High-chambering hot-rolled pickled steel plate with yield strength of 550 MPa

A yield strength, hot-rolled pickling technology, applied to heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of mismatching stamping performance and hole expansion performance, and can not meet the load-carrying and formability problems, to achieve excellent stamping Performance and hole expansion performance, low alloy cost, effect of low alloy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

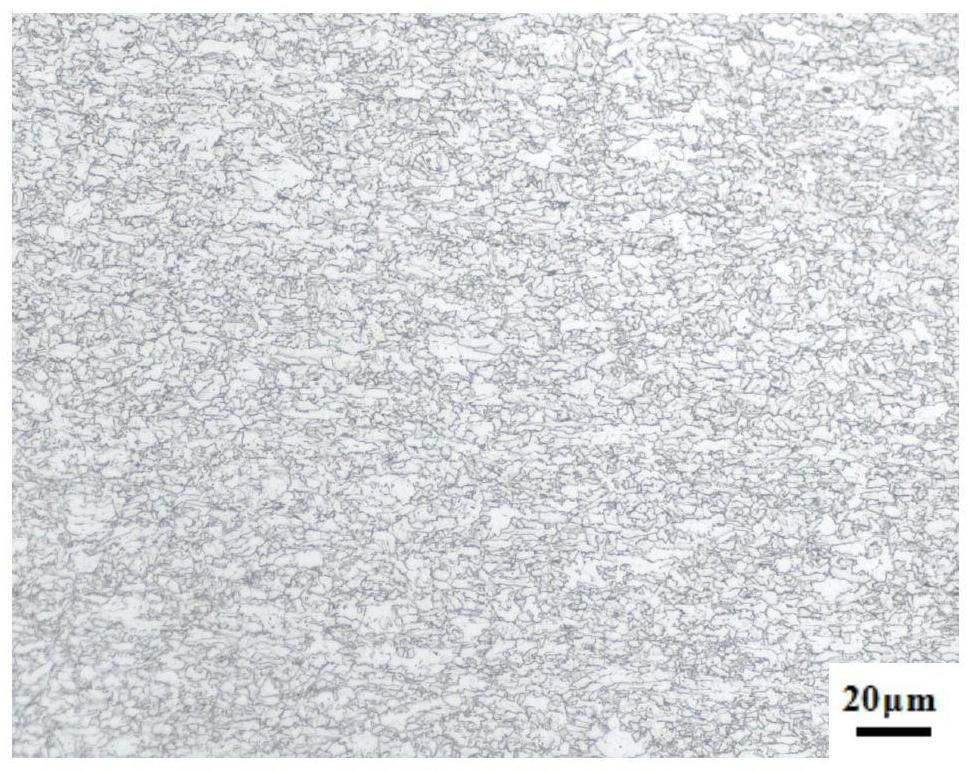

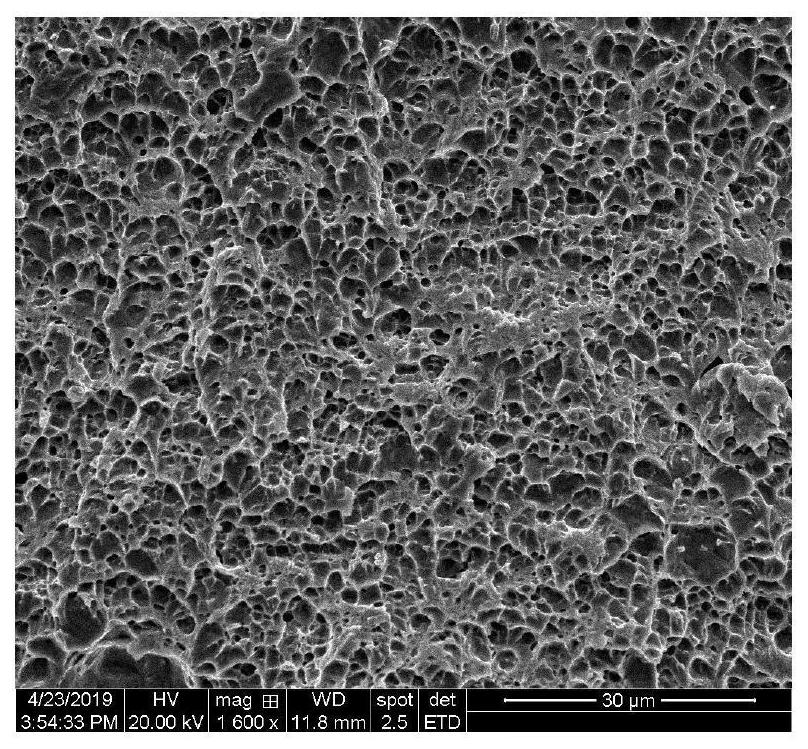

Image

Examples

Embodiment Construction

[0047]The present invention will be further described below in conjunction with Examples 1 to 5, as shown in Tables 1 to 5, it will be understood that the following specific embodiments are intended to illustrate only the invention and are not intended to limit the scope of the invention.

[0048]Table 1 is a chemical component (by weight percent) of the embodiment of the present invention, the margin is Fe and inevitable impurities.

[0049]Table 1 The chemical composition of the steel of the present invention, unit: weight percent.

[0050]

[0051]Through the converter smelting steel water, the steel water is blown by the LF steel bag refining furnace refining process, and the steel water is blown through the whole process to obtain a continuous casting slab; the thickness of the continuous casting slab is 210 ~ 230 mm, the width is 800 ~ 1300mm, length is 5000 ~ 10000mm.

[0052]The fixed sheets produced by steelmaking are sent to the heating furnace and then heat it, and the phosphorus is rel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com