Process for treating vegetable oil sludge by extraction and compression method

A vegetable oil and process technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of inability to recover high value-added oil products, high extraction agent costs, and high processing costs, and achieve large-scale continuous industrial production. The effect of the distillation time is too long or too short and meets the requirements of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

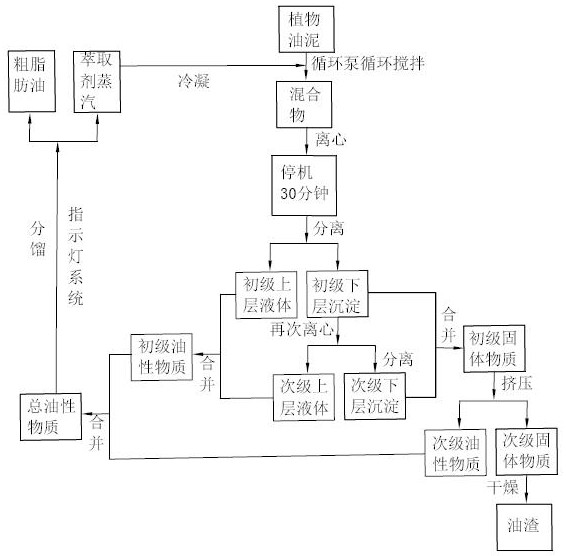

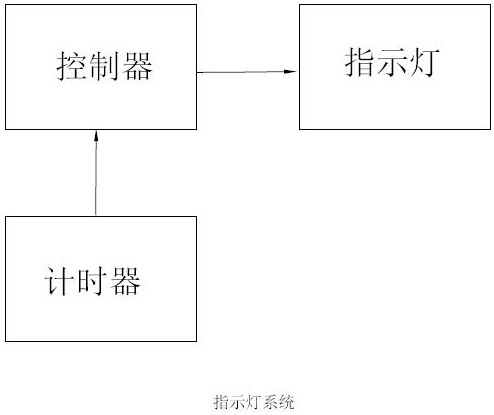

[0033] A kind of process of extracting and pressing method processing vegetable oil sludge, such as figure 1 with figure 2 shown, including the following steps:

[0034] S1. Extraction: Pour the vegetable sludge into the extraction tank, and add the extractant to the extraction tank (the mass percentage of the extractant and the vegetable sludge is 1:10), and then the mixture of the vegetable sludge and the extractant enters the circulating pump Dispersion, control the temperature in the circulating pump by means of water bath heating and keep it at 25°C and the impeller speed of the circulating pump is 1000 rpm; first start the circulating pump and run forward for 10 minutes to realize the dispersion of the material in the circulating pump, then stop 5 minutes is to prevent the heat generated during the stirring process from causing the temperature inside the circulation pump to rise, thus causing the oil in the vegetable sludge to oxidize and deteriorate under high tempera...

Embodiment 2

[0038] A kind of process of extracting and pressing method processing vegetable oil sludge, such as figure 1 with figure 2 shown, including the following steps:

[0039] S1. Extraction: Pour the vegetable sludge into the extraction tank, and add the extractant to the extraction tank (the mass percentage of the extractant and the vegetable sludge is 1:10), and then the mixture of the vegetable sludge and the extractant enters the circulating pump Dispersion, the temperature in the circulation pump is controlled by water bath heating to keep at 30°C and the impeller speed of the circulation pump is 1500 rpm; first start the circulation pump and run forward for 10 minutes to realize the dispersion of the material in the circulation pump, then stop 5 minutes is to prevent the heat generated during the stirring process from causing the temperature inside the circulation pump to rise, thus causing the oil in the vegetable sludge to oxidize and deteriorate under high temperature co...

Embodiment 3

[0043] A kind of process of extracting and pressing method processing vegetable oil sludge, such as figure 1 with figure 2 shown, including the following steps:

[0044] S1. Extraction: Pour the vegetable sludge into the extraction tank, and add the extractant to the extraction tank (the mass percentage of the extractant and the vegetable sludge is 1:10), and then the mixture of the vegetable sludge and the extractant enters the circulating pump Dispersion, control the temperature in the circulation pump by means of water bath heating and keep it at 35°C and the impeller speed of the circulation pump is 2000 rpm; first start the circulation pump and run forward for 10 minutes to realize the dispersion of the material in the circulation pump, then stop 5 minutes is to prevent the heat generated during the stirring process from causing the temperature inside the circulation pump to rise, thus causing the oil in the vegetable sludge to oxidize and deteriorate under high tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com