Waxing equipment

A kind of equipment and technology for scalding wax, which can be used in the processing of textile material equipment configuration, textile and papermaking, liquid/gas/steam textile material processing, etc. Good, good recycling effect, and the effect of ensuring environmental safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

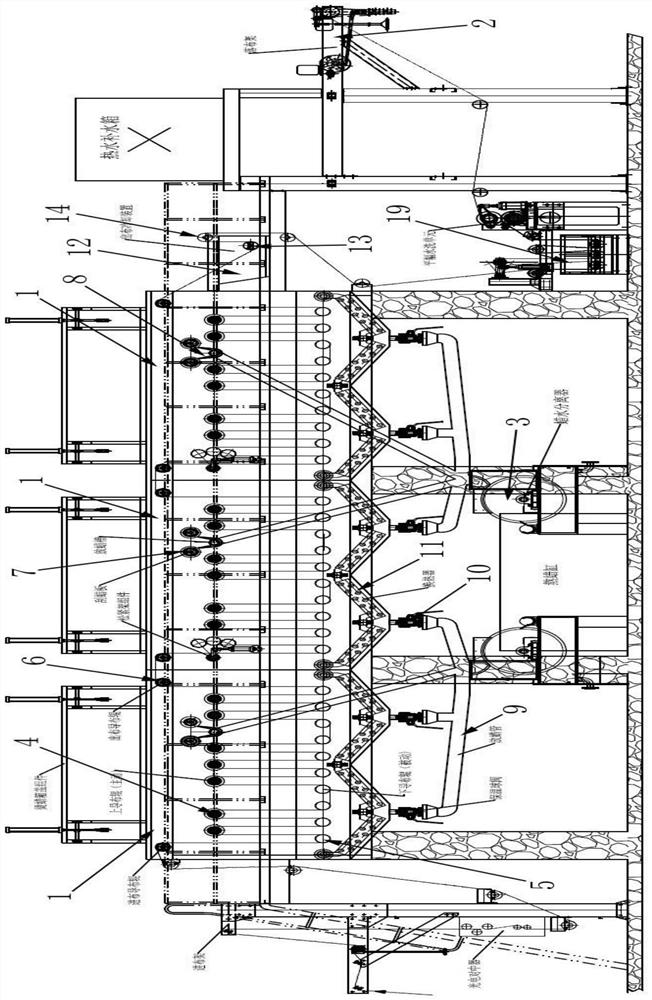

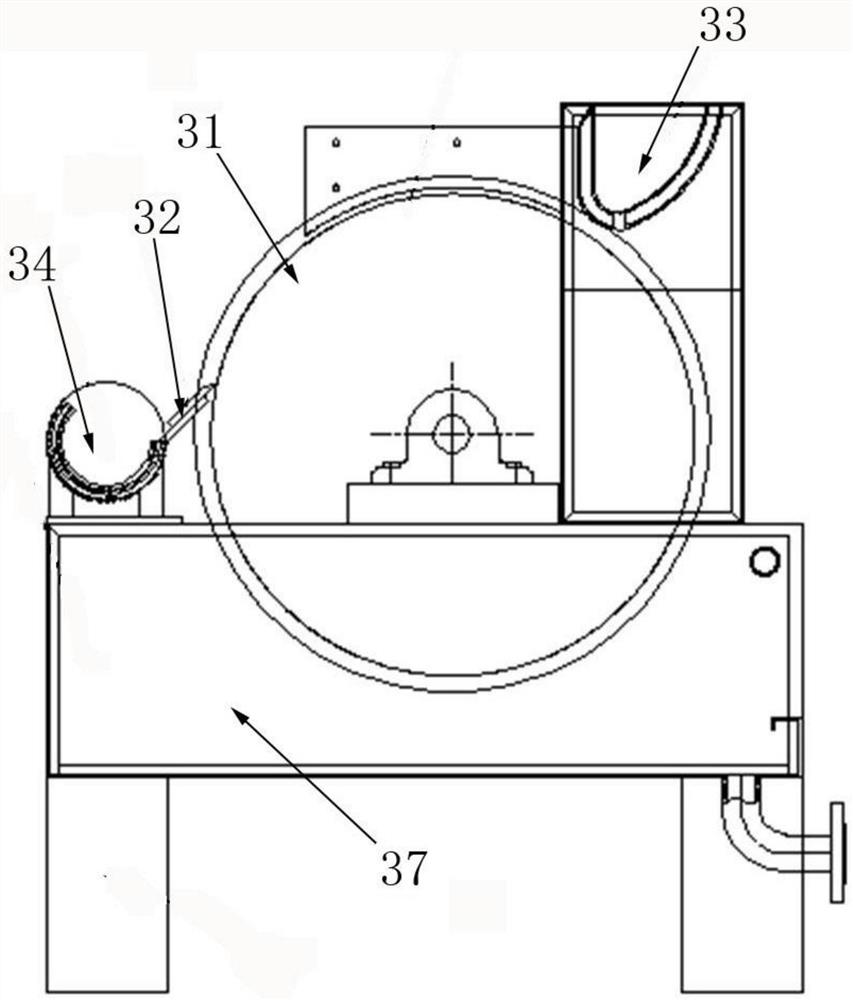

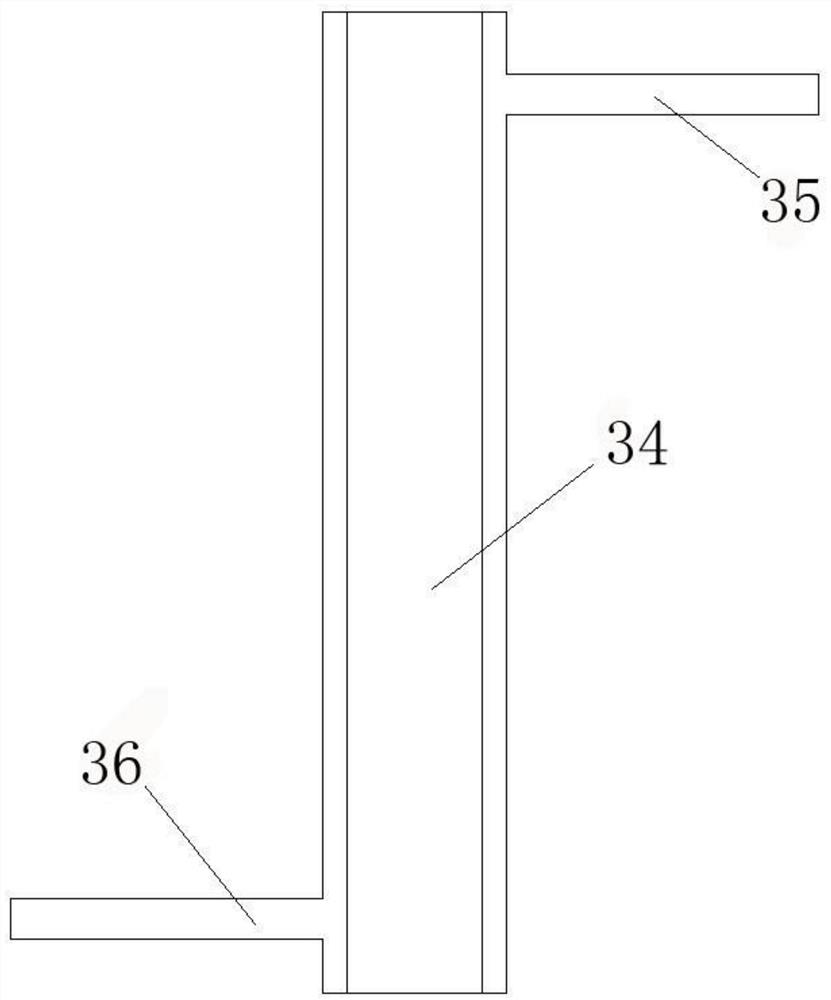

[0032] Such as Figure 1-7 As shown, a kind of waxing equipment provided by the present invention uses physical wax removal to improve the efficiency of wax removal, and at the same time reduces the damage of rosin wax to improve the recycling rate of rosin wax. The present invention includes a waxing water tank 1, which is provided with a cloth guiding mechanism and a wax water recovery device, and the wax water recovery device is connected with a wax water separation device 3 . The waxing water tank 1 has at least two, preferably three, and the three waxing water tanks 1 are distributed side by side in turn, and the bottom of the waxing water tank 1 is provided with a heat exchanger 11 for warming the hot water of the waxing water tank The cloth guiding mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com