Vacuum precooling preservation technology for leaf vegetables harvested in high-temperature seasons

A vacuum and high temperature technology, which is applied in the direction of fruit and vegetable preservation, food ingredients as antimicrobial preservation, food preservation, etc., to delay the aging process, remove free radicals, and solve the effects of water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

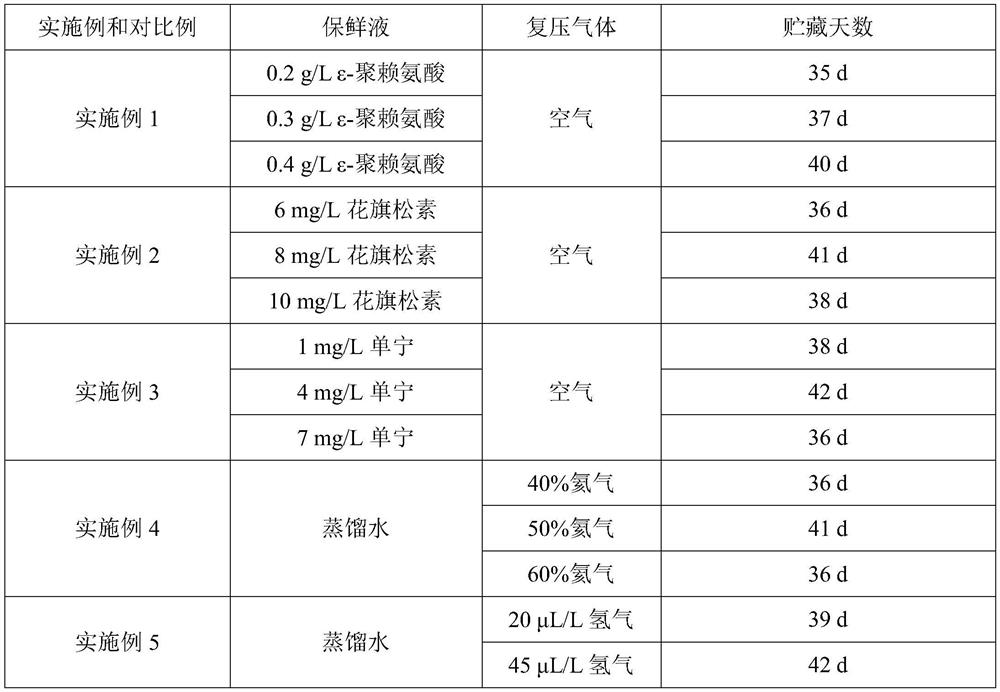

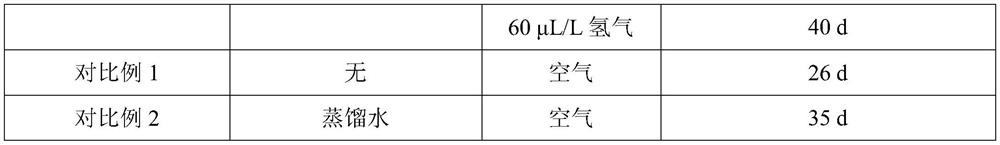

Embodiment 1

[0030] This embodiment provides a vacuum pre-cooling and fresh-keeping technology for harvesting leafy vegetables in high-temperature seasons. Harvesting Shanghai greens with bright color, no yellow leaves and diseases from the field, put them in baskets in a vacuum pre-cooling room, and insert them in the center of the cabbage. For the temperature sensor, set the final pre-cooling temperature to 6°C. Start pre-cooling, when the temperature drops to 6°C, the pressure is constant at 800-900pa, start the atomization system equipped with ε-polylysine (0.2, 0.3 and 0.4g / L) solution, and stop the fog after 5min Afterwards, air was introduced to restore the pressure to 1 standard atmosphere. After the pre-cooling is over, the time is about 30-40 minutes. Take out the Shanghai Greens and place them in baskets, and store them at low temperature (0-5°C).

Embodiment 2

[0032] The atomization system is equipped with Taxifolin (6, 8 and 10 mg / L) solution, and other methods are the same as in Example 1.

Embodiment 3

[0034] The atomization system is equipped with tannin (1, 4 and 7 mg / L) solutions, and other methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com