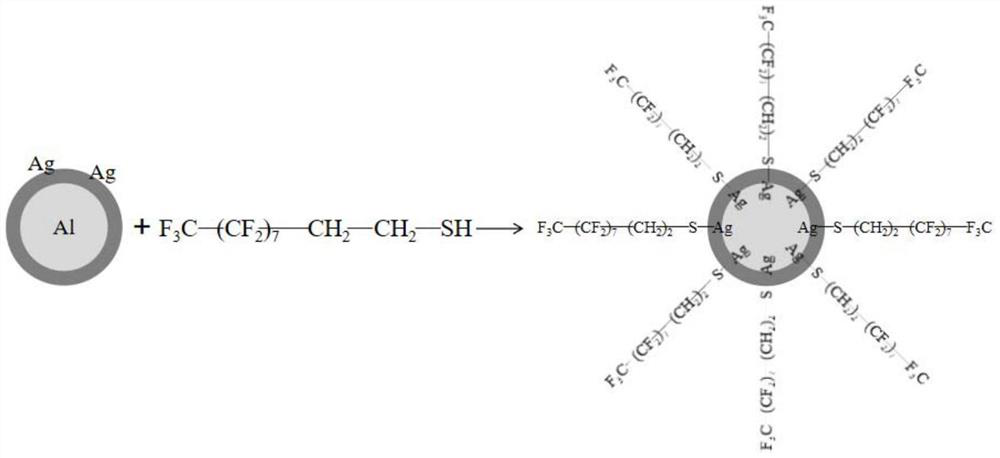

Salt-fog-resistant silver-plated aluminum powder conductive coating and preparation method thereof

A conductive coating, silver-plated aluminum technology, applied in the field of salt spray-resistant silver-plated aluminum powder conductive coating and its preparation, can solve the problem of insufficient salt spray resistance of the conductive coating, and improve the overall economic benefits and operation principles. Simple and easy to implement, avoids the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention discloses a preparation method of a salt-spray-resistant silver-plated aluminum powder conductive coating, which specifically comprises the following steps:

[0038] Step 1, aluminum powder pretreatment

[0039] Step 1.1, cleaning and removing impurities: take some aluminum powder, put it in ethanol aqueous solution (absolute ethanol: deionized water is 2~3:1) and ultrasonically treat at 80Hz~100Hz for 15~20min, then wash with water and filter 2~3 times , to obtain the processed aluminum powder for subsequent use;

[0040] Through cleaning and removing impurities, it is possible to clean the surface of aluminum powder and remove organic impurities. Because aluminum powder is prepared with special oil, there are a lot of oil stains on the surface, and ethanol, as a good organic solvent, can remove most of the oil stains and ensure aluminum The surface of the powder is clean to ensure a clean surface and provide a basis for subsequent modification.

[0041...

Embodiment 1

[0060] Step 1, pretreatment of aluminum powder (the aluminum powder is spherical aluminum powder with a particle size of 5 μm)

[0061] Step 1.1, cleaning and removing impurities: Weigh 50g of aluminum powder, put it in 600mL of ethanol aqueous solution (400mL of absolute ethanol, 200mL of deionized water) for 80Hz ultrasonic treatment for 20min, then wash with water and suction filter 3 times to obtain the treated aluminum powder, spare;

[0062] Step 1.2, 2-methoxy-4-methylphenol coating treatment to obtain reduced aluminum powder coated with a reduced layer on the surface: place the aluminum powder treated in step 1.1 in 2g / L 2-methoxy-4- Carry out the surface modification reaction in the methylphenol aqueous solution, the dosage of 2-methoxyl-4-methylphenol is 2.5g, the dosage of 2-methoxyl-4-methylphenol is 5% of the quality of aluminum powder, and then use trihydroxy Adjust the pH to 8.5 with methylaminomethane (tris), place it in a constant temperature magnetic stirrer...

Embodiment 2

[0075] Step 1, pretreatment of aluminum powder (the aluminum powder is a spherical aluminum powder with a particle size of 35 μm)

[0076] Step 1.1, cleaning and removing impurities: Weigh 50g of aluminum powder, put it in 600mL of ethanol aqueous solution (400mL of absolute ethanol, 200mL of deionized water) for 80Hz ultrasonic treatment for 20min, then wash with water and suction filter 3 times to obtain the treated aluminum powder, spare;

[0077] Step 1.2, 2-methoxy-4-methylphenol coating treatment to obtain reduced aluminum powder coated with a reduction layer on the surface: place the aluminum powder treated in step 1.1 in 4g / L 2-methoxy-4- Carry out the surface modification reaction in the methylphenol aqueous solution, the dosage of 2-methoxyl-4-methylphenol is 5g, the dosage of 2-methoxyl-4-methylphenol is 10% of the quality of aluminum powder, and then use trimethylol Tris was adjusted to PH to 8.5, placed in a constant temperature magnetic stirrer, and reacted in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com