Process method for improving crystallization granularity of carbonization reaction material in carbonization tower in sodium carbonate production

A technology of carbonization reaction and process method, applied in carbonate preparations and other directions, can solve problems such as affecting crystal particle size and particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

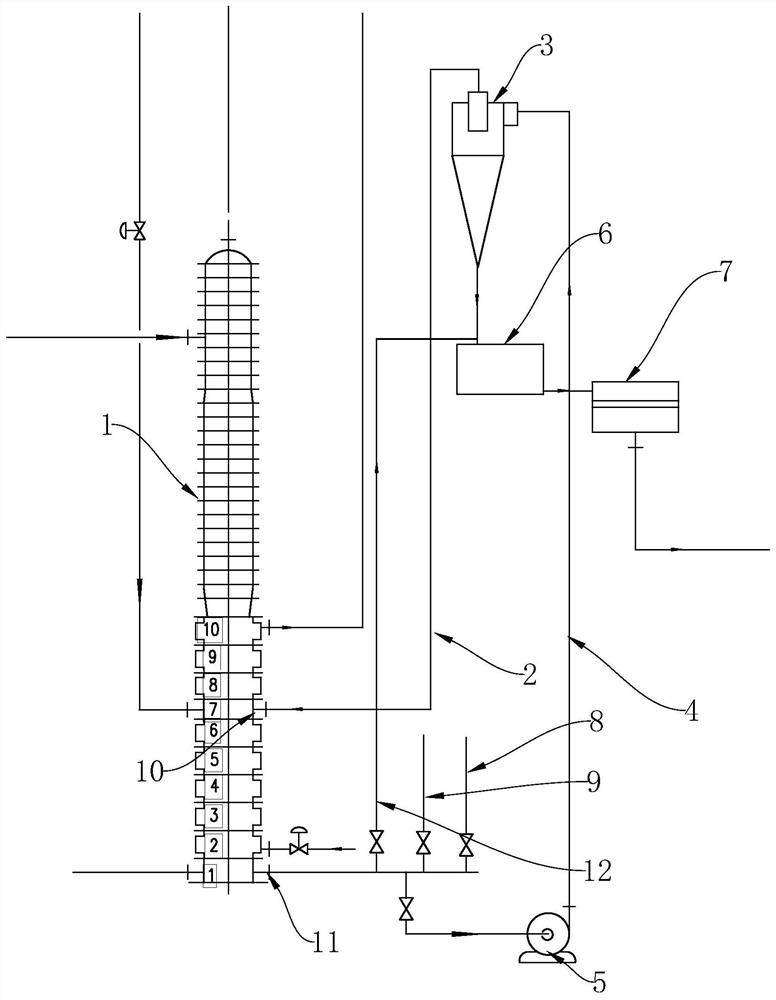

Method used

Image

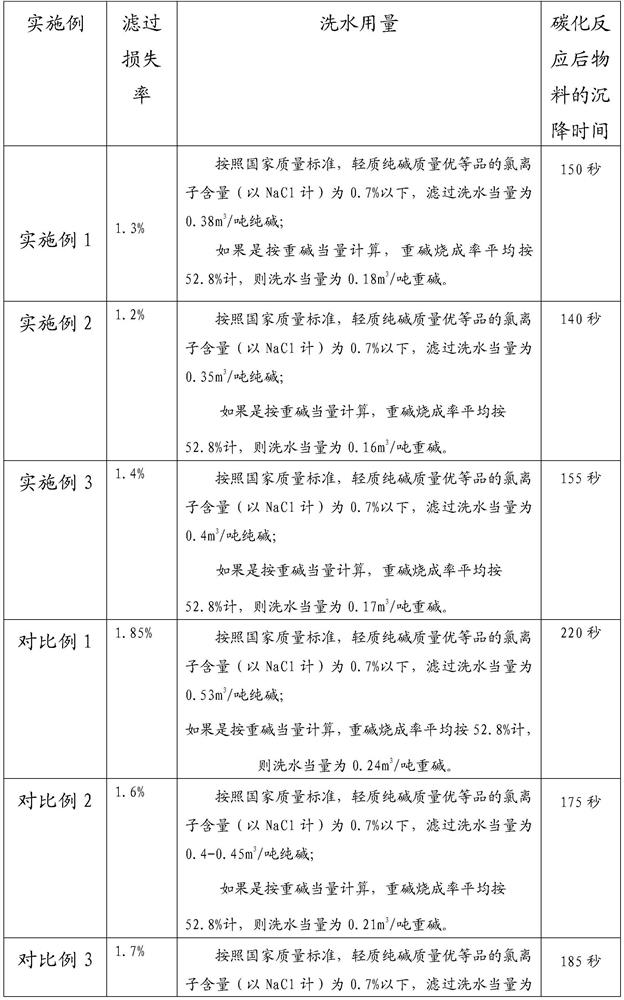

Examples

Embodiment 1

[0017] A process for increasing the crystallization size of the carbonization reaction material in the carbonization tower in the production of soda ash. The carbonization reaction material in the carbonization tower enters the separator through the material conveying pipeline, and the material liquid located in the upper part of the separator after separation enters through the return pipe. The interior of the carbonization tower participates in the carbonization reaction.

[0018] The distance between the center of the reflux port connected with the reflux pipe on the carbonization tower and the bottom of the carbonization tower is 944.5 cm.

[0019] Wherein the distance between the center of the outlet of the carbonization tower connected with the material delivery pipeline and the bottom of the carbonization tower is 30cm.

[0020] Among them, there is a material delivery pump on the material delivery pipeline, the head of the material delivery pump is 42m, and the flow ra...

Embodiment 2

[0022] A process for increasing the crystallization size in the carbonization tower in the production of soda ash. The carbonized material in the carbonization tower enters the separator through the material conveying pipeline, and the material liquid at the upper part of the separator enters the interior of the carbonization tower through the return pipe after separation. Participate in carbonization reactions.

[0023] Wherein the distance between the center of the reflux port connected with the reflux pipe on the carbonization tower and the bottom of the carbonization tower is 1100.5 cm.

[0024] Wherein the distance between the center of the discharge port connected with the material conveying pipeline on the carbonization tower and the bottom of the carbonization tower is 28cm.

[0025] Wherein the material conveying pipeline is provided with a material conveying pump, the head of the material conveying pump is 45m, and the flow rate is 22m 3 / h, the outlet pressure is a...

Embodiment 3

[0027] A process for increasing the crystallization size in the carbonization tower in the production of soda ash. The carbonized material in the carbonization tower enters the separator through the material conveying pipeline, and the material liquid at the upper part of the separator enters the interior of the carbonization tower through the return pipe after separation. Participate in carbonization reactions.

[0028] Wherein the distance between the center of the reflux port connected with the reflux pipe on the carbonization tower and the bottom of the carbonization tower is 1234.5 cm.

[0029] Wherein the distance between the center of the outlet of the carbonization tower connected with the material delivery pipeline and the bottom of the carbonization tower is 30cm.

[0030] The head of the material transfer pump is 48m, and the flow rate is 18m 3 / h, the outlet pressure is about 0.6MPa.

[0031] Wherein the separator in the embodiment 1-3 comprises a body, and the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com