Green regeneration method of electrolytic aluminum waste tank lining mixture

A waste tank lining and mixed material technology, applied in solid separation, grain treatment, flotation, etc., can solve the problem that does not involve the treatment of carbon blocks and refractory bricks in waste carbon cathodes, which is not conducive to cathode carbon blocks and refractory materials Separate recycling, environmental issues and other issues to achieve the effect of green and efficient recycling, convenient use of points, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

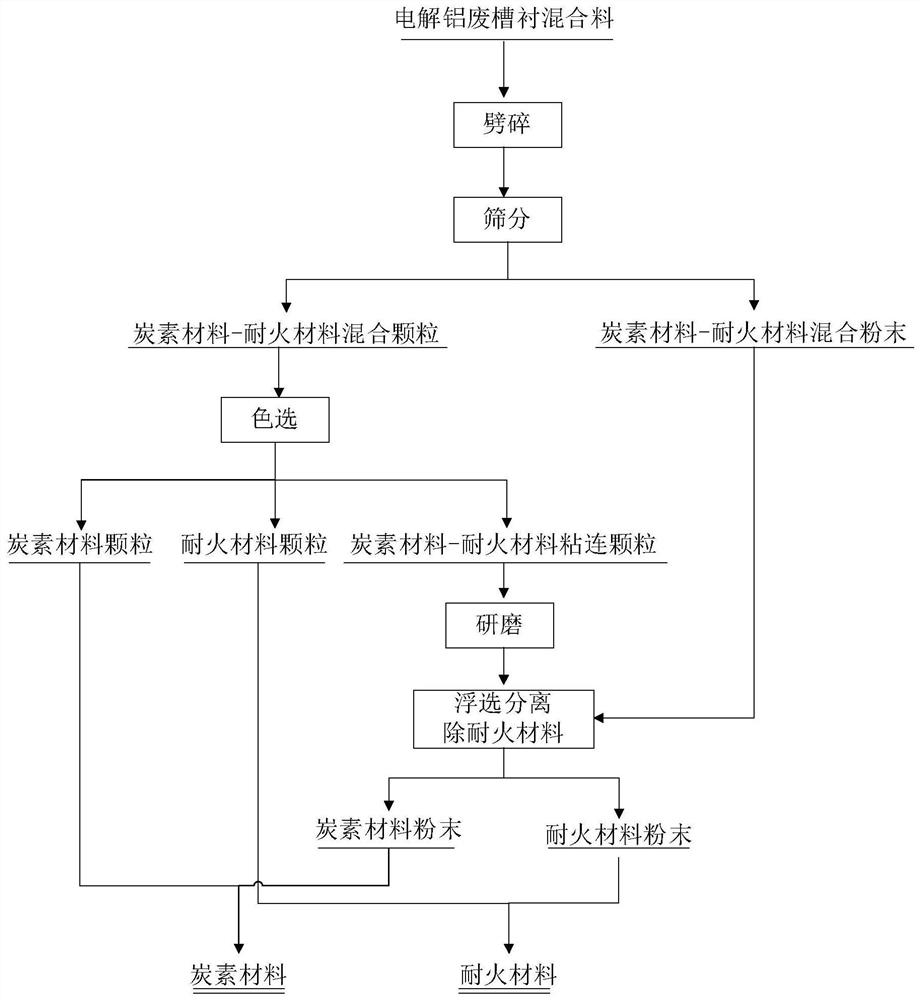

[0018] Embodiment 1: A kind of green regeneration method of electrolytic aluminum scrap liner mixture (see figure 1 ),Specific steps are as follows:

[0019] (1) chopping and sieving the electrolytic aluminum waste tank lining mixture to obtain carbon material-refractory mixed particles with a particle size of 3-6mm and carbon material-refractory mixed powder with a particle size less than 3mm;

[0020] (2) Carry out color sorting and sorting to step (1) carbon material-refractory material mixed particles to obtain carbon material particles, refractory material particles and carbon material-refractory material sticking particles; wherein the color selection adopts a photoelectric color sorter, and the color sorting The air pressure is 0.4Mpa, the feed rate is 80%; the sensitivity is 220; the background plate is set to 500; the color difference type is white / black; the RGB pixel ranges of carbon materials are 70, 70, and 80; the RGB pixel ranges of refractory materials are 120 ...

Embodiment 2

[0022] Embodiment 2: A kind of green regeneration method of electrolytic aluminum waste tank liner mixture (see figure 1 ),Specific steps are as follows:

[0023] (1) chopping and sieving the electrolytic aluminum waste tank lining mixture to obtain carbon material-refractory mixed particles with a particle size of 3-10mm and carbon material-refractory mixed powder with a particle size less than 3mm;

[0024] (2) Carry out color sorting and sorting to step (1) carbon material-refractory material mixed particles to obtain carbon material particles, refractory material particles and carbon material-refractory material sticking particles; wherein the color selection adopts a photoelectric color sorter, and the color sorting The air pressure is 0.1Mpa, the feeding amount is 30%; the sensitivity is 160; the background plate is set to 400; the color difference type is white / black; the carbon material RGB pixel range is 40, 50, 55 respectively; the refractory material RGB pixel range...

Embodiment 3

[0026] Embodiment 3: A kind of green regeneration method of electrolytic aluminum waste tank liner mixture (see figure 1 ),Specific steps are as follows:

[0027] (1) chopping and sieving the electrolytic aluminum waste tank lining mixture to obtain carbon material-refractory mixed particles with a particle size of 3-8mm and carbon material-refractory mixed powder with a particle size less than 3mm;

[0028] (2) Carry out color sorting and sorting to step (1) carbon material-refractory material mixed particles to obtain carbon material particles, refractory material particles and carbon material-refractory material sticking particles; wherein the color selection adopts a photoelectric color sorter, and the color sorting The air pressure is 0.3Mpa, the feeding amount is 50%; the sensitivity is 200; the background plate is set to 450; the color difference type is white / black; the RGB pixel range of carbon material is 50, 60, 70 respectively; the RGB pixel range of refractory mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com