Concentrated long-acting antibacterial and anti-fouling PC master batch and preparation method thereof

A kind of masterbatch and long-acting technology, applied in the field of plastic masterbatch, can solve the problems of dangerous operation process, high cost of plastic masterbatch, not conforming to the concept of green and environmental protection production, and achieve no pollution to the environment, low cost and improved compatibility and the effect on the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A second aspect of the present invention provides a method for preparing concentrated long-acting antibacterial and antifouling PC masterbatches, at least including the following steps:

[0042] (1) Under the condition of 300-350°C, add compatibilizer and cationic polymer into the internal mixer and stir. The internal mixer maintains a nitrogen atmosphere. After reacting for 1-8 hours, add organic amine and stir, and react 1-8h, maintain a nitrogen atmosphere in the internal mixer to obtain substance A;

[0043] (2) Under the condition of 270-350°C, add polycarbonate and substance A into an internal mixer for internal mixing, and stir for 1-8 hours, and then blend and extrude granules through a screw extruder to obtain the product.

[0044] In addition, all raw materials used are commercially available unless otherwise stated.

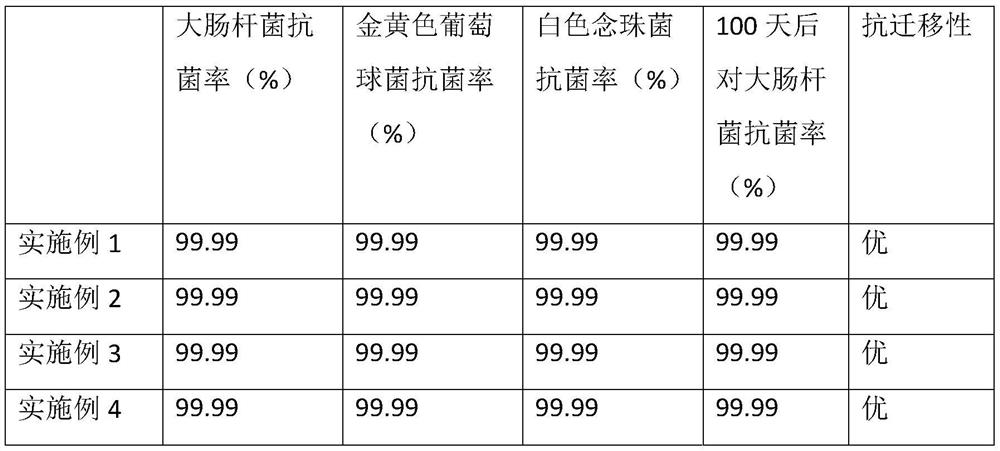

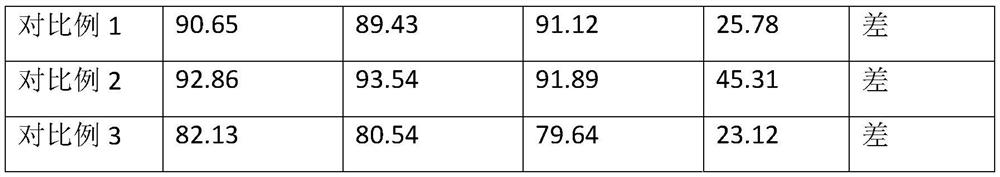

Embodiment 1

[0047] The first aspect of this embodiment provides a concentrated long-acting antibacterial and antifouling PC master batch. In parts by weight, its raw materials include 30 parts of polycarbonate and 1 part of antibacterial agent. The polycarbonate is purchased from Shanghai Ming Fu Plastic Chemical Co., Ltd., trademark: 2805.

[0048] The raw materials for the preparation of the antibacterial agent include 30 parts by weight of a cationic polymer, 30 parts of a compatibilizer and 35 parts of an organic amine. The cationic polymer is a guanidine salt, and the guanidine salt is polyhexamethylene biguanide Hydrochloride, the polyhexamethylene biguanide hydrochloride was purchased from Shanghai Dejian Chemical Co., Ltd., item number: 0050.

[0049] Described compatibilizer is maleic anhydride copolymer, and described maleic anhydride copolymer is binary maleic anhydride copolymer, and described binary maleic anhydride copolymer is styrene-maleic anhydride copolymer, and describ...

Embodiment 2

[0055] The first aspect of this embodiment provides a concentrated long-acting antibacterial and antifouling PC master batch. In parts by weight, its raw materials include 100 parts of polycarbonate and 4 parts of antibacterial agent. The polycarbonate is purchased from Shanghai Ming Fu Plastic Chemical Co., Ltd., trademark: 2805.

[0056] The raw materials for the preparation of the antibacterial agent include 30 parts by weight of a cationic polymer, 30 parts of a compatibilizer and 35 parts of an organic amine. The cationic polymer is a guanidine salt, and the guanidine salt is polyhexamethylene biguanide Hydrochloride, the polyhexamethylene biguanide hydrochloride was purchased from Shanghai Dejian Chemical Co., Ltd., item number: 0050.

[0057] Described compatibilizer is maleic anhydride copolymer, and described maleic anhydride copolymer is binary maleic anhydride copolymer, and described binary maleic anhydride copolymer is styrene-maleic anhydride copolymer, and descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com