Gas turbine power plant wastewater circulating purification equipment

A technology of wastewater recycling and purification equipment, applied in natural water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of unevenness, the effect of wastewater treatment and purification cannot be effectively guaranteed, and the purification effect of wastewater treatment is not good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

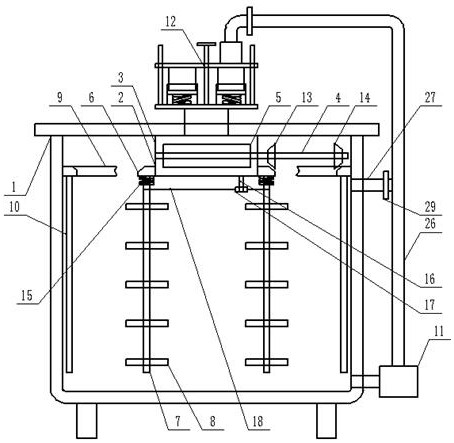

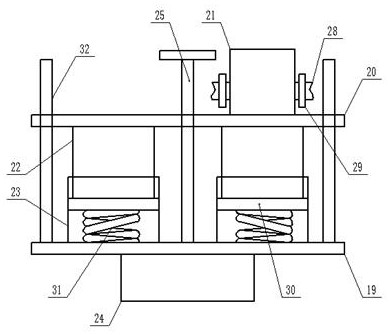

[0013] Embodiment 1: see figure 1 , figure 2 , A kind of waste water circulation purification equipment of gas turbine power plant provided by the present invention is now described, 1. A kind of waste water circulation purification equipment of gas turbine power plant, comprising a hollow cylindrical mixing body 1, characterized in that the mixing body 1 A mixing mechanism 2 is provided inside, and the mixing mechanism 2 includes a barrel-shaped frame body 3 fixed in the middle of the top of the mixing body 1, a circular shaft 4 horizontally arranged in the barrel-shaped frame body 3, and a barrel-shaped frame Inside the body 3 and located on the outside of the circular shaft 4, there is a guide vane 5 that is evenly provided with an equal arc, the first annular frame body 6 that is movable on the outer wall of the lower end of the barrel-shaped frame body 3, and the lower end of the first annular frame body 6 is vertically uniform. The mixing shaft 7 provided, the mixing r...

Embodiment 2

[0014] Example 2: see figure 1 , a kind of gas turbine power plant wastewater circulation purification equipment provided by the present invention will now be described. The outer bottom of the mixer body 1 is vertically and evenly fixed with supporting legs, and the top of the mixer body 1 is provided with a water inlet and a drug injection port. 1. There is a water outlet at the bottom, a first annular groove is formed on the outer side wall of the lower end of the barrel-shaped frame body 3, and the inner end wall of the first annular frame body 6 is movably placed in the first annular groove. One end of the circular shaft 4 in the length direction moves through the inner end wall of the barrel-shaped frame body 3 and protrudes, and a first transmission gear is sleeved on the outside of the protruding end of the circular shaft 4 and corresponds to the position of the first annular frame body 6 13. The outer circumferential end wall of the first annular frame body 6 is unifo...

Embodiment 3

[0015] Embodiment 3: see figure 1 , a kind of waste water circulation and purification equipment for a gas turbine power plant provided by the present invention will now be described. The top of the mixing shaft 7 is covered with torsion springs 15, and the ends of the torsion springs 15 are evenly connected to the first annular frame body. 6. The lower end wall is fixedly connected, and the other end is fixedly connected to the outer end wall of the mixing shaft 7. The lower end edge of the barrel frame body 3 is vertically fixed with a traction rope connecting column 16, and the traction rope connecting column The outer end of the 16 bottom end is covered with an annular traction rope connecting frame 17, and a bearing-shaped connector is provided between the inner end wall of the annular traction rope connecting frame 17 and the outer end wall of the traction rope connecting column 16, and the annular traction rope is connected A traction rope 18 is provided between the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com