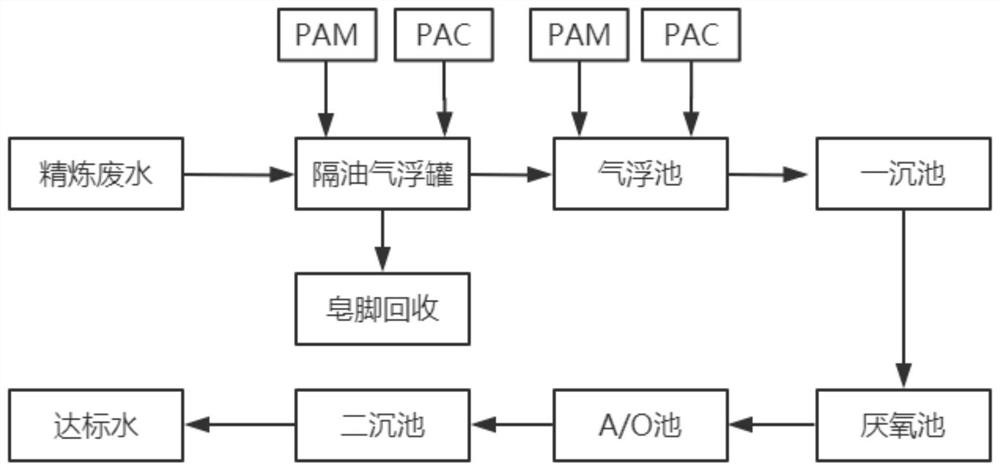

Grease refining wastewater treatment process

A wastewater treatment and process technology, applied in biological water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as environmental pollution, high operating costs, and death of aquatic organisms, and achieve Cost reduction, obvious effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1. Pour 100T / D refining wastewater into the oil separation air flotation tank, and use the dosing pump to add PAM and PAC. PAC, its dosage is 80ppm, using a stirring system for stirring, the stirring time is 20min, and then coagulation, flocculation and sedimentation are carried out, and the slick oil is recovered from soapstock;

[0036] Step 2. Send the wastewater separated from the oil-separating air flotation tank into the air flotation tank. The pH value of the wastewater in the air flotation tank is controlled between 9, and the dosing pump is used to add PAM and PAC, and the concentration of PAM is 0.3%. , The dosage is 2ppm, the dosage is 5% of PAC, the dosage is 80ppm, the stirring system is used for stirring, the stirring time is 20min, and then the coagulation, flocculation and precipitation are carried out;

[0037] Step 3, sending the waste water separated from the air flotation tank into a settling tank for sedimentation and separation through the wat...

Embodiment 2

[0042] Step 1. Pour 100T / D refining wastewater into the oil separation air flotation tank, and use the dosing pump to add PAM and PAC. PAC, its dosage is 100ppm, using a stirring system for stirring, the stirring time is 20min, and then coagulation, flocculation and sedimentation are carried out, and the slick oil is recovered from soapstock;

[0043] Step 2. Send the wastewater separated from the oil-separating air flotation tank into the air flotation tank. The pH value of the wastewater in the air flotation tank is controlled between 9, and the dosing pump is used to add PAM and PAC, and the concentration of PAM is 0.3%. , The dosage is 2ppm, the dosage is 5% of PAC, the dosage is 100ppm, the stirring system is used for stirring, the stirring time is 20min, and then the coagulation, flocculation and precipitation are carried out;

[0044] Step 3, sending the waste water separated from the air flotation tank into a settling tank for sedimentation and separation through the w...

Embodiment 3

[0049]Step 1. Pour 100T / D refining waste water into the oil-separating air flotation tank, use a dosing pump to add PAM and PAC, and add PAM with a concentration of 0.3%, the dosage is 10ppm, and the concentration is 5%. PAC, its dosage is 80ppm, using a stirring system for stirring, the stirring time is 20min, and then coagulation, flocculation and sedimentation are carried out, and the slick oil is recovered from soapstock;

[0050] Step 2. Send the wastewater separated from the oil-separating air flotation tank into the air flotation tank. The pH value of the wastewater in the air flotation tank is controlled between 9, and the dosing pump is used to add PAM and PAC, and the concentration of PAM is 0.3%. , The dosage is 10ppm, the dosage is 5% of PAC, the dosage is 80ppm, the stirring system is used for stirring, the stirring time is 20min, and then the coagulation, flocculation and precipitation are carried out;

[0051] Step 3, sending the waste water separated from the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com