gas distributor is a tubular distributor, and the branch pipe is equipped with nozzles with openings facing downwards. The angle a between the center line of the nozzle and the vertical line is 10. °, the first rege...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com