Polymer putty, putty coating, preparation method, putty coating and application

A technology of polymer and putty, which is applied in the field of putty coating and application, polymer putty, putty coating and preparation, can solve problems such as brittleness, poor willfulness, low physical properties, energy waste, etc. Broad application prospects, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

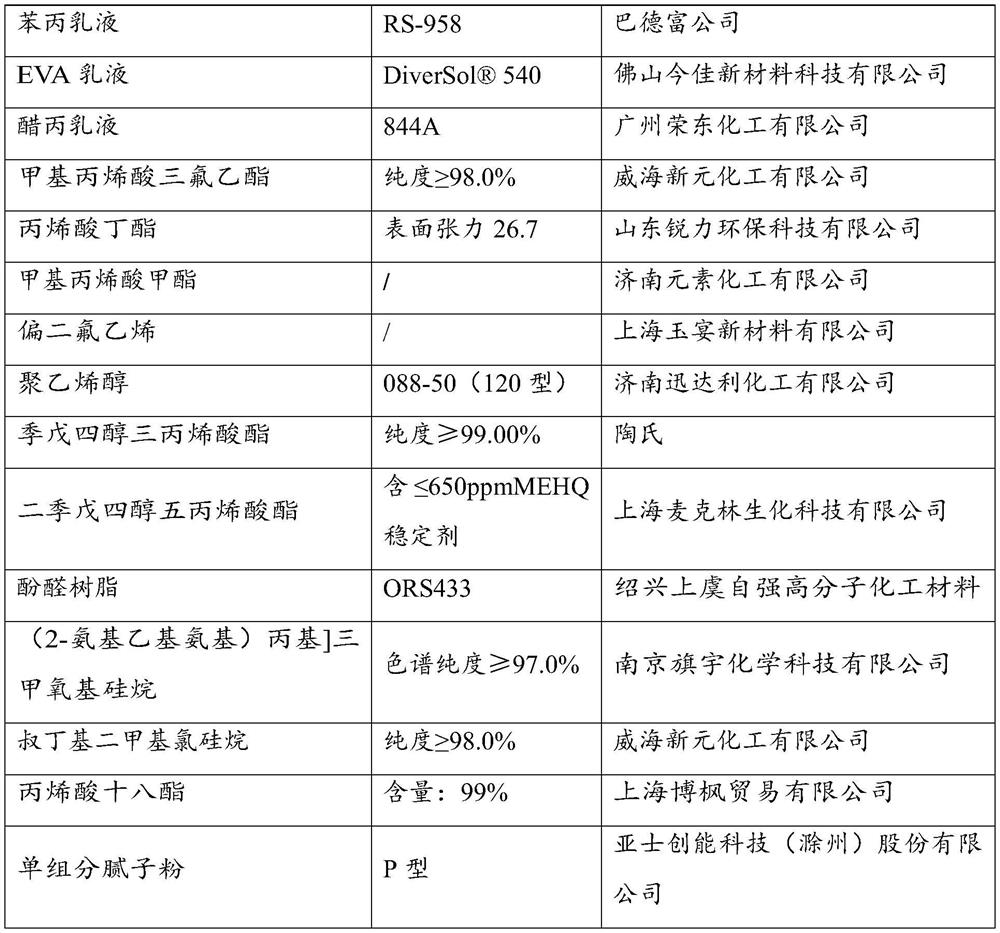

[0054] As an optional embodiment of the present invention, the polymer putty includes the following raw materials by mass fraction:

[0055] Emulsion 40-55%, trifluoroethyl methacrylate 0.1-0.6%, butyl acrylate 0.1-0.5%, vinylidene fluoride 0.5-1.0%, polyvinyl alcohol 1.0-3.0%, cross-linking agent 20-40% , [3-(2-aminoethylamino)propyl]trimethoxysilane 5-12% and octadecyl acrylate 8-15%;

[0056] Wherein, the emulsion includes any one or a combination of at least two of styrene-acrylic emulsion, pure acrylic emulsion or EVA emulsion; the crosslinking agent includes pentaerythritol triacrylate and / or dipentaerythritol pentaacrylate.

[0057] By further limiting the weight of each raw material, the performance of the polymer putty is more excellent in all aspects.

[0058] According to a second aspect of the present invention, also provide the preparation method of above-mentioned polymer putty, comprise the following steps:

[0059] The raw materials in the formulation amount ...

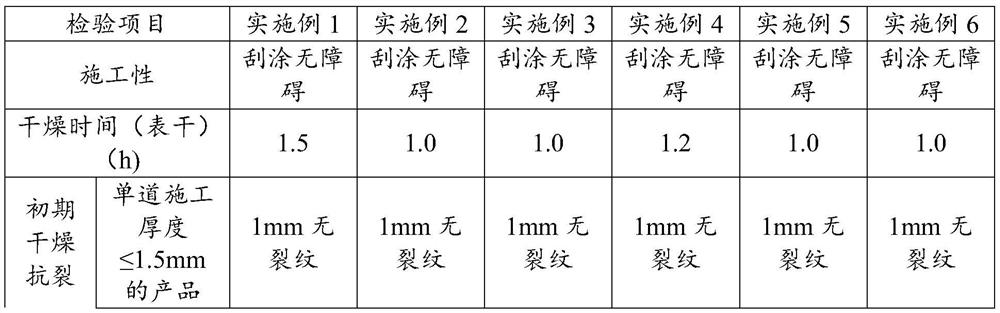

Embodiment 1

[0080] The present embodiment provides a polymer putty, made of the following raw materials by mass fraction:

[0081] Emulsion 50%, trifluoroethyl methacrylate 0.2%, butyl acrylate 0.1%, vinylidene fluoride 0.5%, polyvinyl alcohol 1.5%, crosslinking agent 28%, [3-(2-aminoethylamino) Propyl]trimethoxysilane 5% and stearyl acrylate 14.7%.

[0082] Wherein, the emulsion is styrene-acrylic emulsion, and the crosslinking agent is pentaerythritol triacrylate.

Embodiment 2

[0084] The present embodiment provides a polymer putty, made of the following raw materials by mass fraction:

[0085] Emulsion 50%, trifluoroethyl methacrylate 0.4%, butyl acrylate 0.2%, vinylidene fluoride 0.8%, polyvinyl alcohol 1.8%, crosslinking agent 28%, [3-(2-aminoethylamino) Propyl]trimethoxysilane 10.3% and stearyl acrylate 8.5%.

[0086] Wherein, the emulsion is styrene-acrylic emulsion, and the crosslinking agent is pentaerythritol triacrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com