Double-layer beef tallow hotpot condiment and processing method thereof

A technology of hot pot bottom material and butter, which is applied in the field of food processing, can solve the problems of incomplete nutrition, inability to meet diversified market demands, and single taste, so as to alleviate the stimulation of spicy taste, improve the quality of soup juice, and slow down the dissolution time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

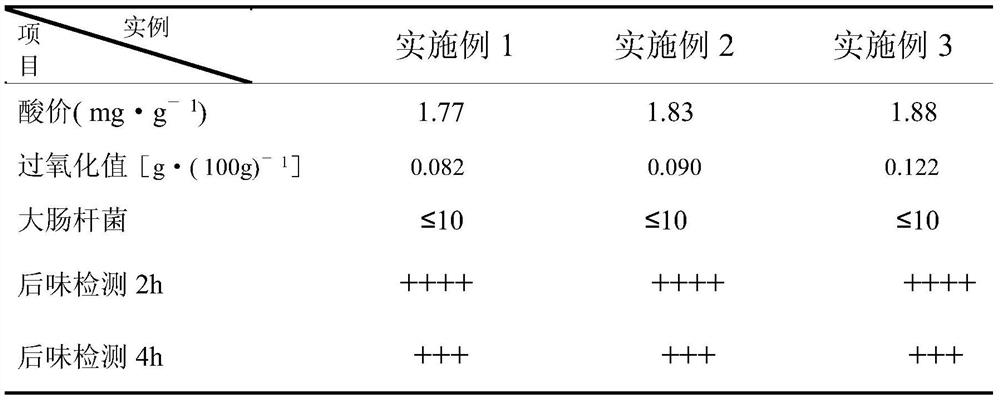

Examples

preparation example Construction

[0080] A preparation method for double-layer butter hot pot bottom material, comprising the following steps:

[0081] Step 1: Cut the onion into pieces with a side length not greater than 20 mm, immerse the onion and salad oil in the salad oil at a ratio of 1:5 by weight, and place it at room temperature for 72 hours to obtain the onion salad oil;

[0082] Step 2: heating butter to 140-160°C and adding it to onion salad oil and chicken oil to obtain the first intermediate product;

[0083] Step 3: Heat the first intermediate product to 150°C, put in dried chili, baby’s breath and Chinese prickly ash and fry till fragrant to obtain the second intermediate product;

[0084] Step 4: Add bean paste and tempeh to the second intermediate product and fry for 3-7 minutes until the temperature is 100-120°C to obtain the third intermediate product;

[0085] Step 5: add garlic and rock sugar to the third intermediate product and fry for 10-20 minutes, and the frying temperature reaches ...

Embodiment 1

[0094] A preparation method for a double-layer butter hot pot bottom material, comprising the following steps, characterized in that: it includes an integrated inner core layer and an outer layer, and the integrated inner core layer and outer layer all include the following ingredients: refined butter , onion salad oil, chicken oil, spices to make white wine, fermented soybeans.

[0095] The components in parts by weight, the inner core layer includes: 150 parts of refined butter, 50 parts of onion salad oil, 35 parts of chicken oil, 3 parts of white wine brewed with spices, 30 parts of tempeh, 40 parts of tapioca starch, hawthorn 18 parts, 18 parts of red date slices, 8 parts of ginger skin, 5 parts of lemon juice, 0.5 parts of edible gelatin;

[0096] The components by weight, the outer layer includes: 300 parts of refined butter, 100 parts of onion salad oil, 70 parts of chicken oil, 10 parts of white wine brewed with spices, 30 parts of tempeh, 60 parts of dried chili, ful...

Embodiment 2

[0109] A preparation method for a double-layer butter hot pot bottom material, comprising the following steps, characterized in that: it includes an integrated inner core layer and an outer layer, and the integrated inner core layer and outer layer all include the following ingredients: refined butter , onion salad oil, chicken oil, spices to make white wine, fermented soybeans.

[0110] The components in parts by weight, the inner core layer includes: 180 parts of refined butter, 60 parts of onion salad oil, 40 parts of chicken oil, 4 parts of white wine brewed with spices, 45 parts of tempeh, 50 parts of tapioca starch, hawthorn 25 parts, 25 parts of red date slices, 10 parts of ginger skin, 10 parts of lemon juice, 0.7 parts of edible gelatin;

[0111] The components by weight, the outer layer includes: 360 parts of refined butter, 120 parts of onion salad oil, 80 parts of chicken oil, 18 parts of white wine brewed with spices, 50 parts of tempeh, 65 parts of dried chili, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com