Coating material as well as preparation method and application thereof

A technology of outer covering materials and raw materials, applied in the field of polymer materials, can solve problems such as smoothness, fineness, softness, scratch resistance and chemical resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

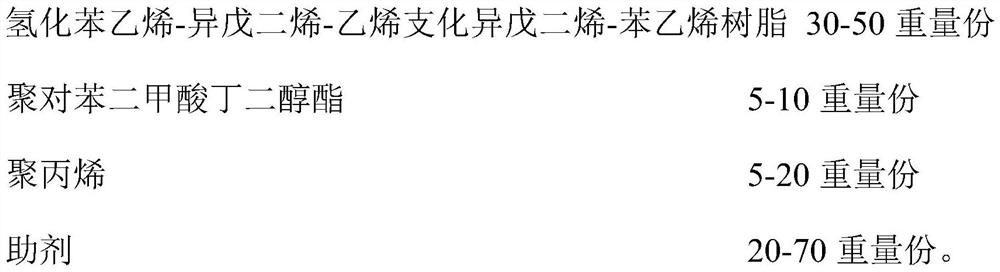

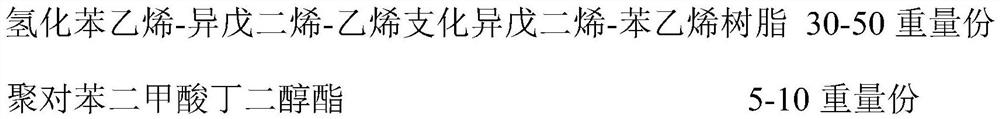

Method used

Image

Examples

Embodiment 1-6、 comparative example 1-6

[0049] The above-mentioned examples and comparative examples respectively provide a kind of outer covering, and the specific formula is shown in Table 1.

[0050] The preparation method of the outer coating provided in the above-mentioned examples and comparative examples is as follows:

[0051] (1) Add each substance in the formula shown in Table 1 into a 300L stirring pot, and mix at a low speed for 20 minutes in the stirring pot;

[0052] (2) Discharge the mixed raw materials in step (1) into a twin-screw machine with a diameter of 65 mm for extrusion and plasticization, and the temperature for extrusion and plasticization is 200 ° C;

[0053] (3) The extruded and plasticized rubber material is passed through a twin-screw eye mold, subjected to drawing strip water cooling, air cooling, pelletizing and packaging to obtain the outer coating material.

[0054] Performance Testing

[0055] Carry out following performance test for the outer cover that above-mentioned embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com