Breathable mask and manufacturing method thereof

A technology of air permeability and masks, which is applied in the field of masks, can solve the problems of large vibration and noise of mud tank trucks, and achieve high retention rate, resource saving, and excellent air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

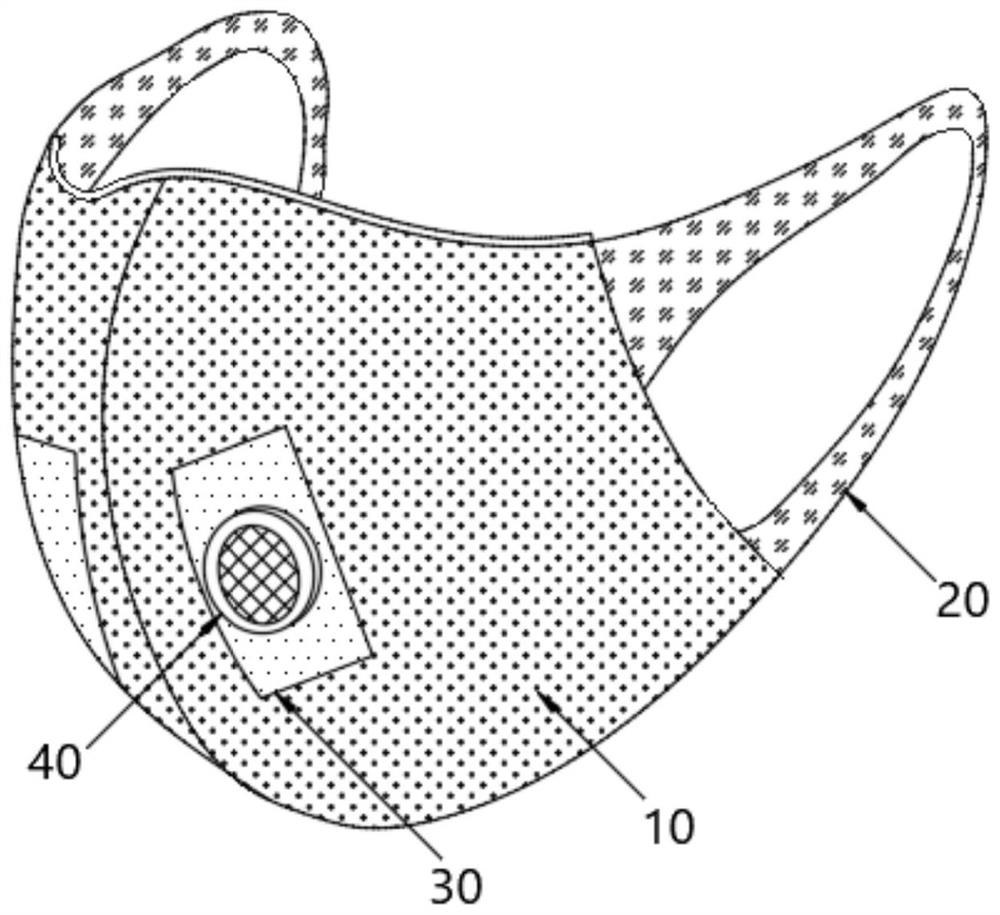

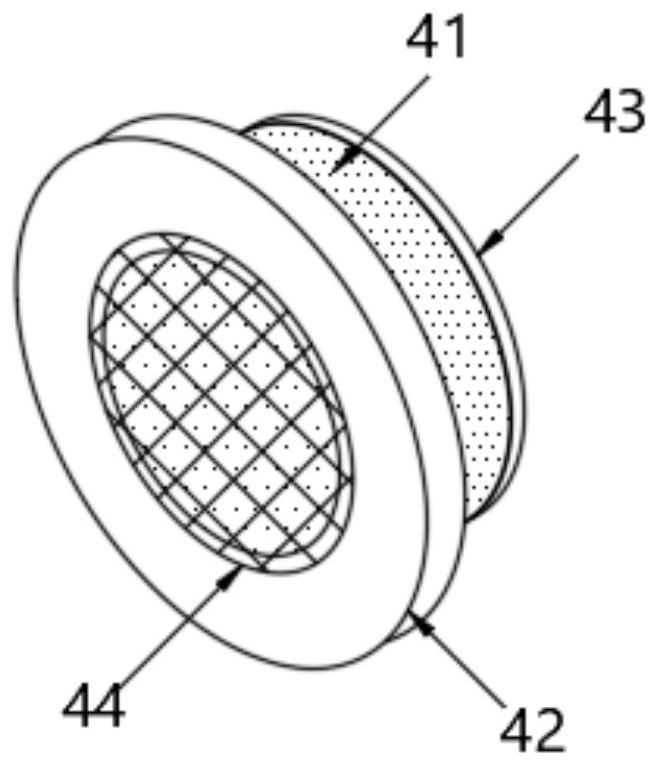

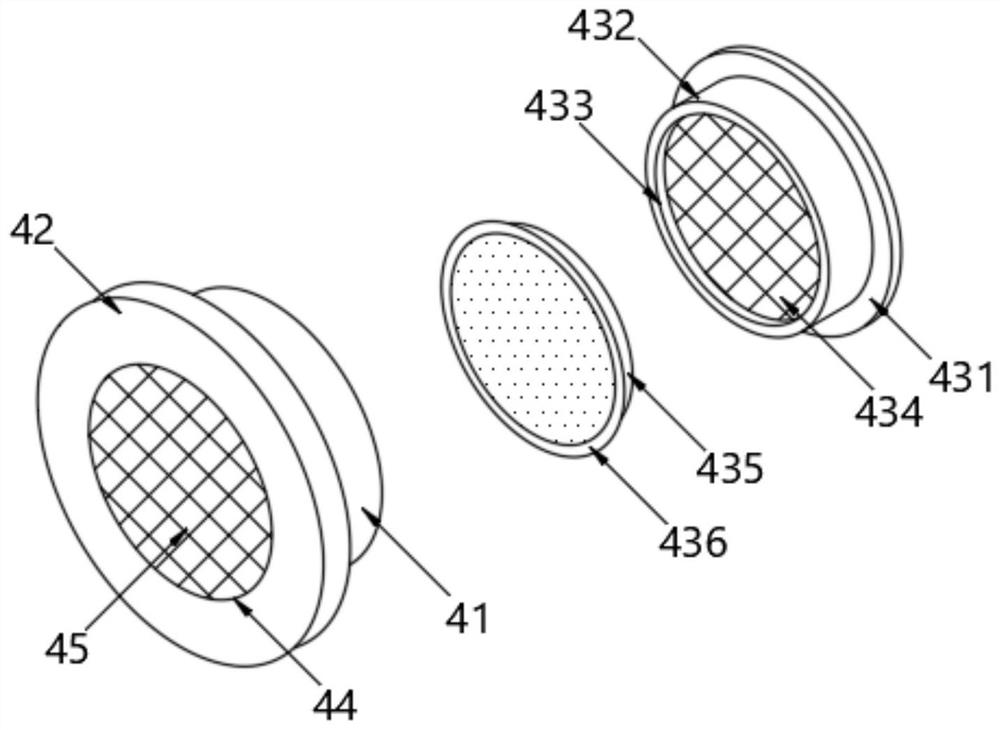

[0034] A breathable mask, such as Figure 1-Figure 3 As shown, the mask body 10 and the ear straps 20 symmetrically arranged on both sides of the mask body 10 are included. The mask body 10 is provided with some evenly spaced ventilating parts 30, and each ventilating part 30 is equipped with a detachable air-permeable filter. Structure 40, the detachable air-permeable filter structure 40 includes a plug-in joint 41 that is plugged and fitted with the air-permeable part 30, and one end of the plug-in joint 41 is coaxially connected with a limit seat 42, and a coaxial spacer is provided on the plug joint 41 and the limit seat 42. Vent hole 44, the end of plug joint 41 away from limit seat 42 is plugged with pressing device 43, and pressing device 43 comprises the pressing head 432 that inserts with vent hole 44, and one end of pressing head 432 is equipped with seal ring 431, presses The head 432 and the sealing ring 431 are provided with a coaxial air vent 433, and an end of t...

Embodiment 2

[0045] As a second embodiment of the present invention, the air-permeable filter element 435 is made of antibacterial filter material.

[0046] Further, the antibacterial filter material is a composite film of polymer nanofiber and support body non-woven fabric, wherein, the thickness of the polymer nanofiber film layer containing antibacterial agent is 5-15um, and the diameter of the polymer nanofiber in the film layer 500-700nm.

[0047] Specifically, the antibacterial filter material is made of antibacterial agent, polymer nanofiber and support body non-woven fabric, and the weight ratio of antibacterial agent, polymer nanofiber and support body non-woven fabric is 2-10:15-25:80- 90.

[0048] It is worth noting that the polymer nanofiber is one of polyethersulfone or polyvinylidene fluoride.

[0049] In the air-permeable mask of the present embodiment, the air-permeable filter core 435 is made of antibacterial filter material, which not only has excellent air permeability...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com