Method for preparing zirconium-based amorphous/nanocrystalline composite coating on surface of zirconium alloy

A nanocrystalline composite and zirconium-based amorphous technology, which is applied in the coating process of metal materials, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]First dry the zirconium powder with a particle size of 200 mesh in a vacuum environment at 50°C for 12 hours, then weigh 75.87g of Zr powder, 11.37g of Ni powder, 3.79g of Al powder, and 8.94g of Cu powder with a particle size of 200 mesh, and put various powder materials in a QM-3SP4 planetary ball mill Mix well, ball milling speed is 500r / min, ball milling time is 2h, vacuum drying is 2h, temperature is 50°C, and natural cooling is performed to obtain mixed powder for laser cladding. In the cladding powder, the particle size of the Zr powder, Al powder, Ni powder and Cu powder is 100-200 mesh, and the purity is 99.5%.

[0031] Take a 702 zirconium block sample with a size of 20×20×10mm, rough-grind the surface with 180-mesh metallographic sandpaper, wash it with acetone to remove oil, wipe it clean, wipe it with alcohol, and blow it dry to obtain pretreatment zirconium alloy matrix material.

[0032] The surface-treated zirconium alloy samples were placed on the laser...

Embodiment 2

[0041] Taking the matrix and powder in Example 1, adjust the laser cladding process parameters as follows: laser power 1600W, spot diameter 4mm, scanning speed 5mm / s. Under laser energy irradiation, a coating that is metallurgically bonded to the substrate is formed on the surface of the zirconium alloy.

[0042] Laser remelting treatment is performed on the coating after cladding, and the laser remelting process parameters are the same as those in Example 1.

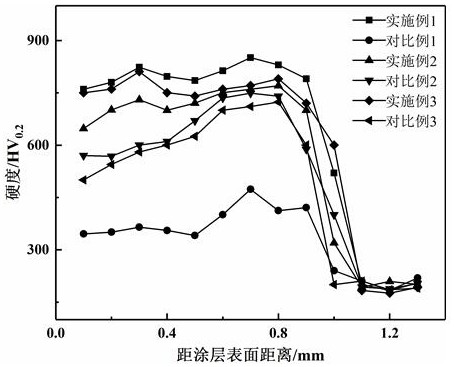

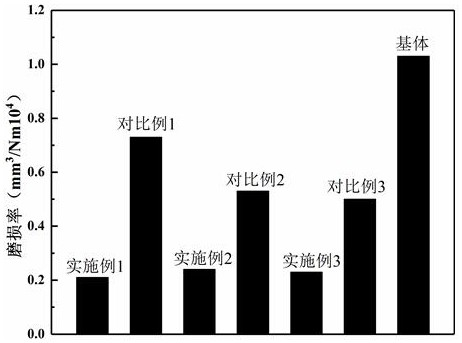

[0043] According to the test method of Example 1, the hardness and wear resistance of the cladding layer were detected. Hardness curve such as figure 1 As shown, the wear rate results are as figure 2 shown.

experiment example 3

[0049] Take the matrix and powder in Example 1, and use the laser cladding process parameters in Example 1 to carry out cladding. Under laser energy irradiation, a coating that is metallurgically bonded to the substrate is formed on the surface of the zirconium alloy.

[0050] Perform laser remelting treatment on the coating after cladding: laser power 1500W, spot diameter 4mm, scanning speed 12mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com