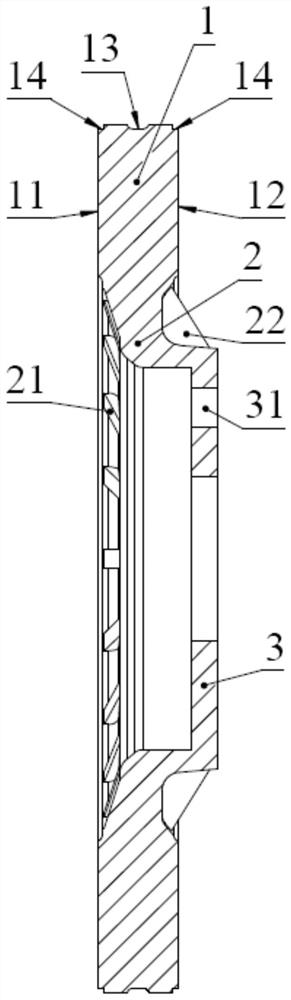

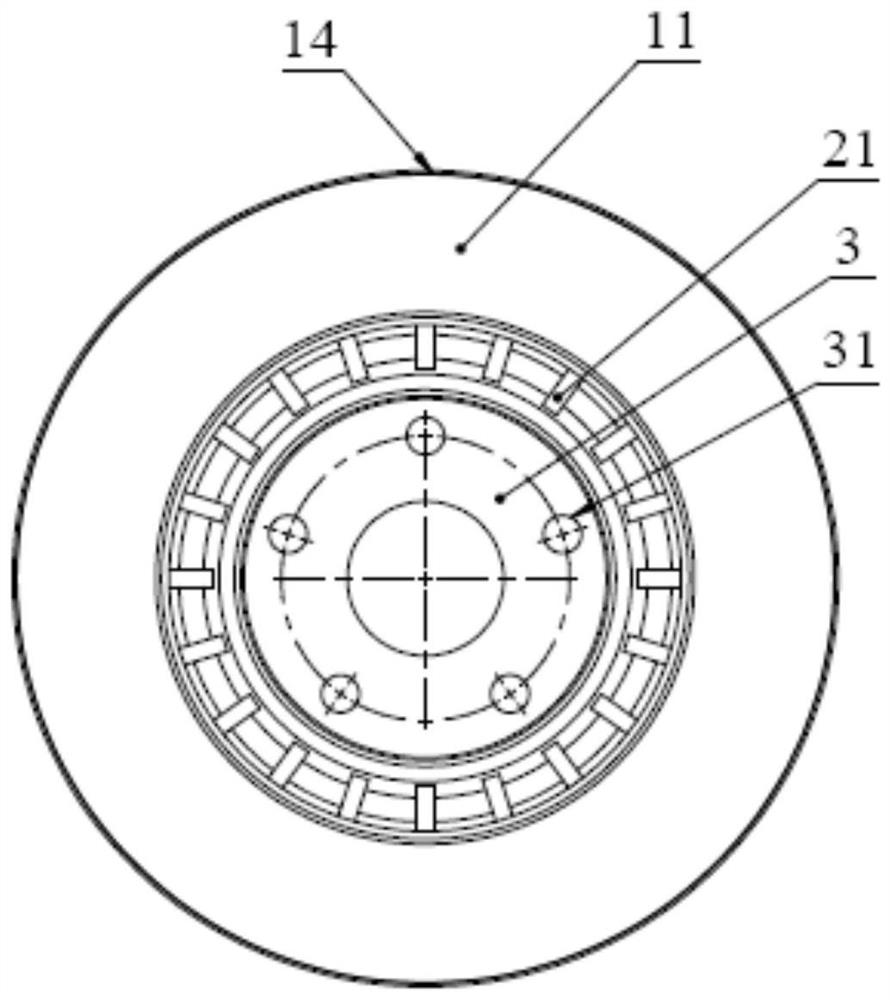

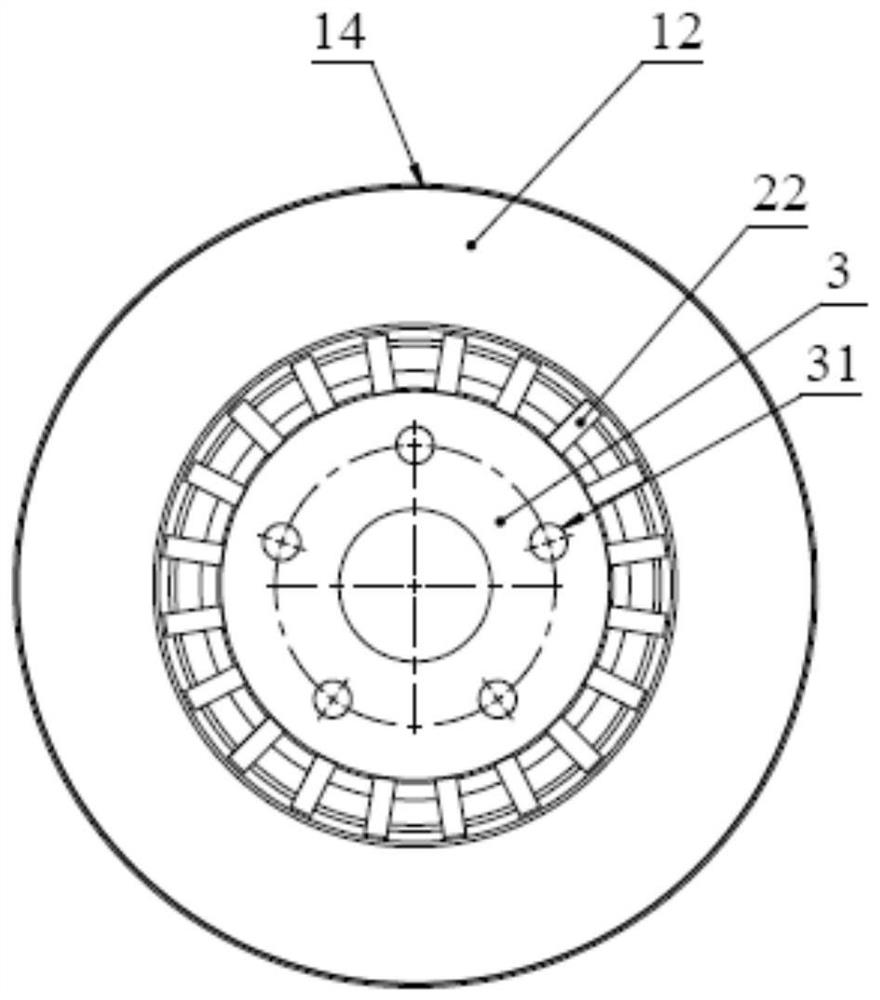

Aluminum-based composite solid brake disc for automobile and preparation method of aluminum-based composite solid brake disc

A technology of aluminum-based composite materials and brake discs, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems of reduced braking performance and poor heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] In one embodiment, a method for preparing a solid brake disc of an aluminum matrix composite material for automobiles provided by the present invention comprises the following steps:

[0061] S1: Heat the A356 aluminum alloy in the crucible to 680-750°C, for example, you can choose 680°C, 690°C, 700°C, 730°C or 750°C, after refining and degassing, cool down to 650°C with the furnace, in nitrogen or argon Or keep warm under vacuum protection for use;

[0062] S2: adding 18-28wt% SiC to the A356 aluminum alloy melt obtained in step S1, and stirring evenly;

[0063] S3: Heating the mixture of aluminum alloy and SiC obtained in step S2 to 680-750°C, for example, 680°C, 690°C, 700°C, 730°C or 750°C, for anti-gravity casting to obtain the casting blank of the brake disc .

[0064] S4: Machining the casting blank obtained in step S3 to obtain a solid brake disc of aluminum matrix composite material for automobiles.

[0065] In an optional embodiment, in the above step S3, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com