A durable steel slag concrete and its preparation process

A steel slag concrete and durability technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of short service life of pavement and poor carbonization resistance of steel slag concrete, and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

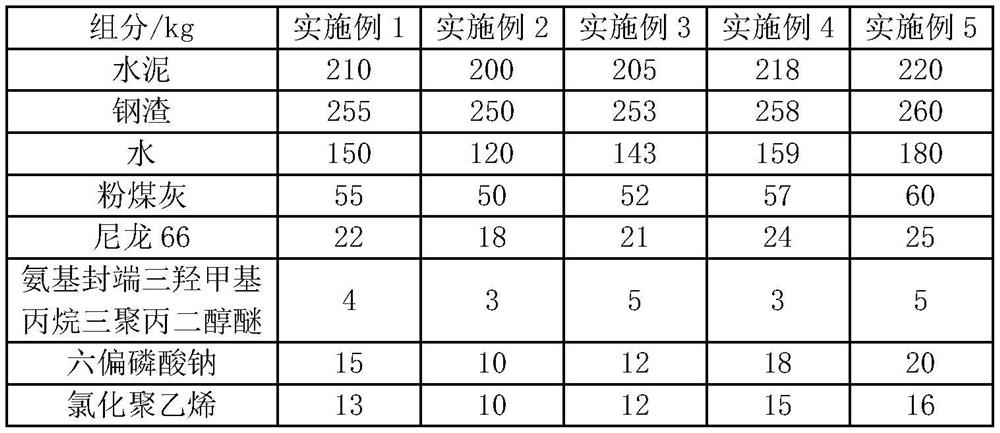

Embodiment 1

[0044] A durable steel slag concrete, comprising the following raw materials in parts by mass obtained by stirring and mixing:

[0045] 210 parts of cement,

[0046] 255 parts of steel slag,

[0047] 150 parts of water,

[0048] 55 parts of fly ash,

[0049] 22 parts of nylon 66, wherein nylon 66 is modified nylon 66, and the particle size of modified nylon 66 is 250 μm.

[0050] The amine chain extender is preferably 4 parts of amino-terminated trimethylolpropane tripropylene glycol ether,

[0051] The dispersant is preferably 15 parts of sodium hexametaphosphate,

[0052] The toughening agent is preferably 13 parts of chlorinated polyethylene,

[0053] The preparation of modified nylon 66 comprises the following steps:

[0054] S1: Nylon 66 and amino-terminated trimethylolpropane tripropylene glycol ether were mixed at high speed for 30 minutes to obtain a premix;

[0055] S2: Add the pre-mixture to a twin-screw extruder for melt reaction and extrusion, and the extrus...

Embodiment 6

[0080] A durable steel slag concrete, based on Example 1, N,N-bis(2-hydroxypropyl)aniline is selected as the amine chain extender, and the rest of the operation steps and parameters are the same as in Example 1.

Embodiment 7

[0082] A kind of durable steel slag concrete, based on the basis of Example 1, the amine chain extender is selected from 3,3'-dichloro-4,4-diamino-diphenylmethane, and the rest of the operation steps and parameters are the same as those in the implementation Example 1 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com