High-temperature pipeline vibration reduction device with guide bracket and vibration reduction method

A technology for guiding brackets and vibration damping devices, which is applied in the directions of pipeline brackets, pipe components, pipes/pipe joints/pipe fittings, etc., can solve problems such as personnel burns, affecting the safe and stable operation of nuclear power plant units, and failing to meet emergency defect processing time requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

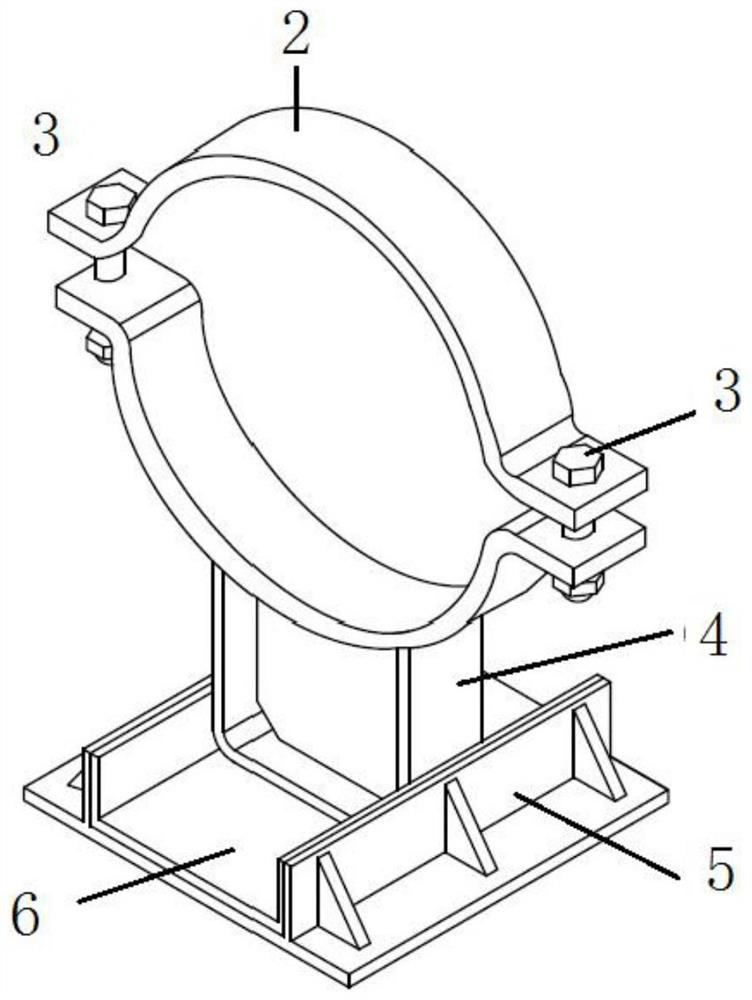

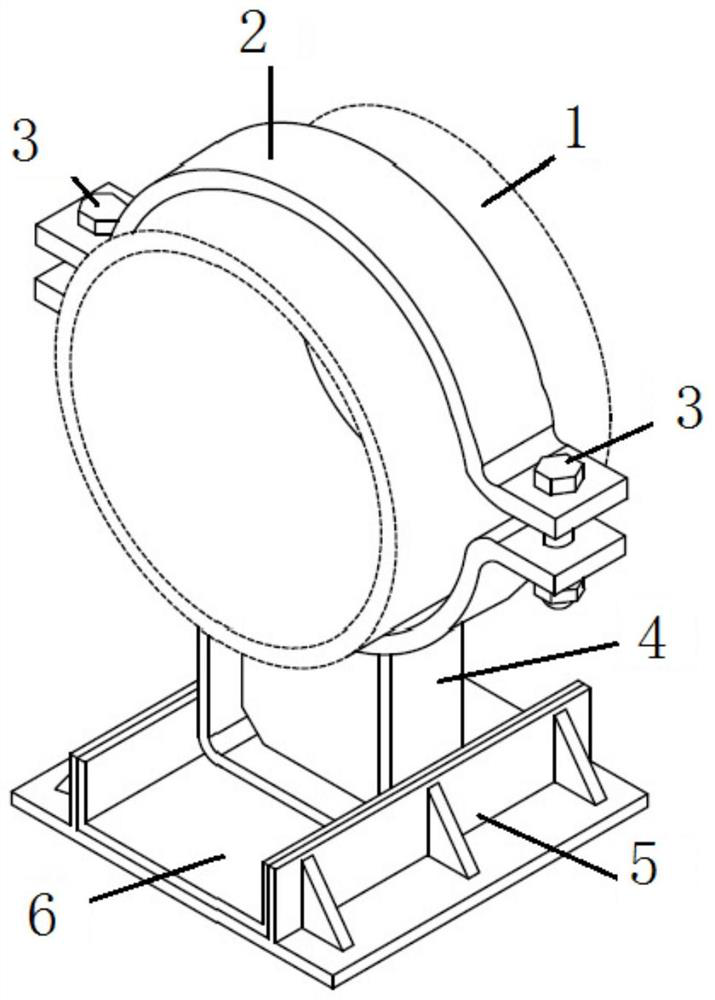

[0031] The vibration damping device and vibration damping method for a high-temperature pipeline with a guide bracket provided by the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0032] Such as figure 1 As shown, the present invention provides a high-temperature pipeline damping device with a guide bracket, including an upper pipe clip 2, a locking bolt 3, a lower pipe clip 4, a guide base 5, a polytetrafluoroethylene pad 6, and an upper pipe clip 2 The upper and lower pipe clips 4 are all semicircular structures, with protruding bolt holes respectively provided on both sides, and connected by locking bolts 3; Cooperate; the bottom of the lower pipe clamp 4 is welded with a guide track matching the guide base 5, the guide track is embedded in the guide base 5, and a polytetrafluoroethylene pad 6 is laid in the guide base 5.

[0033] This method comprises the following steps:

[0034] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com