Recycling and preparing system for negative electrode materials of lithium titanate batteries through waste lithium titanate batteries

A technology of lithium titanate battery and negative electrode material, which is applied in the direction of battery recycling, waste collector recycling, recycling technology, etc., can solve the problems that the safety of the discharge process needs to be improved, it is inconvenient to classify and discharge lithium batteries, etc., to ensure dismantling. Safety, Assured Positioning and Advance Control, Assurance of Stability Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

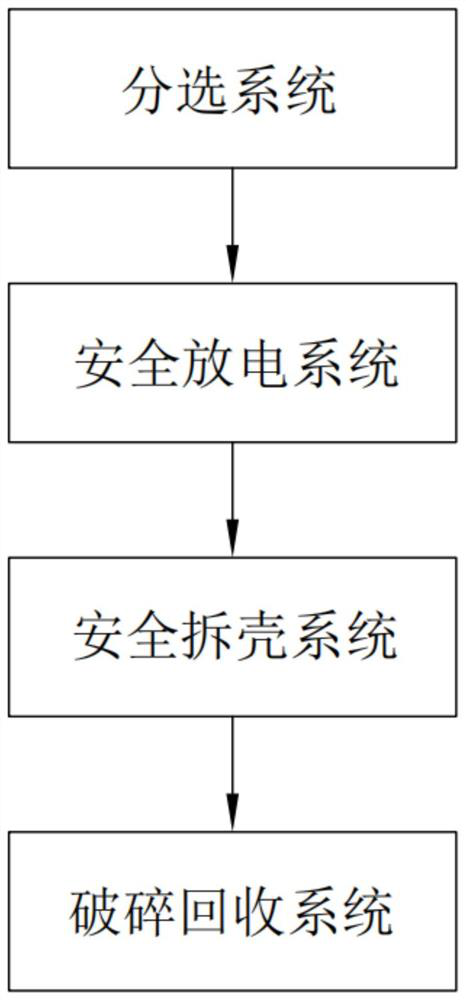

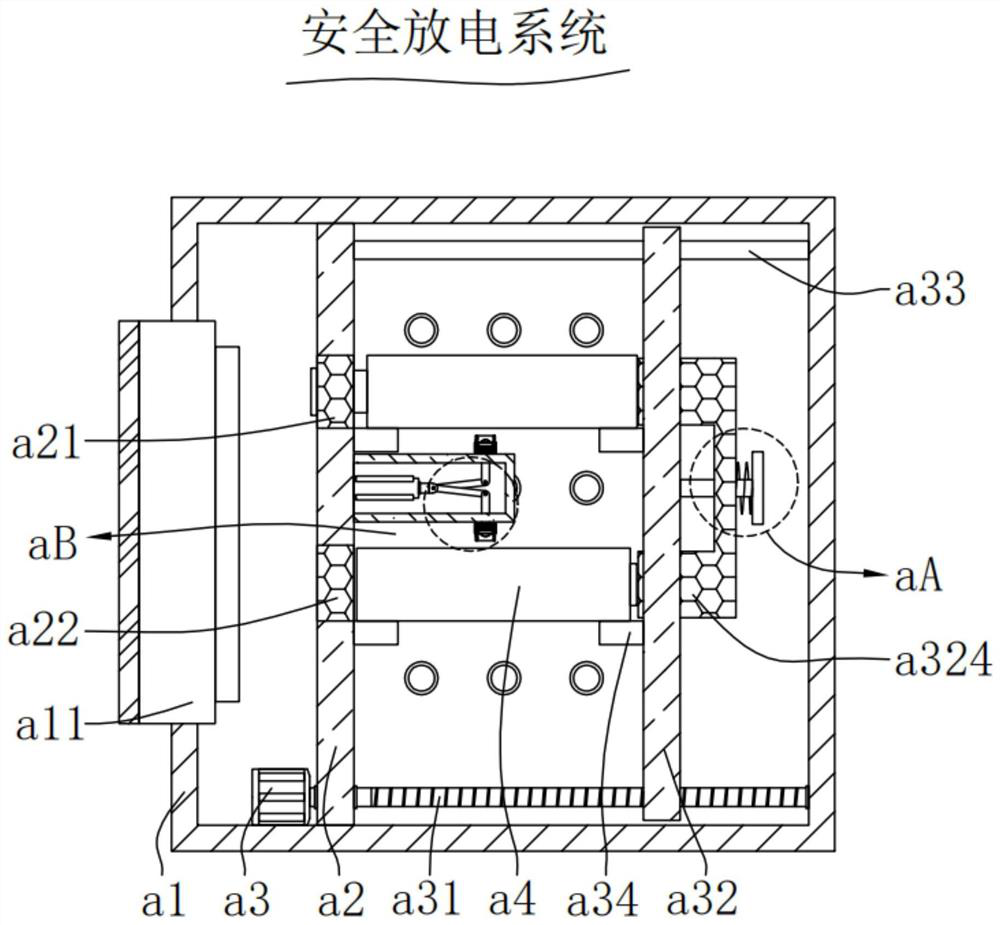

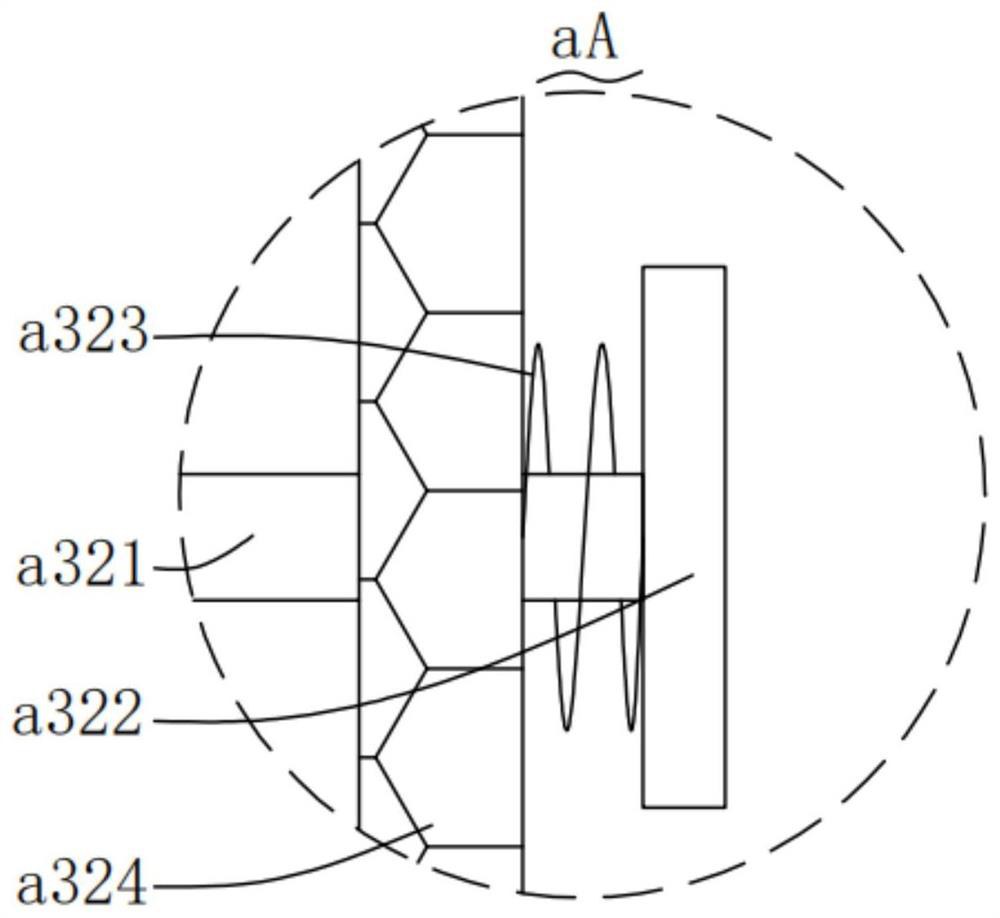

[0034] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 with Figure 12 ,in, figure 1 A system block diagram of a preferred embodiment of the lithium titanate battery negative electrode material provided by the present invention through the recovery and preparation system of waste lithium titanate batteries; figure 2 for figure 1 The schematic diagram of the structure of the safety discharge system shown; image 3 for figure 2 The enlarged schematic diagram of part aA shown; Figure 4 for figure 2 The enlarged schematic diagram of part aB shown; Figure 5 for Figure 4 The enlarged schematic diagram of part aC shown; Image 6 for figure 2 The schematic diagram of the structure of the heat pipe shown; Figure 7 The circuit diagram of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com