Process and device for zero discharge of wastewater in pervaporation process

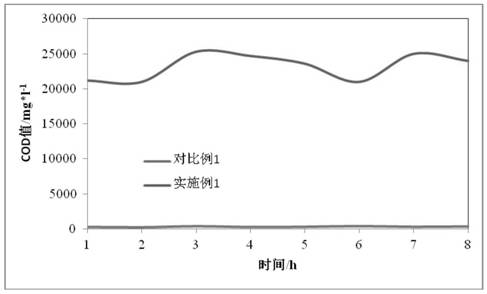

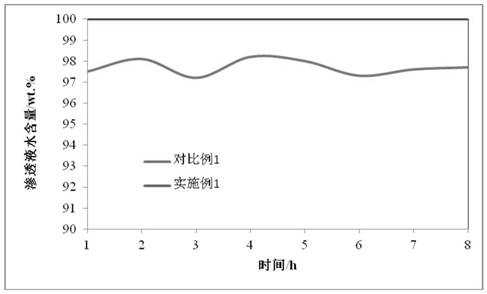

A technology of pervaporation and zero discharge, applied in the direction of permeation/dialysis water/sewage treatment, semi-permeable membrane separation, multi-stage water treatment, etc., can solve the problem of high COD in wastewater, achieve low input cost, increase yield, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]An infiltrated vaporization process wastewater, including raw material storage tank 1, raw material pump 2, heat exchanger 3, first permeable can 4, first vacuum pump 5, permeate condenser 6, permeate pump 7, permeation Heat 8, second permeability tank 9, second vacuum pump 10;

[0031]The raw material storage tank 1, a raw material pump 2, a heat exchanger 3, a first permeable tank 4, a first vacuum pump 5, a permeate condenser 6, a permeation liquid pump 7, a permeate heat transfer device 8, a second permeable tank 9 The second vacuum pump 10 is connected to the tail of the pipe, and the exit of the second vacuum pump 10 is connected to the inlet of the raw material storage tank 1.

[0032]In this embodiment, the first permeable tank 4 is fixedly connected to a preferred water film, and the first permeable canister is fixedly connected to the first water pipe 11, the second water pipe 12; the first water pipe 11 The first solvent can be fixed to the exit, and the outlet of the sec...

Embodiment 2

[0038]An infiltrated vaporization process wastewater, including raw material storage tank 1, raw material pump 2, heat exchanger 3, first permeable can 4, first vacuum pump 5, permeate condenser 6, permeate pump 7, permeation Heat 8, second permeability tank 9, second vacuum pump 10;

[0039]The raw material storage tank 1, a raw material pump 2, a heat exchanger 3, a first permeable tank 4, a first vacuum pump 5, a permeate condenser 6, a permeation liquid pump 7, a permeate heat transfer device 8, a second permeable tank 9 The second vacuum pump 10 is connected to the tail of the pipe, and the exit of the second vacuum pump 10 is connected to the inlet of the raw material storage tank 1.

[0040]In an embodiment, the first permeable tank 4 is fixedly connected to a priority water film, and the first osmotic can be fixedly connected to the first water pipe 11, the second water pipe 12; the exit of the first water pipe 11 The first solvent can there is a first solvent can, and the exit of...

Embodiment 3

[0046]An infiltrated vaporization process wastewater, including raw material storage tank 1, raw material pump 2, heat exchanger 3, first permeable can 4, first vacuum pump 5, permeate condenser 6, permeate pump 7, permeation Heat 8, second permeability tank 9, second vacuum pump 10;

[0047]The raw material storage tank 1, a raw material pump 2, a heat exchanger 3, a first permeable tank 4, a first vacuum pump 5, a permeate condenser 6, a permeation liquid pump 7, a permeate heat transfer device 8, a second permeable tank 9 The second vacuum pump 10 is connected to the tail of the pipe, and the exit of the second vacuum pump 10 is connected to the inlet of the raw material storage tank 1.

[0048]In an embodiment, the first permeable tank 4 is fixedly connected to a priority water film, and the first osmotic can be fixedly connected to the first water pipe 11, the second water pipe 12; the exit of the first water pipe 11 The first solvent can there is a first solvent can, and the exit of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com