Integrated device for preparing, separating and purifying silyl enol ether

An enol silyl ether and reactor technology, which is applied in the field of integrated devices for the preparation, separation and purification of enol silyl ether, can solve the problems of pollution and toxicity, loss of enol silyl ether products, and harm to the health of experimenters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

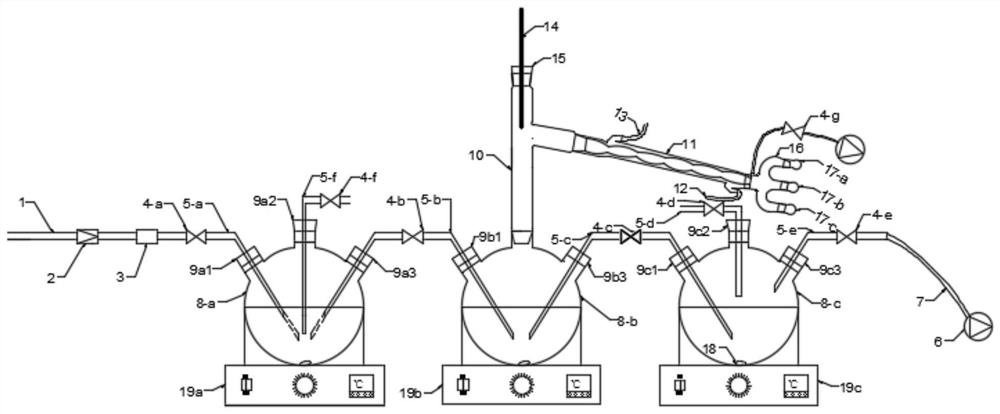

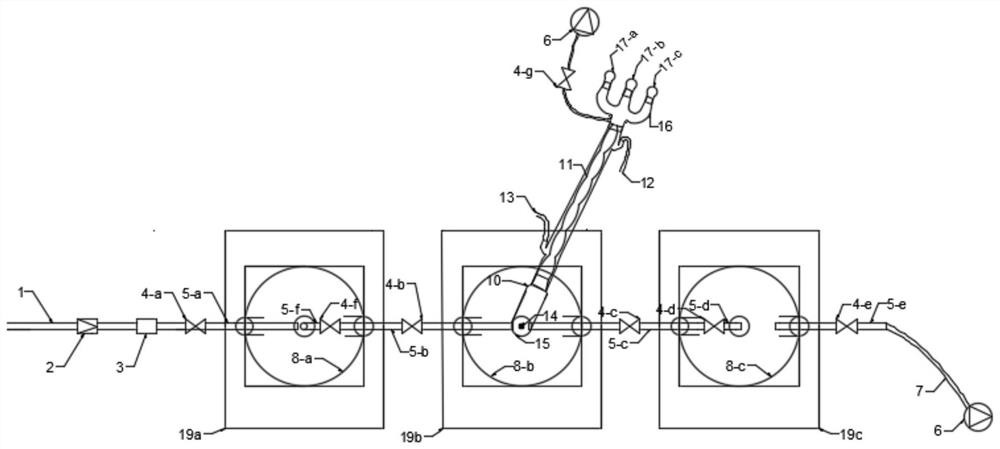

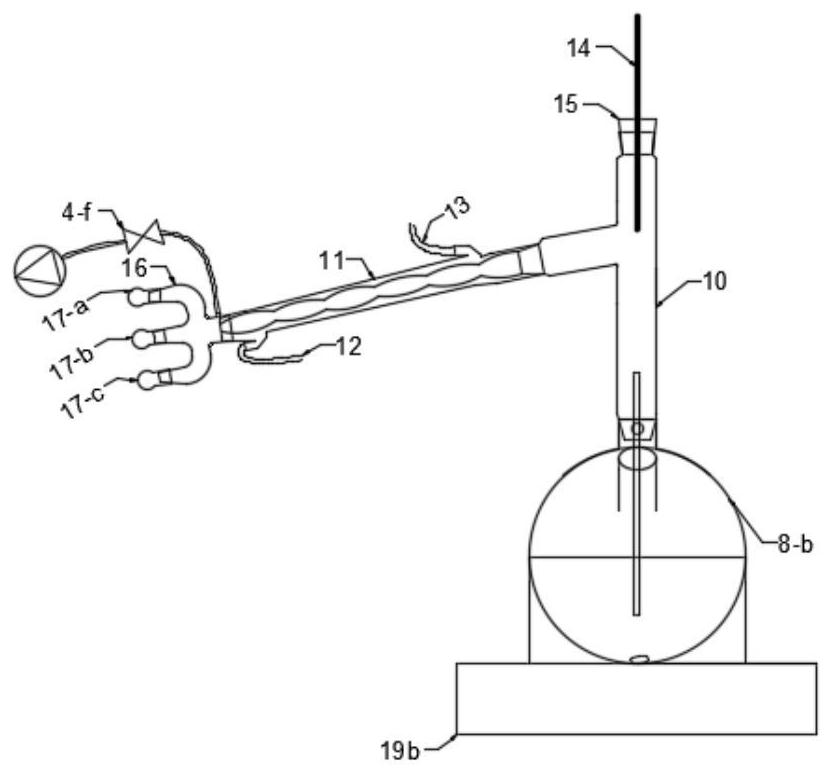

[0055] figure 1 It is a structural schematic diagram of an integrated device for the preparation, separation and purification of enol silyl ethers of the present invention. figure 2 , image 3 Schematic diagrams of the device position from top view and side view, respectively. Such as figure 1 As shown, an integrated device for the preparation, separation and purification of enol siloxanes of the present invention includes an intake pipeline 1, a pressure reducing valve 2, a mass flow meter 3, a first stop valve 4-a, a first Second stop valve 4-b, third stop valve 4-c, fourth stop valve 4-d, fifth stop valve 4-e, sixth stop valve 4-f, seventh stop valve 4-g, first glass Tube 5-a, second glass tube 5-b, third glass tube 5-c, fourth glass tube 5-d, fifth glass tube 5-e, sixth glass tube 5-f, pump 6, pumping Rubber tube 7, the first round bottom flask 8-a, the second round bottom flask 8-b, the third round bottom flask 8-c, the first ground glass stopper with holes 9a1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com