Method for simultaneously preparing calcium sulfate, potassium nitrate, potassium magnesium nitrate and magnesium carbonate from calcium magnesium ammonium nitrate liquid

A technology of ammonium, calcium and magnesium nitrate and potassium and magnesium nitrate is applied in the field of chemical industry, and can solve the problems of effective utilization of magnesium and calcium separated elements, and achieve the effect of improving the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

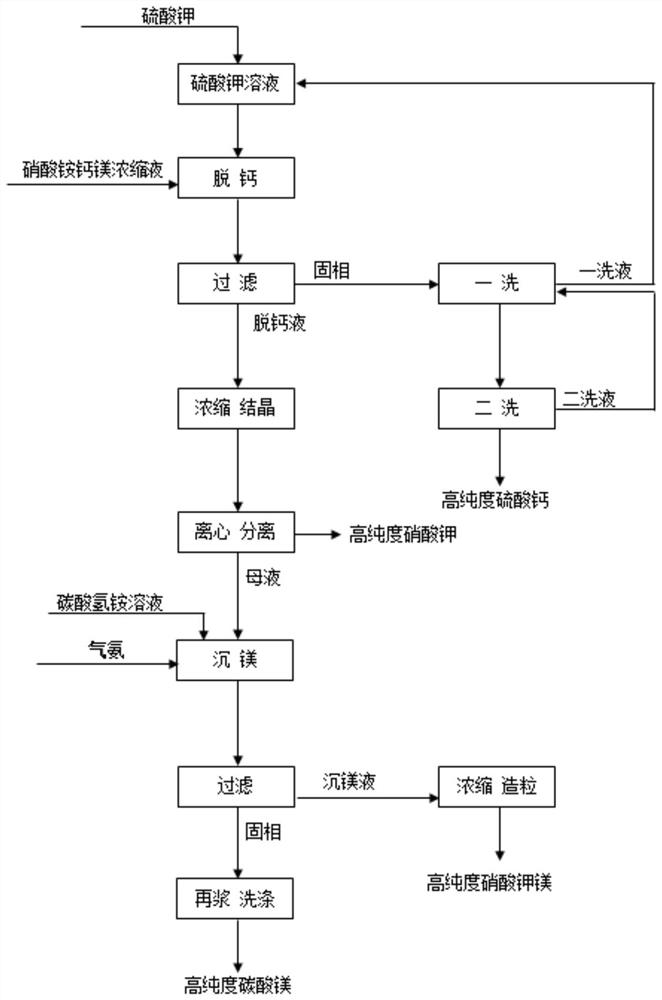

Image

Examples

Embodiment 1

[0061] Present embodiment proposes a kind of ammonium nitrate calcium magnesium solution and prepares the method for calcium sulfate, potassium nitrate, potassium magnesium nitrate and magnesium carbonate simultaneously, comprises the following steps:

[0062] The potassium sulfate solution with a concentration of 20wt% and the ammonium nitrate calcium magnesium solution with a concentration of 25wt% are in a mass ratio of 1:1, and the decalcification reaction is carried out at 80° C. for 4 hours, and filtered in a filter to obtain the decalcification solution and potassium sulfate.

[0063] Wash (one wash) the potassium sulfate after the above-mentioned filtration with water for the first time, and the lotion (one lotion) after one wash is used as the solvent of the next batch of calcium sulfate, and the solid phase is carried out with water for the second time after one wash. Washing (secondary washing), the washing liquid after the second washing (secondary washing liquid) i...

Embodiment 2

[0069] Present embodiment proposes a kind of ammonium nitrate calcium magnesium solution and prepares the method for calcium sulfate, potassium nitrate, potassium magnesium nitrate and magnesium carbonate simultaneously, comprises the following steps:

[0070] The potassium sulfate solution with a concentration of 35wt% and the ammonium nitrate calcium magnesium solution with a concentration of 28wt% are in a mass ratio of 3:5, and the decalcification reaction is carried out at 110° C. for 3 hours, and filtered in a filter to obtain the decalcification solution and potassium sulfate.

[0071] Wash (one wash) the potassium sulfate after the above-mentioned filtration with water for the first time, and the lotion (one lotion) after one wash is used as the solvent of the next batch of calcium sulfate, and the solid phase is carried out with water for the second time after one wash. Washing (secondary washing), the washing liquid after the second washing (secondary washing liquid) ...

Embodiment 3

[0077] Present embodiment proposes a kind of ammonium nitrate calcium magnesium solution and prepares the method for calcium sulfate, potassium nitrate, potassium magnesium nitrate and magnesium carbonate simultaneously, comprises the following steps:

[0078] The potassium sulfate solution with a concentration of 50wt% and the ammonium nitrate calcium magnesium solution with a concentration of 32wt% are in a mass ratio of 5:7, and the decalcification reaction is carried out at 20°C for 6 hours, and filtered in a filter to obtain the decalcification solution and potassium sulfate.

[0079] Wash (one wash) the potassium sulfate after the above-mentioned filtration with water for the first time, and the lotion (one lotion) after one wash is used as the solvent of the next batch of calcium sulfate, and the solid phase is carried out with water for the second time after one wash. Washing (secondary washing), the washing liquid after the second washing (secondary washing liquid) is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap