Experimental device and method for researching jet flow impact characteristics of reactor core outlet of fast reactor

A technology of jet impact and core exit, which is applied in the field of fast reactor core, can solve the problems of not considering the impact of the impact of the central measurement column of the upper chamber on the core, and the large difference in the structure of the core exit, so as to achieve flexible arrangement of measurement points, Improved heat utilization, precision and high degree of visualization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

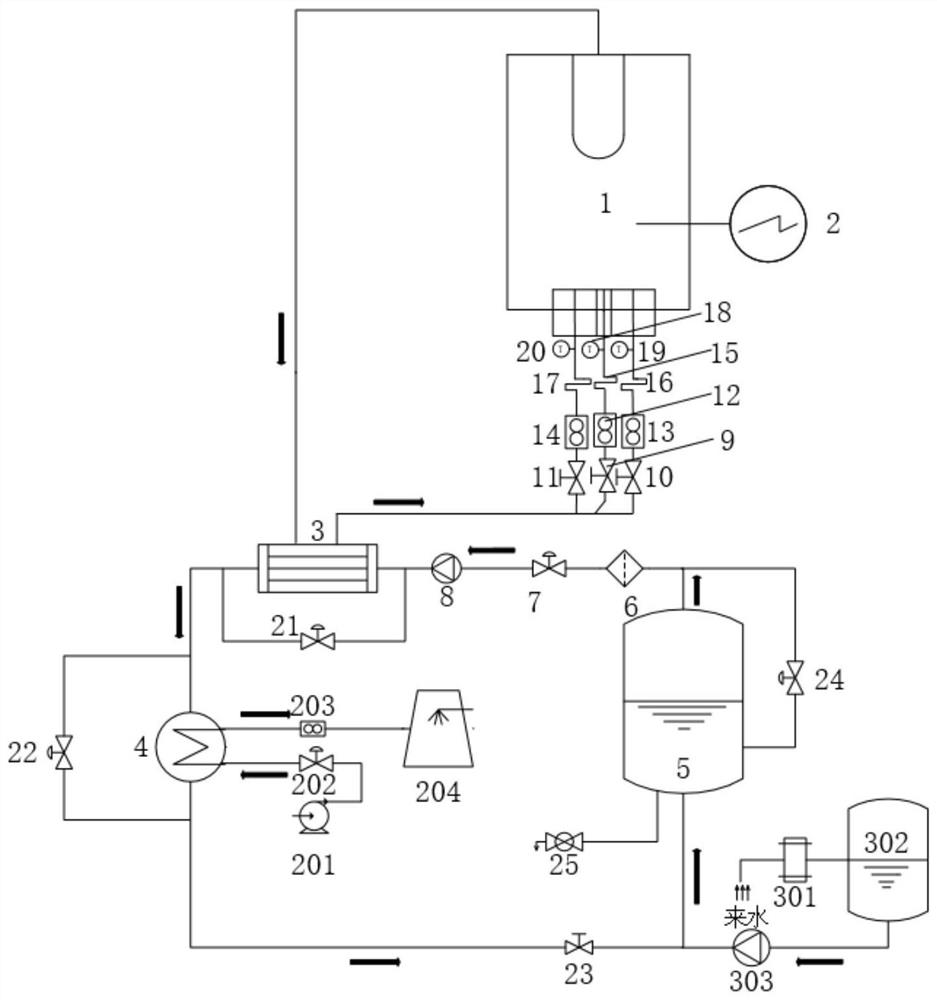

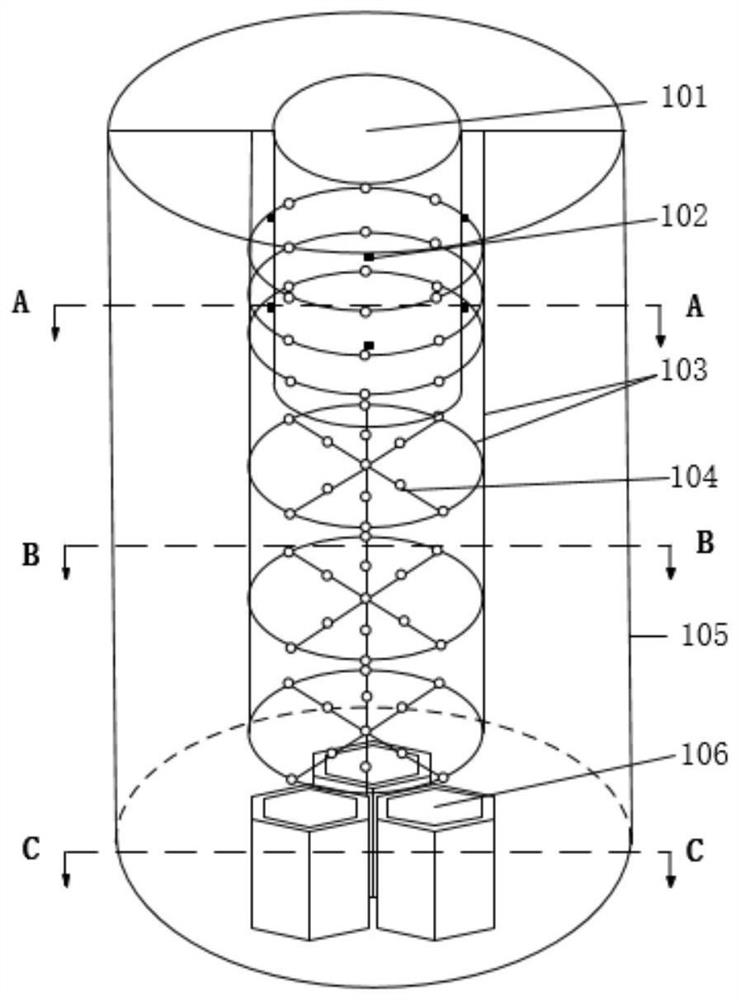

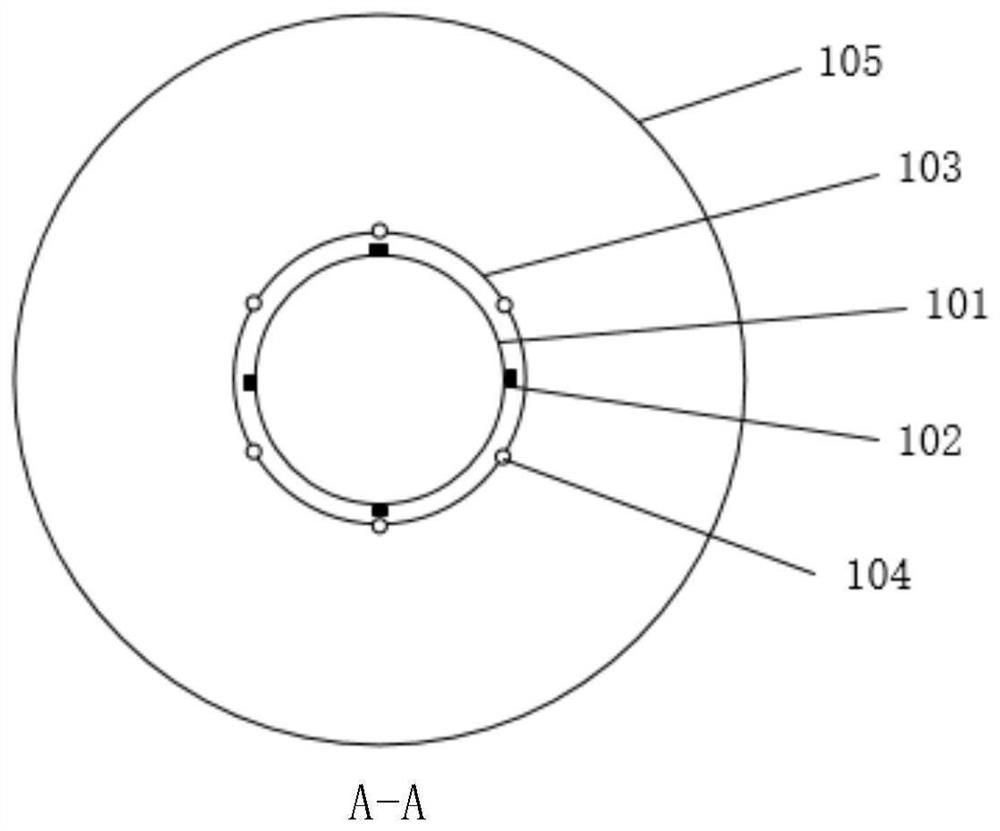

[0037] Such as figure 1 As shown, an experimental system for studying jet impingement characteristics at the exit of the fast reactor core includes a jet impingement chamber 1, a regenerator 3, and three branches connecting the inlet of the jet impingement chamber 1 and the tube side outlet of the regenerator 3. Pipeline, the pipe connecting the outlet of the jet impact chamber 1 and the inlet of the shell side of the regenerator 3, the condenser 4, the pipe connecting the outlet of the shell side of the regenerator 3 and the inlet of the shell side of the condenser 4, the water storage tank 5, connecting the water storage tank 5 outlet and the main pipeline of the regenerator 3 pipe side inlet, the filter 6 installed on the main pipeline, the first regulating valve 7 and the first plunger pump 8 constitute the jet impact main circuit of the test system, in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com