Direct coupling type water-jet guided laser coupling system and method

A coupling system and direct-coupled technology, applied in the field of direct-coupled water-guided laser coupling systems, can solve the deviation of the coaxiality between the laser spot and the red light, which is not conducive to reducing the size and weight of the device, and is not conducive to the laser and water fiber. Focusing and other problems, to achieve the effect of simplifying the laser alignment operation, convenient disassembly and assembly, and reducing the difficulty of alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

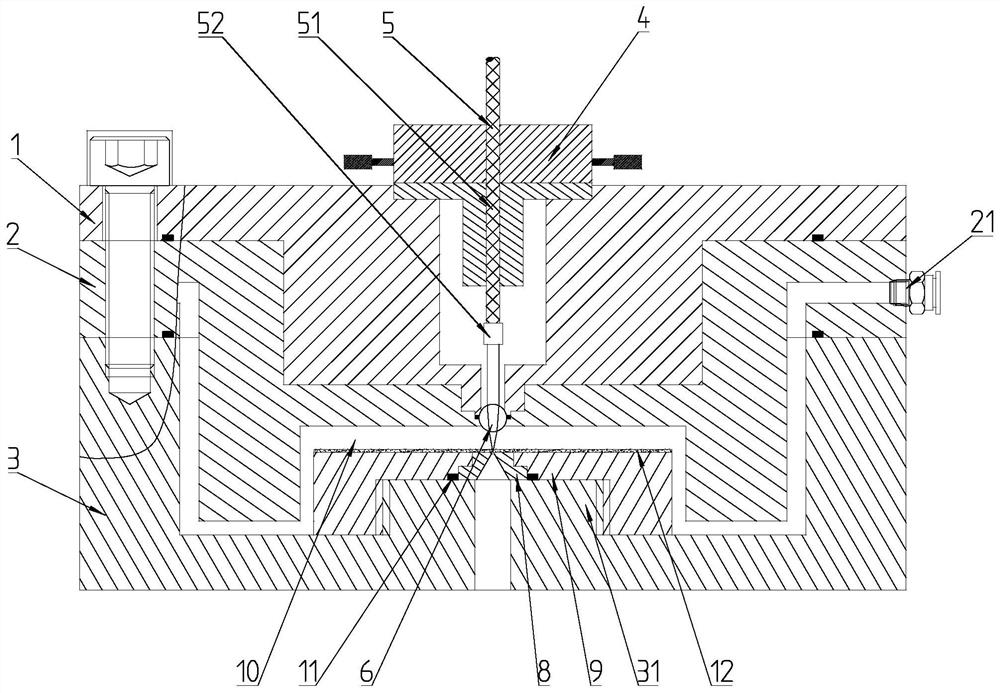

[0037] A direct-coupled water-conducting laser coupling system described in this embodiment, as attached figure 1 As shown, its main body includes a light transmission cavity 1 , a lens fixing cavity 2 , a nozzle holder 3 , a three-axis optical moving platform 4 , a laser collimation system 5 , a ball lens 6 , a nozzle 8 , and a nozzle cover 9 .

[0038] The optical transmission cavity 1, the lens fixed cavity 2, and the nozzle holder body 3 are vertically stacked coaxially from top to bottom to form a cylindrical coupling cavity, and the optical transmission cavity 1, the lens fixed cavity 2, and the nozzle holder body 3 are provided A plurality of installation holes, the installation holes are located close to the outer edge of the cylindrical coupling cavity, the screws pass through the light transmission cavity 1, the lens fixing cavity 2 in turn, and are screwed to the nozzle holder body 3. The cross-section of the optical transmission chamber 1 is a T-shaped structure, t...

Embodiment 2

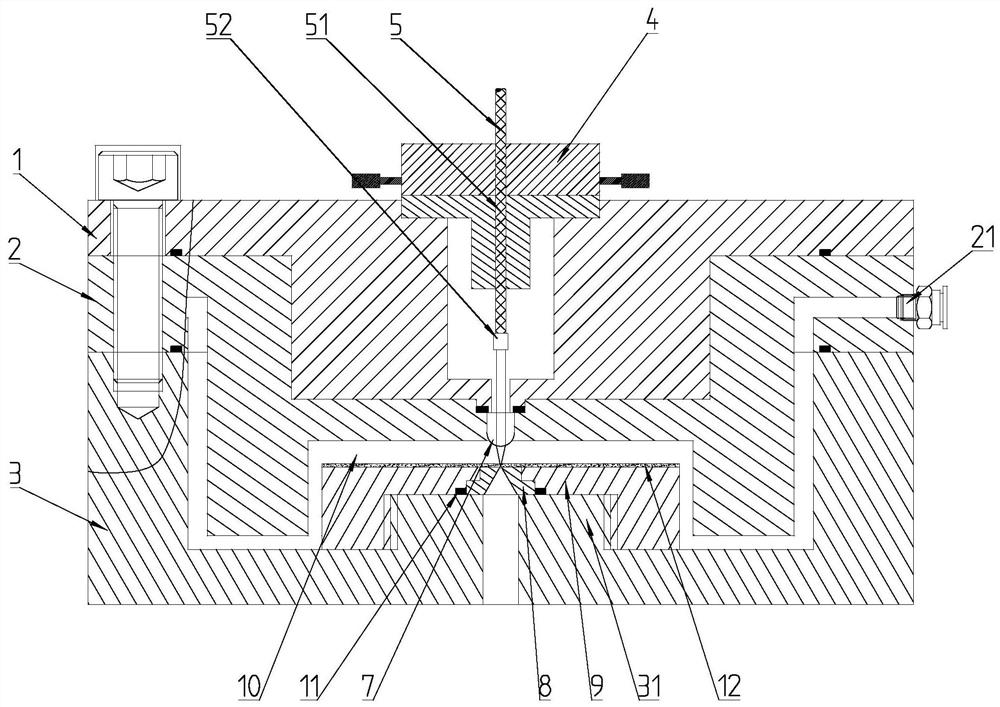

[0046] In this embodiment, the difference from Embodiment 1 is that the hemispherical lens 6 is adopted, and the hemispherical lens 6 is a cylindrical upper part and a hemispherical bottom structure, and the shape of the curved lens groove matches the hemispherical lens 6, as shown in figure 2 shown. The spherical surface at the bottom of the hemispherical lens 6 passes through the bottom surface of the lens fixing cavity 2, and the passing distance is less than the spherical radius.

[0047] A direct-coupled water-guided laser coupling method, based on the direct-coupled water-guided laser coupling system described in the above-mentioned embodiment 1 and embodiment 2, the coupling method includes the following steps:

[0048] S1: Turn on the laser collimation system 5 to emit the laser downward, observe the color-changing coating 12 composed of photochromic material above the nozzle 8 and the nozzle cover 9, and judge the position of the laser spot through the color-changing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com