High-skid-resistance water-based gloss oil

A water-based varnish and anti-slip technology, which is applied in coatings, polyester coatings, etc., can solve the problems of low anti-slip angle, high Tg value of pure acrylic emulsion, and difficulty in meeting the high anti-slip requirements of anti-slip varnish, so as to improve rheology , good storage stability, the effect of ensuring storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

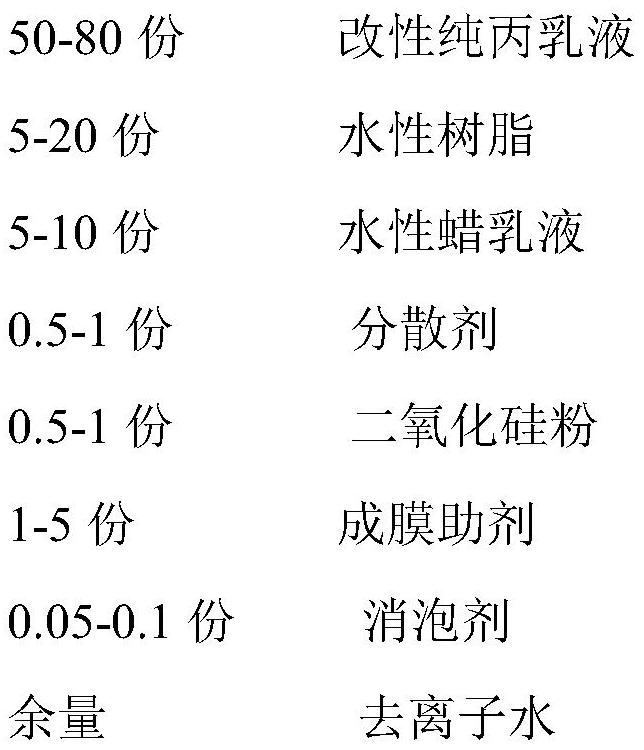

[0023] Embodiment 1 A kind of high antiskid water-based glazing oil, this water-based glazing oil is made up of the following components by weight (total 100 parts):

[0024]

[0025]

[0026] The preparation method of the water-based glazing oil of this embodiment is: take modified pure acrylic emulsion, add water-based resin, water-based wax emulsion, dispersant, silica powder, film-forming aid, defoamer and deionized For water, stir mechanically for 5 minutes after each component is added, then add the next component until the addition is complete, and continue stirring for 5 minutes to obtain a high anti-slip water-based varnish.

Embodiment 2

[0027] Embodiment 2 A kind of high anti-slip water-based glazing oil, the water-based glazing oil is composed of the following components by weight (total 100 parts):

[0028] raw material Raw material model factory parts by weight Modified pure acrylic emulsion SD-900 Shengda 80 water-based resin HMS-389-9H hemings 5 Water-Based Wax Emulsion 2541 Longhai Chemical 9 Water-Based Wax Emulsion 255 Longhai Chemical 0.5 Silica powder C803 Grace 1 Dispersant 1240 Longhai Chemical 1 Coalescent Ethylene glycol butyl ether alpha 2 Defoamer YCK-700 YCK 0.1 Deionized water Applicant self-made margin

[0029] The preparation method of the water-based glazing oil of this embodiment is: take modified pure acrylic emulsion, add water-based resin, water-based wax emulsion, dispersant, silica powder, film-forming aid, defoamer and deionized For water, stir mechanically for 5 minutes after e...

Embodiment 3

[0030] Embodiment 3 A kind of high anti-slip water-based varnish, the water-based glazing oil is composed of the following components by weight (total 100 parts):

[0031]

[0032]

[0033] The preparation method of the water-based glazing oil of this embodiment is: take modified pure acrylic emulsion, add water-based resin, water-based wax emulsion, dispersant, silica powder, film-forming aid, defoamer and deionized For water, stir mechanically for 5 minutes after each component is added, then add the next component until the addition is complete, and continue stirring for 5 minutes to obtain a high anti-slip water-based varnish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com