A temperature-adjusting antibacterial anti-mosquito yarn, fabric and preparation method thereof

A kind of anti-mosquito fabric and anti-mosquito technology, applied in the direction of fabric, fabric surface trimming, heating/cooling fabric, etc., can solve the problems of temperature adjustment, antibacterial and deodorization, anti-mosquito, etc. Long-lasting effect, prolonging the use period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

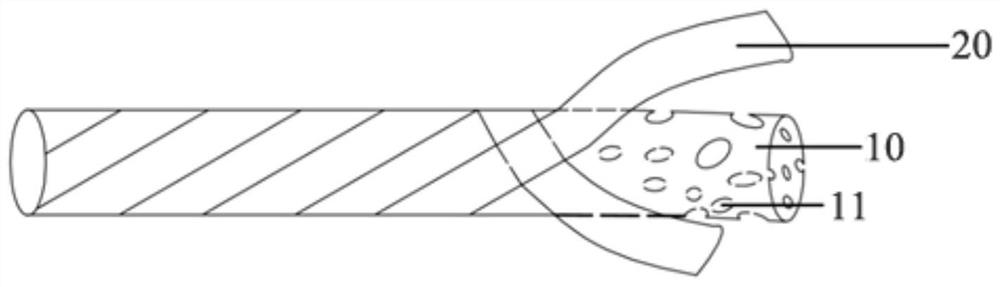

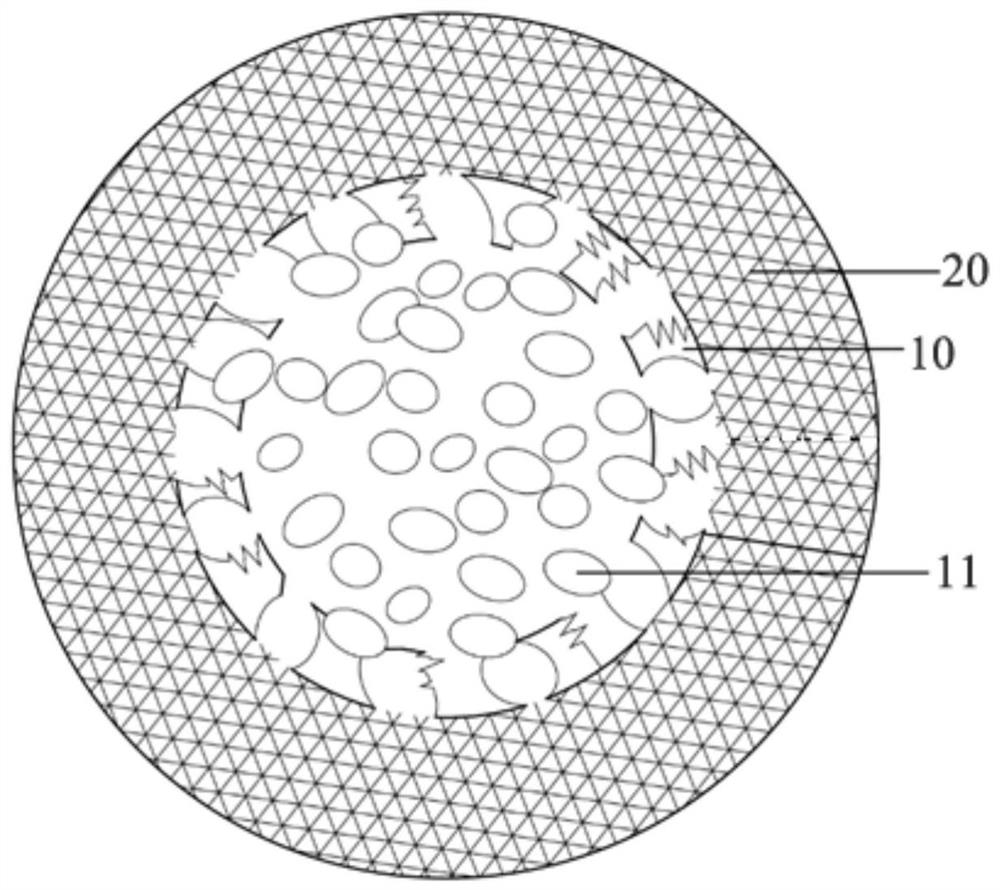

Image

Examples

preparation example Construction

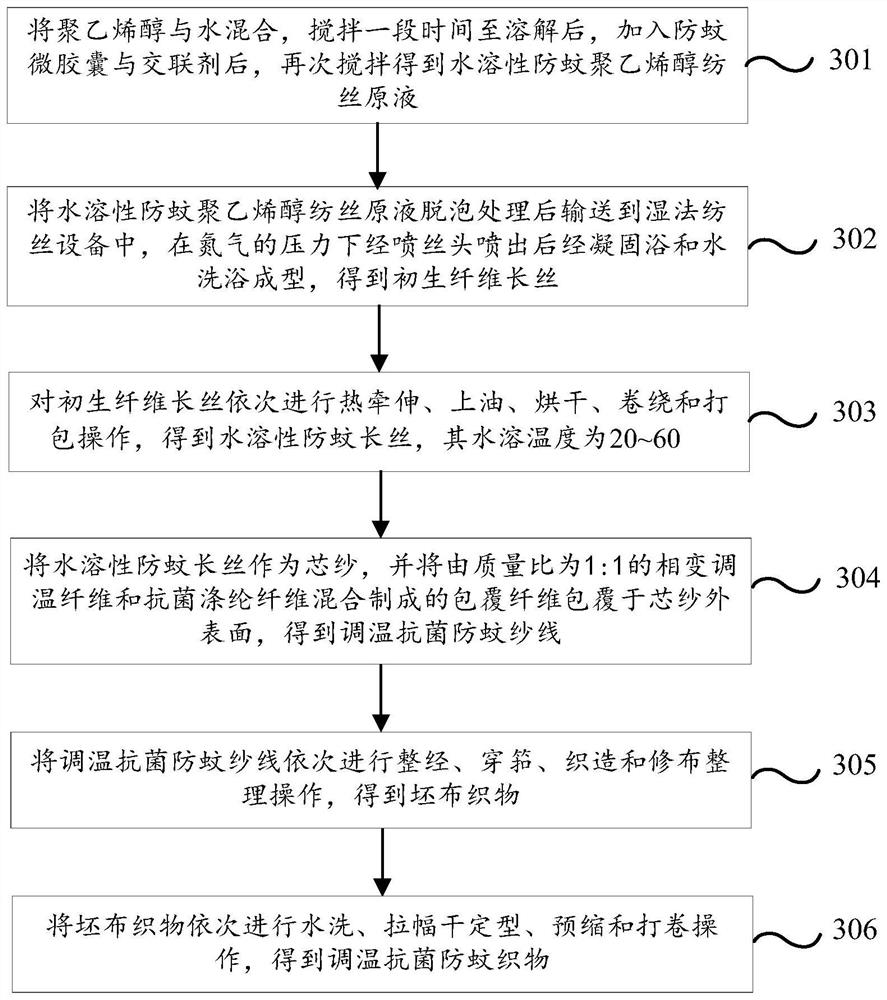

[0067] refer to image 3 As shown, based on the same inventive concept, the embodiment of the present invention provides a preparation method of a temperature-regulating antibacterial and mosquito repellent fabric, and the method mainly includes the following steps:

[0068] 301. Mix the polyvinyl alcohol with water, stir for a period of time until dissolved, add the mosquito-proof microcapsules and the cross-linking agent, and stir again to obtain the water-soluble mosquito-proof polyvinyl alcohol spinning stock solution.

[0069] In this step, after weighing the raw materials according to the required mass percentage, the weighed polyvinyl alcohol and water are placed in the reaction kettle to be mixed and reacted, and stirred for a period of time until the polyvinyl alcohol is completely dissolved, and then the weighed polyvinyl alcohol is added. The obtained anti-mosquito microcapsules and cross-linking agent are stirred again to obtain a water-soluble anti-mosquito polyvi...

Embodiment 1

[0108] (1) Weigh the raw materials according to the mass percentage: 14% of polyvinyl alcohol with a degree of polymerization of 1200 and a degree of alcoholysis of 60%, 10% of anti-mosquito microcapsules, 1% of a cross-linking agent, and the balance is water, the cross-linking agent Use carbonamide;

[0109] The weighed polyvinyl alcohol and water are placed in the reaction kettle to be mixed and reacted. The reaction temperature is 80 ° C. After stirring for 3 hours at a stirring speed of 200 rev / min, the weighed anti-mosquito microcapsules and the cross-talk are added. The water-soluble anti-mosquito polyvinyl alcohol spinning stock solution is obtained after stirring for 0.5 hours.

[0110] (2) The water-soluble anti-mosquito polyvinyl alcohol spinning stock solution is defoamed and filtered, and then transported to the wet spinning equipment. It is ejected through a spinneret with a diameter of 0.05mm, and then is formed through a coagulation bath and a water bath to obt...

Embodiment 2

[0116] (1) Weigh the raw materials according to the mass percentage: 16% of polyvinyl alcohol with a degree of polymerization of 1600 and a degree of alcoholysis of 70%, 10% of anti-mosquito microcapsules, 2% of cross-linking agent, and the balance of water, the cross-linking agent Use carbonamide;

[0117] The weighed polyvinyl alcohol and water are placed in the reaction kettle to be mixed and reacted. The reaction temperature is 85 ° C. After stirring for 4 hours at a stirring speed of 300 rev / min, the weighed anti-mosquito microcapsules and the cross-talk are added. The water-soluble anti-mosquito polyvinyl alcohol spinning stock solution is obtained after stirring for 0.5 hours.

[0118] (2) The water-soluble anti-mosquito polyvinyl alcohol spinning stock solution is defoamed and filtered, and then transported to the wet spinning equipment. It is ejected through a spinneret with a diameter of 0.08 mm, and then is formed by a coagulation bath and a water bath to obtain pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com