Rapid post-heating molding device for semiconductor chip packaging

A chip packaging and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of adjusting chip forming speed, chip surface quality is easily affected, and rapid prototyping cannot be performed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

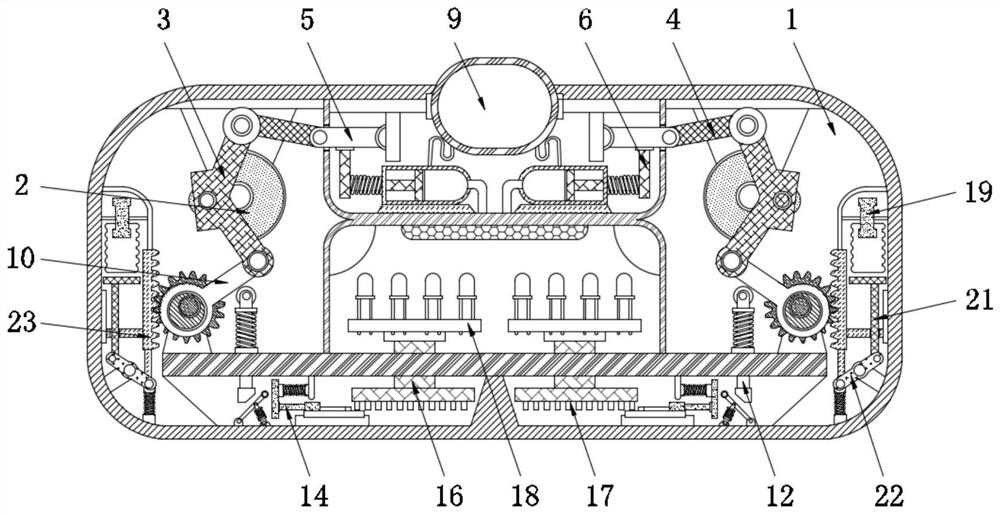

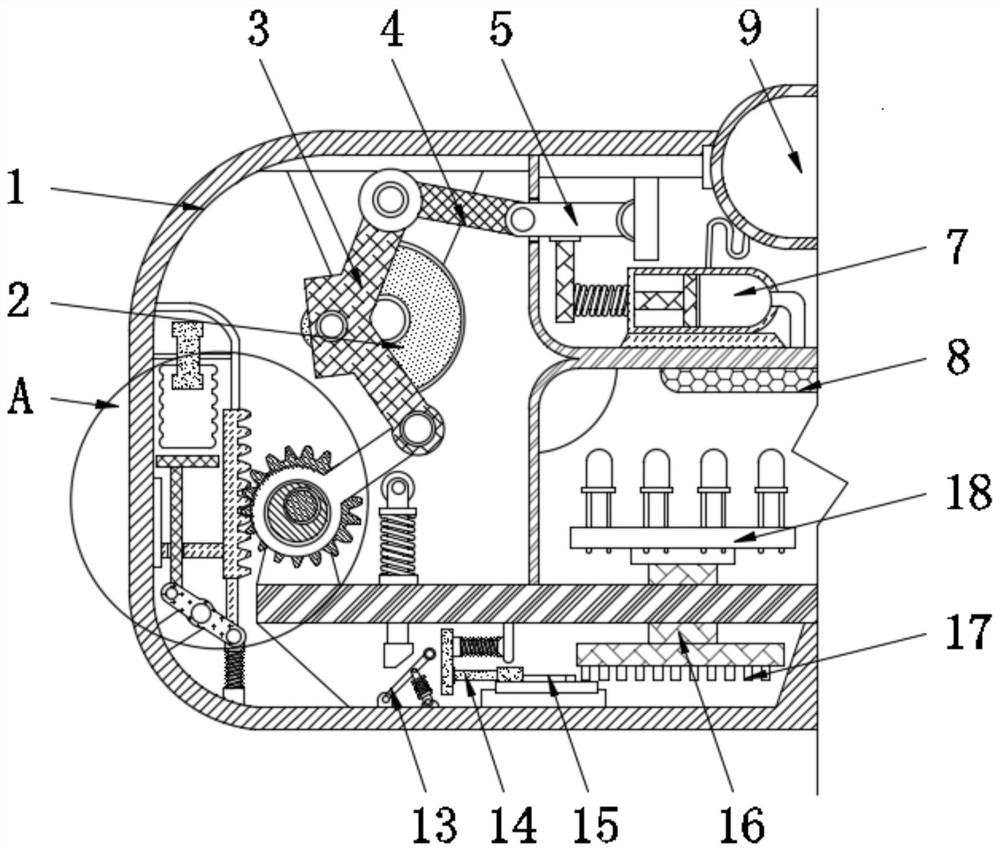

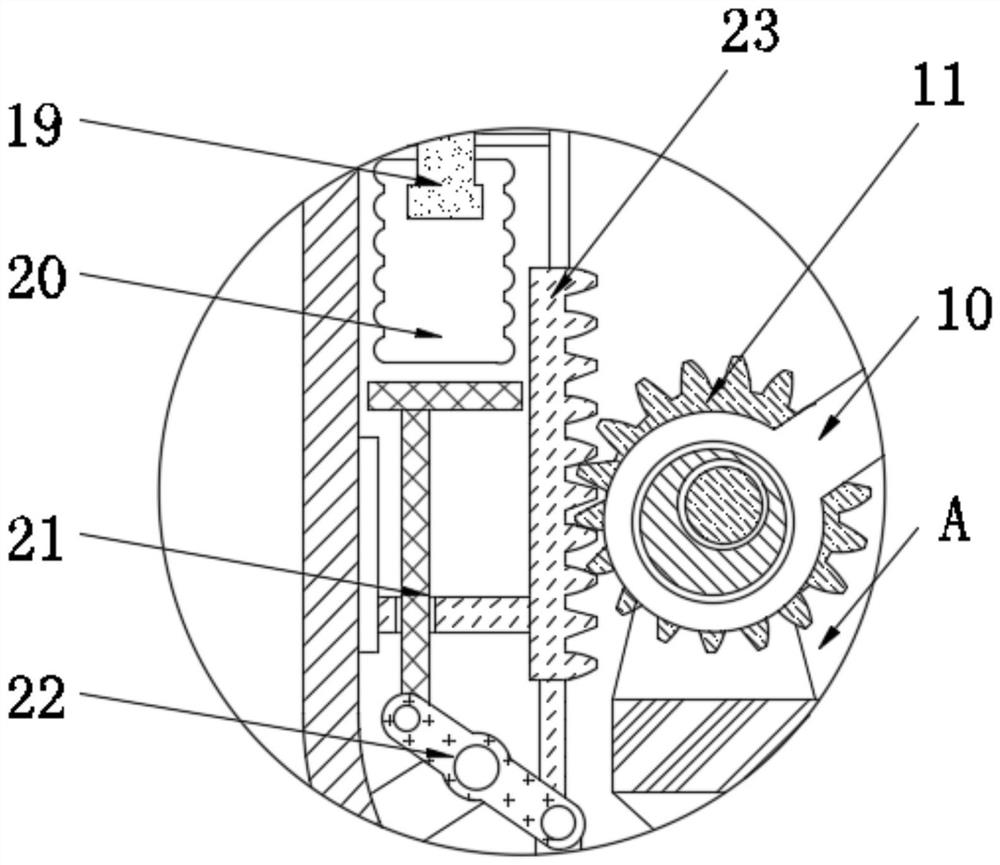

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] The invention provides a rapid prototyping device after heating for semiconductor chip packaging, as attached figure 1 to attach Figure 4 Shown: Including the forming chamber 1, the inside of the forming chamber 1 is installed with a fan-shaped plate 2, which is fixedly connected with the drive shaft, and the front surface of the fan-shaped plate 2 is movable. A movable plate 3 is installed, and the top of the movable plate 3 is movable Connected with a bracket 4, the end of the bracket 4 is movably connected with a slide bar 5, the movable plate 3 is a V-shaped structure, and the adjacent slide bars 5 are arranged symmetrically with respect to the center of the hot air chamber 9, and the slide bar 5 is slidably installed in the forming chamber 1 The inner wall of the sliding rod 5 is fixedly installed with a piston plate 6, the piston plate 6 is slidably installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com