Coating agent, fast-charging graphite, preparation method and application of fast-charging graphite and battery

A coating agent and graphite technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor stability and fast charging performance of fast-charging graphite, and the feasibility of the preparation method and the cost cannot be taken into account, and achieve excellent The effect of fast insertion, excellent release ability and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

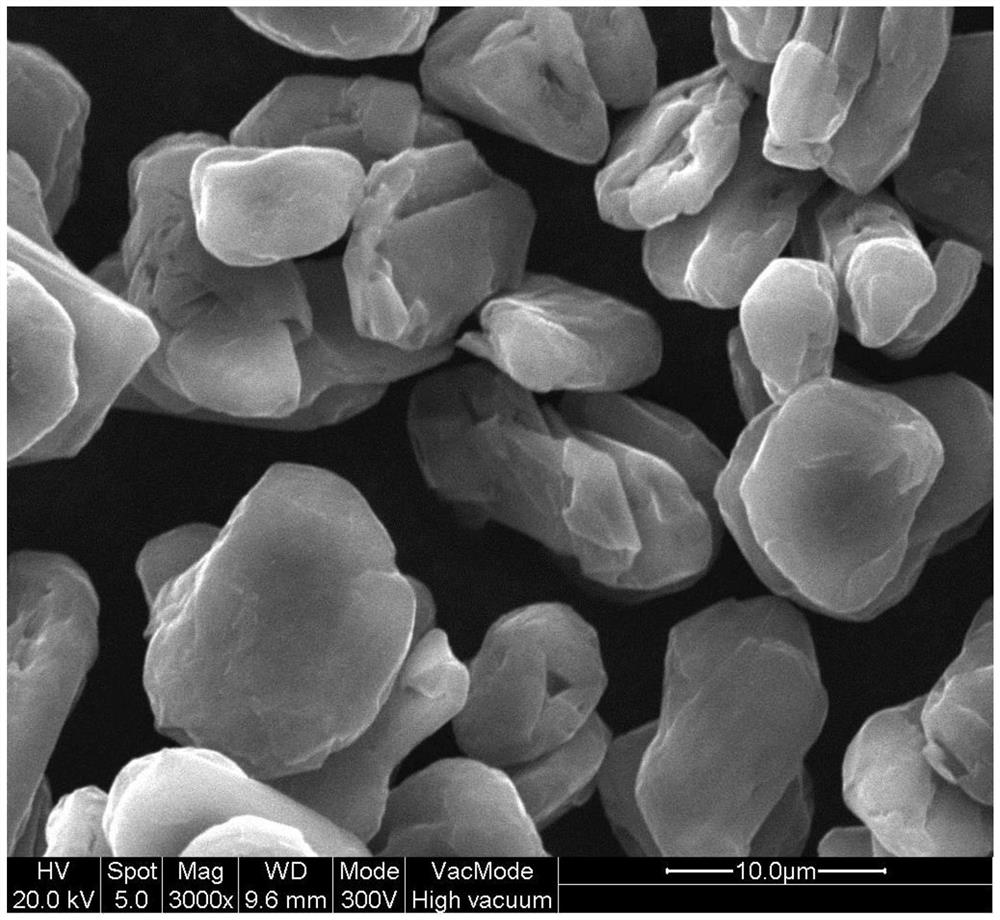

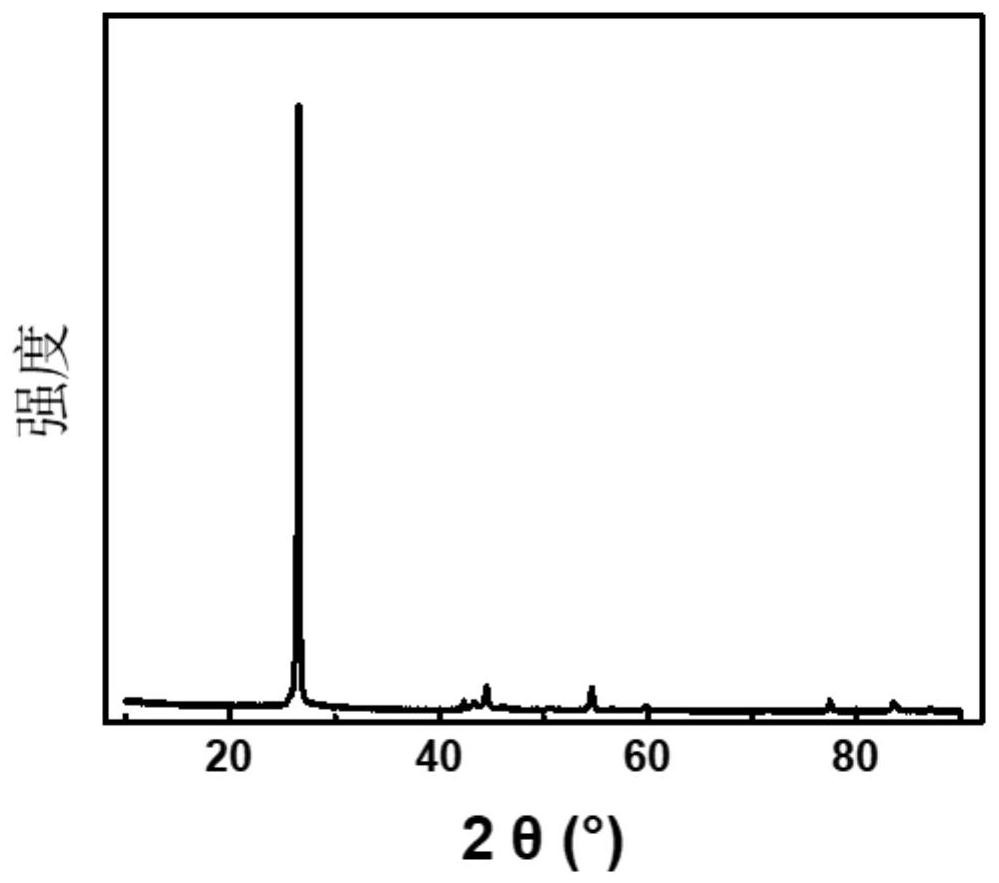

Image

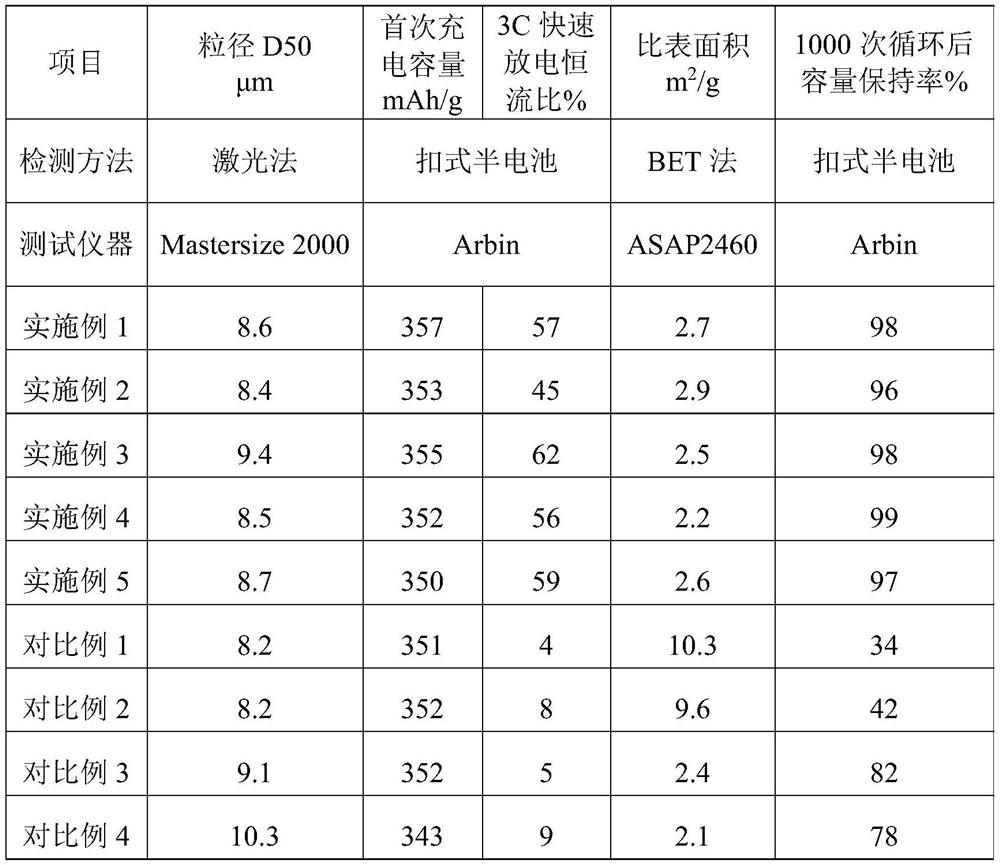

Examples

Embodiment 1

[0070] 1. Preparation of amphiphilic carbon materials

[0071] Using petroleum coke crushed to less than 10 μm as raw material, the amphiphilic carbon material was prepared by the mixed acid method. The specific process was as follows: firstly, 500 mL of mixed acid of concentrated nitric acid and concentrated sulfuric acid was prepared according to the volume ratio of 3:7, and then 100 g of petroleum coke was added. Stir and reflux at ℃ for 3 hours, filter to obtain a filter cake after cooling, and wash the filter cake until neutral to obtain a petroleum coke-based amphiphilic carbon material. According to GB / T 268-1987, the carbon residue value of the petroleum coke-based amphiphilic carbon material is 61%.

[0072] 2. Preparation of coating agent

[0073] Dissolve ethylenediamine in water to obtain an alkaline solution with a pH value of 13 (tested by pH test paper), then dissolve the prepared petroleum coke-based amphiphilic carbon material in the alkaline solution, and fi...

Embodiment 2

[0081] Except that in the step S1 of the preparation of fast-charging graphite, the coating agent (calculated according to the carbon residue value): natural graphite = 5:100 is used for batching, the other conditions and steps are the same as in Example 1.

Embodiment 3

[0083] Except that artificial graphite is used in step S1 of the preparation of fast-charging graphite, other conditions and steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com