Mop capable of squeezing water at two ends and assembly thereof

A mop and component technology, which is applied in cleaning carpets, floors, cleaning equipment, etc., can solve the problems of not easy to squeeze dry, easy to damage the foam head, and increase the burden on the user's body, so as to improve the shrinkage speed and reset speed, Enrich the use environment and enhance the effect of experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

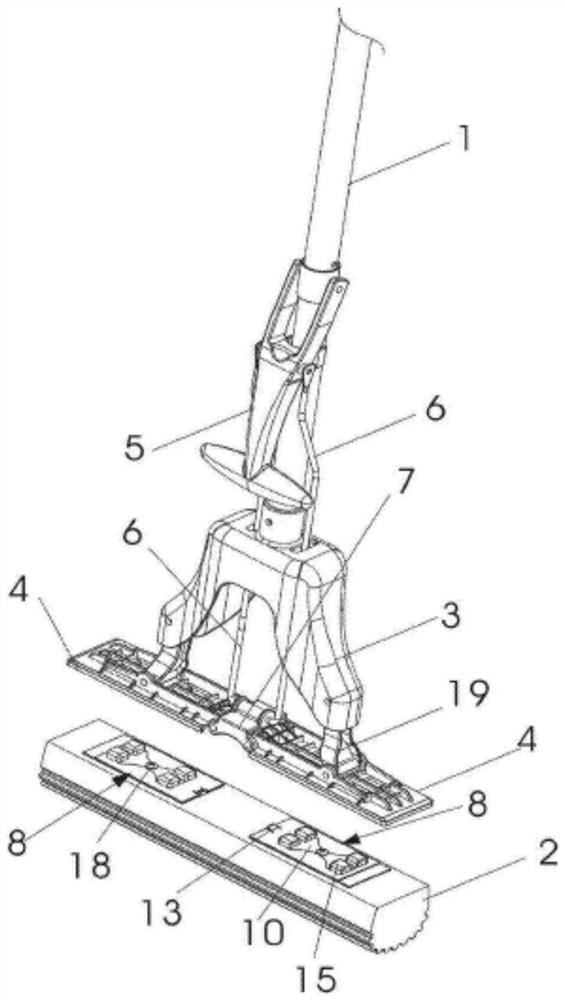

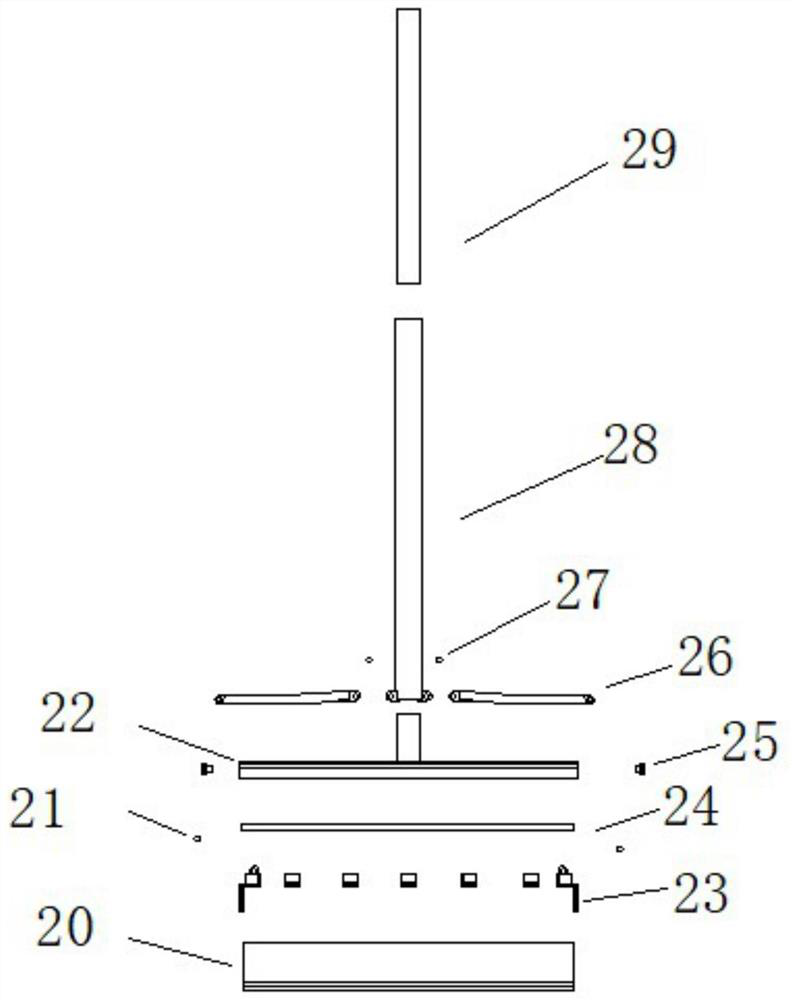

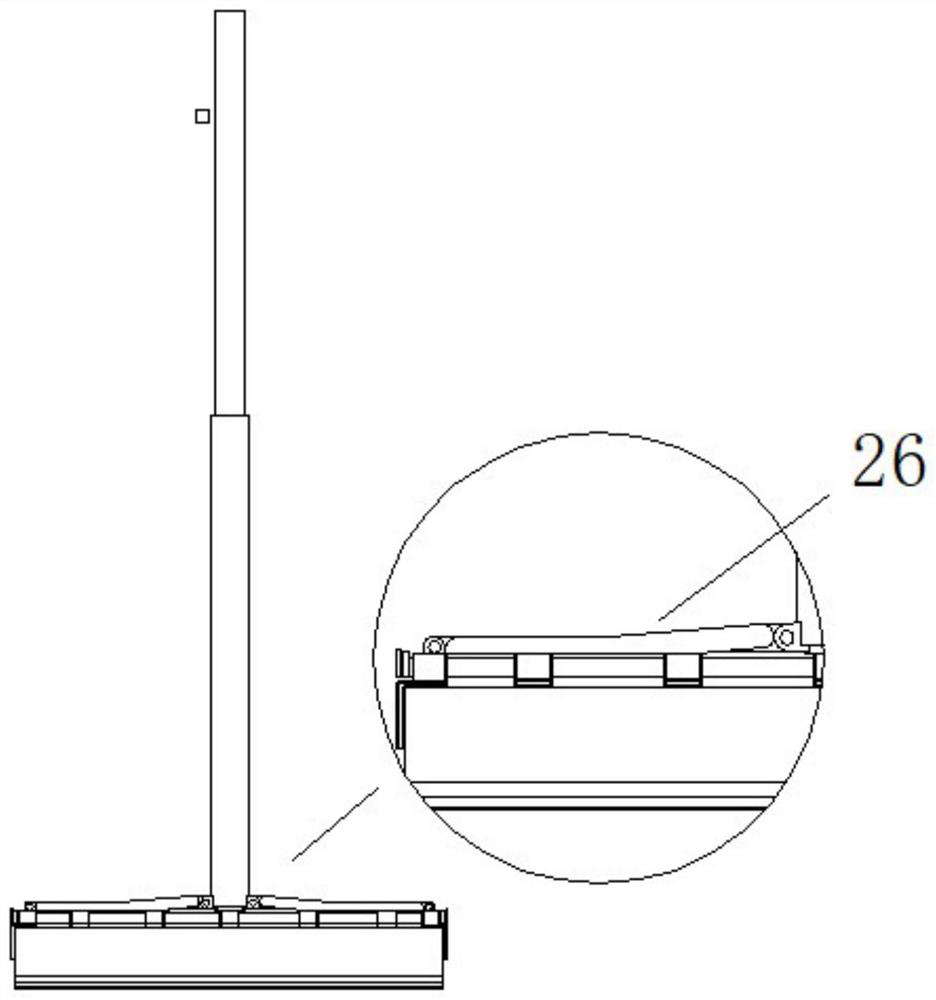

[0035] Such as Figure 2-5 As shown, the present embodiment provides a mop including a collodion head 20, a rotating shaft 21 or 27, a mop panel 22, a mounting block 23, a track 24, a plug 25, a moving arm 26, a grip 28 and a mop rod 29.

[0036] In this embodiment, the outer diameter of the mop rod 29 should be slightly smaller than the inner diameter of the handle 28, so that the mop rod 29 can be smoothly put into the handle 28 and can be pulled flexibly in the handle 28. The mop panel 22 is provided with a groove for the movement arm 26 to pass through, while the mop panel 22 both sides are provided with plugs 25, and the middle part of the upper end face of the mop panel 22 is fixedly connected with the pipe 29 to realize the overall positioning of the mop. A plug 25 is provided, and the plug 25 is used to limit the lateral movement of the moving arm 27, and at the same time prevent sundries from entering the interior of the mop head. figure 2 The track 24 shown in the ...

Embodiment 2

[0043] refer to Figure 6-11 As shown, the difference between this embodiment and Embodiment 1 is that six spring structures 34 are arranged on the sliding track, and three spring structures are respectively arranged on the left and right sides. The flexibility and other aspects are adjusted. The middle part of the upper end surface of the mop panel is rotated with a short rod structure, and the lower rod 37 is fixedly connected with the short rod. Structures such as auxiliary wheels 36 and steel wire ropes 35 are provided, through which the automatic return of the collodion head 31 can be realized and the convenience of use can be improved.

[0044] Such as Figure 6 As shown, the spring 34 is arranged on the track, and the spring can realize compression and reset along the track, and the steel wire rope 35 bypasses the structure of the auxiliary wheel 36 to realize the change of the extension direction of the steel wire rope and reduce friction loss at the same time.

[0...

Embodiment 3

[0051] refer to Figure 12-16 , The mop provided in this embodiment includes any collodion head, track, and mop panel structure as described above, and also includes the short rod structure in Embodiment 2, which can realize the rotation of the mop rod.

[0052] The difference from the previous two embodiments is that there are grooves inside the mounting blocks 40 on both sides, and an inclined slope structure is arranged inside the grooves, which can be used with a squeeze bucket, and there are protruding parts 44 inside the squeeze bucket as abutment part, the bottom of the protruding part 44 is fixedly connected with the inner bottom of the squeezing bucket. During the water squeezing process, the upper side of the protruding part 44 cooperates with the inclined slope of the groove to realize the inward movement of the mounting blocks 40 on both sides.

[0053] In this embodiment, the spring structure of Embodiment 2 can be set on the track, and the corresponding spring c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com