Multi-component resource utilization method for iron tailings

A technology of iron tailings and multi-components, applied in chemical instruments and methods, aluminum chloride, aluminum halide, etc., can solve the problems of difficult disposal of iron tailings and high cost of comprehensive utilization, achieve wide application and reduce acid consumption , the effect of improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

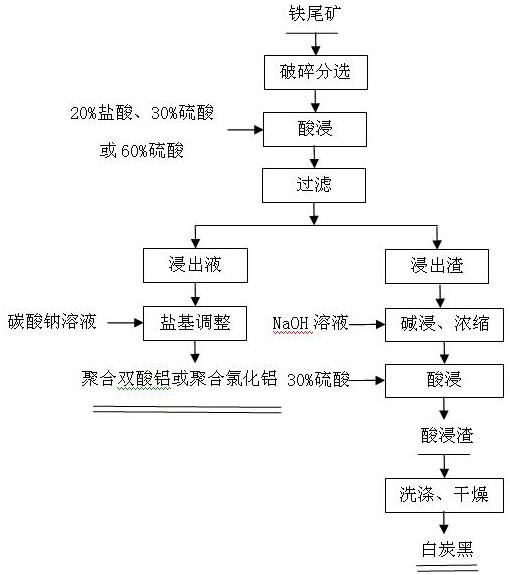

Method used

Image

Examples

Embodiment 1

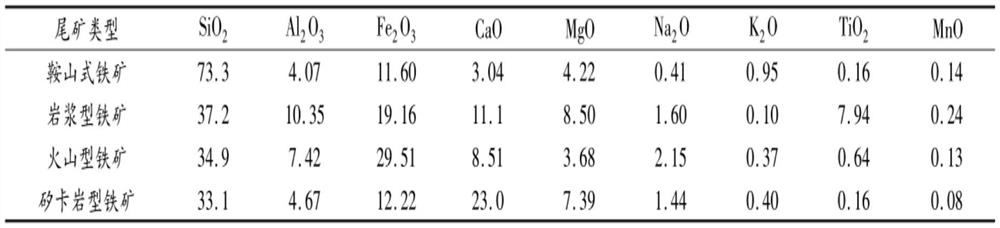

[0023] Classification and separation equipment is used to classify and separate iron tailings according to the size of Al in iron tailings 2 o 3 and SiO 2 There is a negative correlation between the content and the strength, and the tailings pellets with a particle size of 95-115 mesh are sorted out to increase the aluminum-silicon content of the tailings pellets after sorting;

[0024] First add a certain amount of tailings pellets in the heating furnace, then add excess hydrochloric acid with a mass fraction of 20% and 1mol / mol Al ion mass fraction with 30% sulfuric acid at 120 Under the condition of ℃, stir to make the raw materials fully dissolve and react with the acid; after acid leaching, cool down to 80 ℃, filter while it is hot, and filter the residue for use, add sodium carbonate to the leaching solution to adjust the basicity of the solution to 60%, and obtain the liquid product polymerized aluminum bis-acid. The purity is 96.7%.

[0025] Adding 5mol / mol Al ion c...

Embodiment 2

[0028] Classification and separation equipment is used to classify and separate iron tailings according to the size of Al in iron tailings 2 o 3 and SiO 2 There is a negative correlation between the content and the strength, and the tailings pellets with a particle size of 95-115 mesh are sorted out to increase the aluminum-silicon content of the tailings pellets after sorting;

[0029] First add a certain amount of tailings pellets into the heating furnace, then add hydrochloric acid with a mass fraction of 20% and 1.5 mol / mol of Al ions with a mass fraction of 30% sulfuric acid at 130°C in the heating furnace Stir to make the raw material fully dissolve and react with the acid; after acid leaching, cool down to 80°C, filter while it is hot, and filter the residue for use, add sodium carbonate to the leaching solution to adjust the basicity of the solution to 80%, and obtain a liquid product, polymeric aluminum bis-acid, with a purity of 98.2%.

[0030] Adding 4mol / mol Al ...

Embodiment 3

[0033] Classification and separation equipment is used to classify and separate iron tailings according to the size of Al in iron tailings 2 o 3 and SiO 2 There is a negative correlation between the content and the strength, and the tailings pellets with a particle size of 95-115 mesh are sorted out to increase the aluminum-silicon content of the tailings pellets after sorting;

[0034] First add a certain amount of tailings pellets into the heating furnace, and then add hydrochloric acid with a mass fraction of 20% and 2 mol / mol Al ions with a mass fraction of 30% sulfuric acid in the heating furnace at 140°C , stirring to fully dissolve and react the raw materials with the acid; after acid leaching, cool down to 80°C, filter while it is hot, add sodium carbonate to the leaching solution to adjust the basicity of the solution to 70%, and obtain a liquid product, polymeric aluminum bis-acid, with a purity of 97.4%.

[0035] Adding 3mol / mol Al ion concentration after washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com