Black talc nano particle modified polyamide composite nano-filtration membrane

A technology of nanoparticle modification and composite nanofiltration membrane, which is applied in membrane, membrane technology, semi-permeable membrane separation, etc. It can solve the problems of poor separation performance, low mechanical strength, and easy contamination of the membrane, and achieve low production cost, Excellent mechanical properties and the effect of improving water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

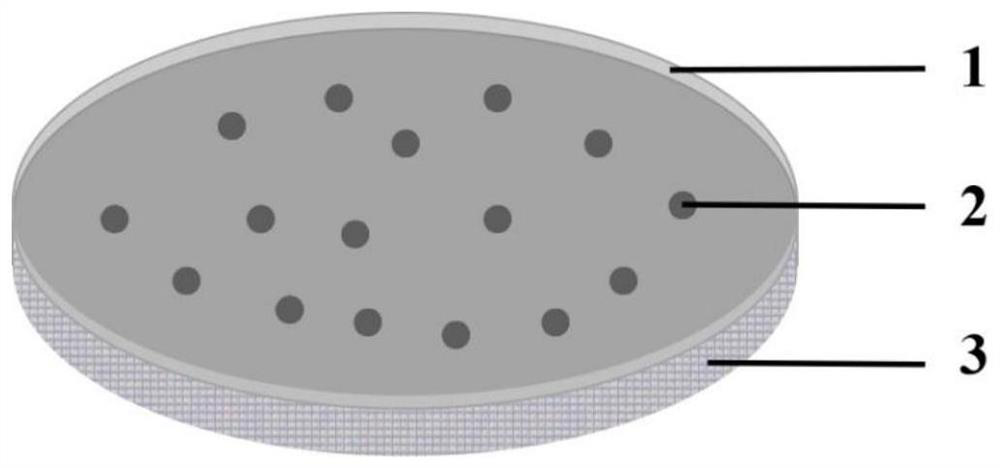

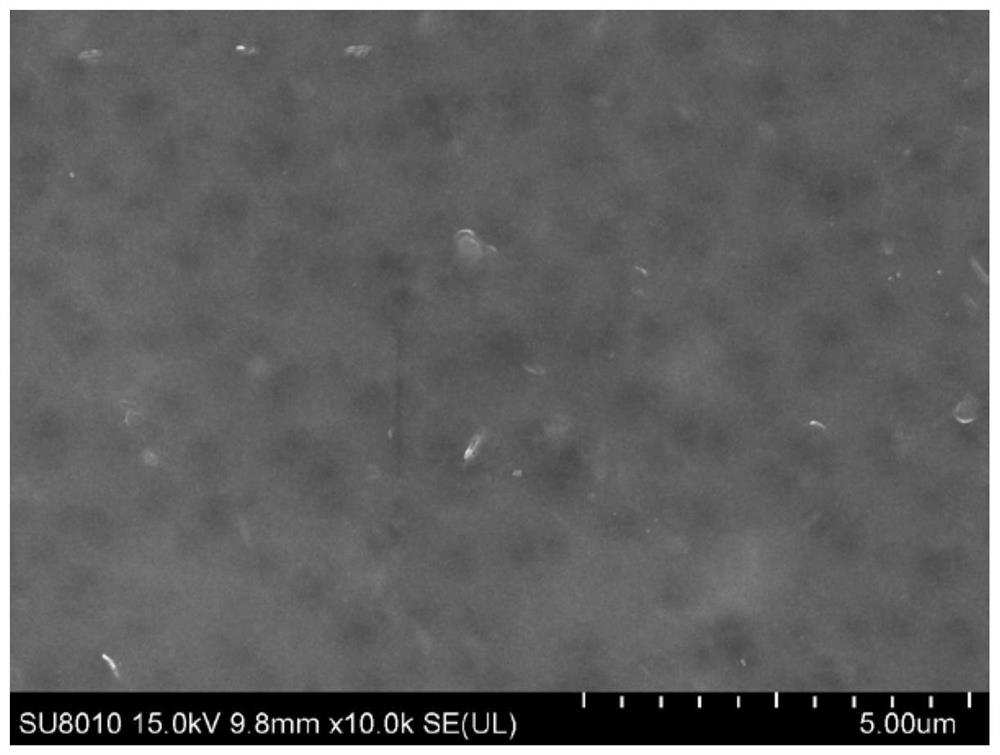

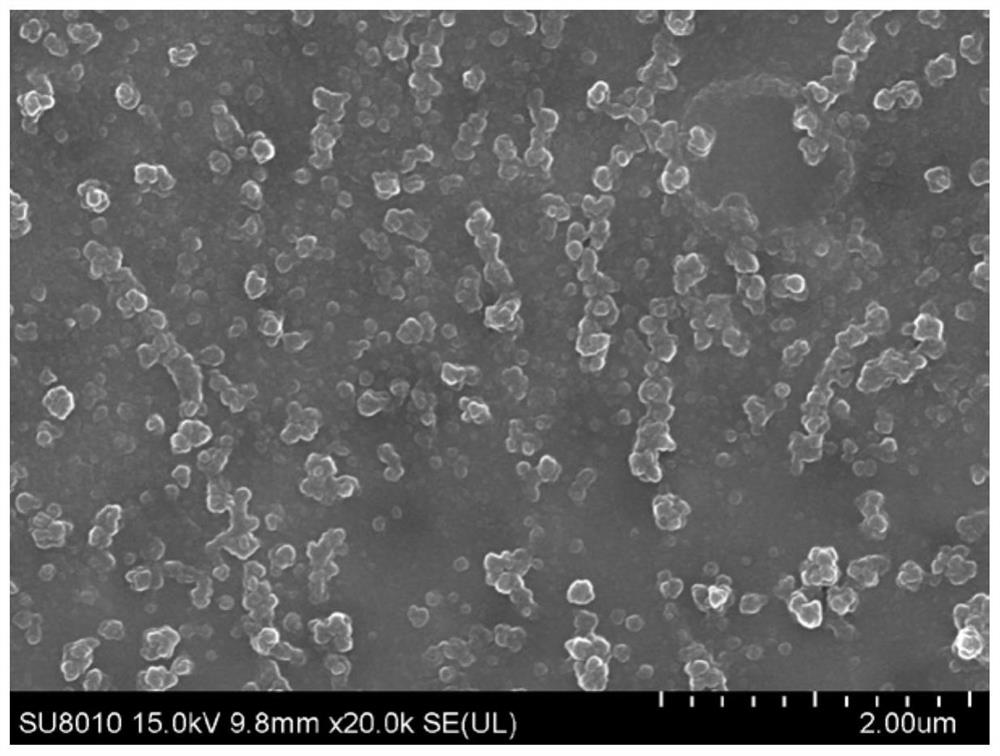

[0041] (1) 10g black talc (black talc originates from Guangfeng District, Shangrao City, Jiangxi Province) is ball milled, wet-grinded for 5h with ball mill 600r / min, washed with water and centrifugally dried to obtain 8.8g black talc nanoparticles (average particle diameter is 220nm ). Then add 0.369g of black talc nanoparticles into 20mL of N-methylpyrrolidone solvent, ultrasonic (100W 40KHz) for 1h to make it uniformly dispersed, then add 3.86g of polysulfone and stir to dissolve for 12h, let it stand for defoaming, and form a 28mL stable Uniform casting solution.

[0042] (2) Use a spatula to scrape 2mL of casting solution onto a glass plate, and quickly put it into a deionized water coagulation bath. After the phase inversion is complete, a 130cm 2 The black talc nanoparticles / polysulfone support layer, the black talc nanoparticles / polysulfone support layer was transferred to deionized water to continue the solvent exchange for 24 hours for later use.

[0043] (3) The bla...

Embodiment 2

[0046] (1) 10g black talc (black talc originates from Guangfeng District, Shangrao City, Jiangxi Province) is ball milled, wet-grinded with ball mill 600r / min for 5h, washed with water, and centrifugally dried to obtain 8.8g black talc nanoparticles (average particle diameter of 220nm). Then add 0.215g of black talc nanoparticles into 20mL of N-methylpyrrolidone solvent, ultrasonically (100W 40KHz) for 1.5h to make it evenly dispersed, then add 2.58g of polysulfone and stir to dissolve for 12h, let it stand for defoaming to form 26mL Stable and uniform casting solution.

[0047] (2) Use a spatula to scrape 2mL of casting liquid onto a glass plate, put it into a coagulation bath of deionized water quickly, and after the phase inversion is complete, put 130cm 2 The black talc nanoparticles / polysulfone support layer was transferred to deionized water to continue solvent exchange for 24 hours for later use;

[0048] (3) Immerse black talc nanoparticles / polysulfone porous support...

Embodiment 3

[0051] (1) 10g black talc (black talc originates from Guangfeng District, Shangrao City, Jiangxi Province) is ball milled, wet-grinded with ball mill 600r / min for 5h, washed with water, and centrifugally dried to obtain 8.8g black talc nanoparticles (average particle diameter of 220nm). Then add 0.826g of black talc nanoparticles into 15mL of N-methylpyrrolidone solvent, ultrasonic (100W 40KHz) for 1h to make it uniformly dispersed, then add 2.48g of polysulfone and stir to dissolve for 12h, let it stand for defoaming, and form a 27mL stable Uniform casting solution.

[0052] (2) Use a spatula to scrape 2mL of casting liquid onto a glass plate, put it into a coagulation bath of deionized water quickly, and after the phase inversion is complete, put 130cm 2 The black talc nanoparticles / polysulfone support layer was transferred to deionized water to continue solvent exchange for 24 hours for later use.

[0053] (3) Immerse black talc nanoparticles / polysulfone porous support me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com