Preparation method of group-regulated high-density graphene heat-conducting film and obtained product

A high-density, graphene technology, applied in the field of graphene, can solve the problems of poor film performance, low density of low-solid slurry, high viscosity of high-solid slurry, etc., to achieve uniform density, large coating density, Excellent surface condition and homogeneous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

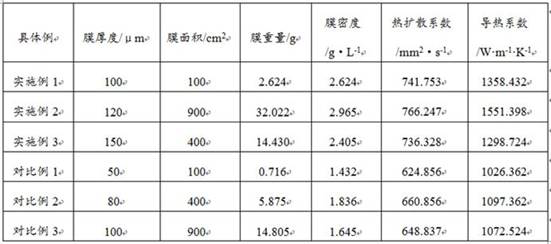

Examples

Embodiment 1

[0034] A method for preparing a high-density graphene heat conduction film regulated by groups, comprising the following steps:

[0035] Add 0.1% hydrochloric acid to 10 g of deionized water, and use a high-speed mixer to stir and disperse to obtain the first slurry;

[0036] Weigh the graphene oxide filter cake according to the solid content of the first slurry of 5%, use a blade mill to granulate it into 1mm particles, and then add it to the above first slurry, first stir at 300rpm for 15min, then stir at 1000rpm Stir at a high speed for 30 minutes to obtain a hydrophobic high-solid slurry;

[0037] Use an ultrasonic homogenizer to perform ultrasonic homogenization treatment on the obtained hydrophobic high solid content slurry, the frequency is 20kHz, and the sound intensity is 1W / cm 2 , to obtain a uniformly dispersed second slurry;

[0038] Use a double planetary mixer to disperse and stir the second slurry, add ammonia water with a mass of 0.1% of the slurry to it, and...

Embodiment 2

[0044] A method for preparing a high-density graphene heat conduction film regulated by groups, comprising the following steps:

[0045] 10% hydrochloric acid was added to 10kg deionized water, and a high-speed mixer was used to stir and disperse to obtain the first slurry;

[0046] Weigh the graphene oxide filter cake according to the solid content of the first slurry of 5%, use a blade mill to granulate it into 1cm particles, and then add it to the above first slurry, first stir at 600rpm for 5min, then stir at 1500rpm Stir at a high speed for 15 minutes to obtain a hydrophobic high-solid slurry;

[0047] Use an ultrasonic homogenizer to perform ultrasonic homogenization treatment on the obtained hydrophobic high solid content slurry, the frequency is 300kHz, and the sound intensity is 20W / cm 2 , to obtain a uniformly dispersed second slurry;

[0048] Use a double planetary mixer to disperse and stir the second slurry, add ammonia water with a mass of 10% of the slurry to ...

Embodiment 3

[0054] A method for preparing a high-density graphene heat conduction film regulated by groups, comprising the following steps:

[0055] 3% hydrochloric acid was added to 1 kg of deionized water, and a high-speed mixer was used to stir and disperse to obtain the first slurry;

[0056] Weigh the graphene oxide filter cake according to the solid content of the first slurry of 3%, use a blade mill to granulate it into 4mm particles, and then add it to the above-mentioned first slurry, first stir at 400rpm for 8min, then stir at 1200rpm Stir at a high speed for 20 minutes to obtain a hydrophobic high-solid slurry;

[0057] Use an ultrasonic homogenizer to perform ultrasonic homogenization treatment on the obtained hydrophobic high solid content slurry, the frequency is 100kHz, and the sound intensity is 10W / cm 2 , to obtain a uniformly dispersed second slurry;

[0058] Use a double planetary mixer to disperse and stir the second slurry, add ammonia water with a mass of 4% of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com