Novel oil tanker flue gas inert system detection device and method

A detection device and flue gas technology, which is applied in the direction of measuring device, lubrication indicator device, heat measurement, etc., can solve the problem of inaccurate data monitoring and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

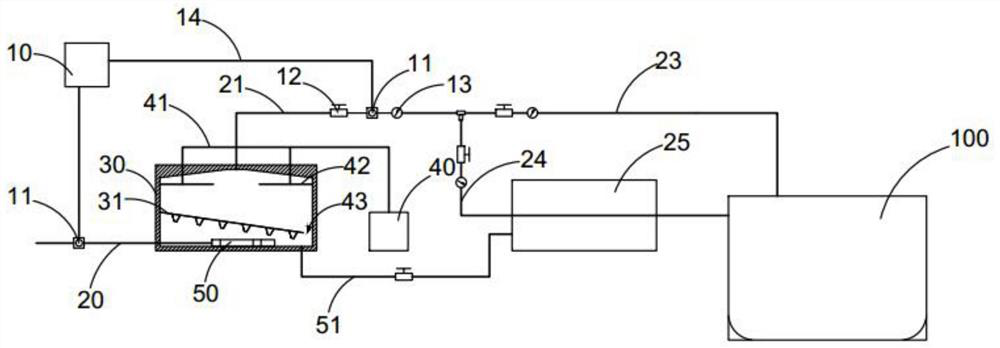

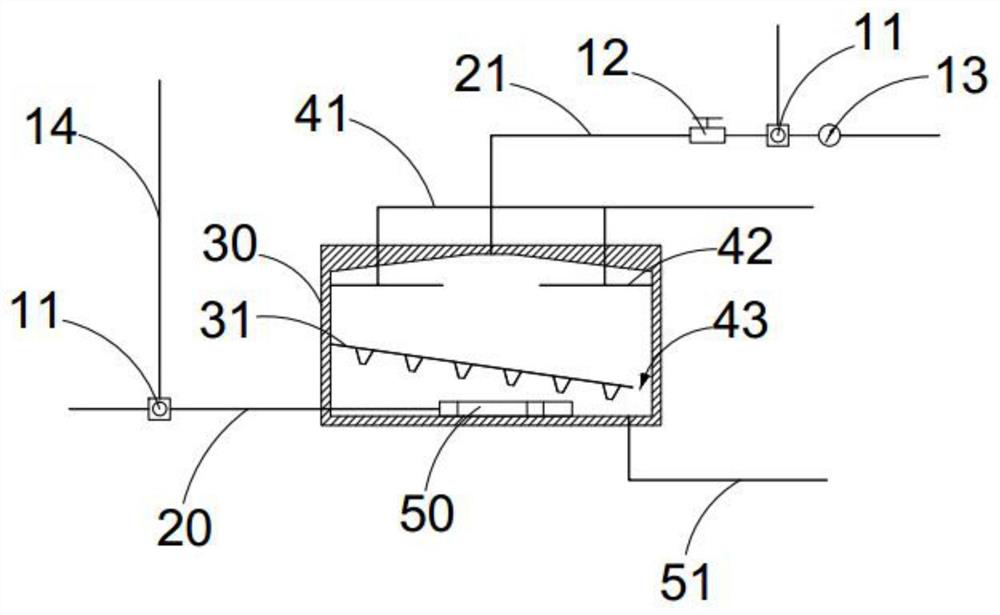

[0035] See attached Figure 1-6 As shown, a novel oil tanker flue gas inert system detection device and method, including:

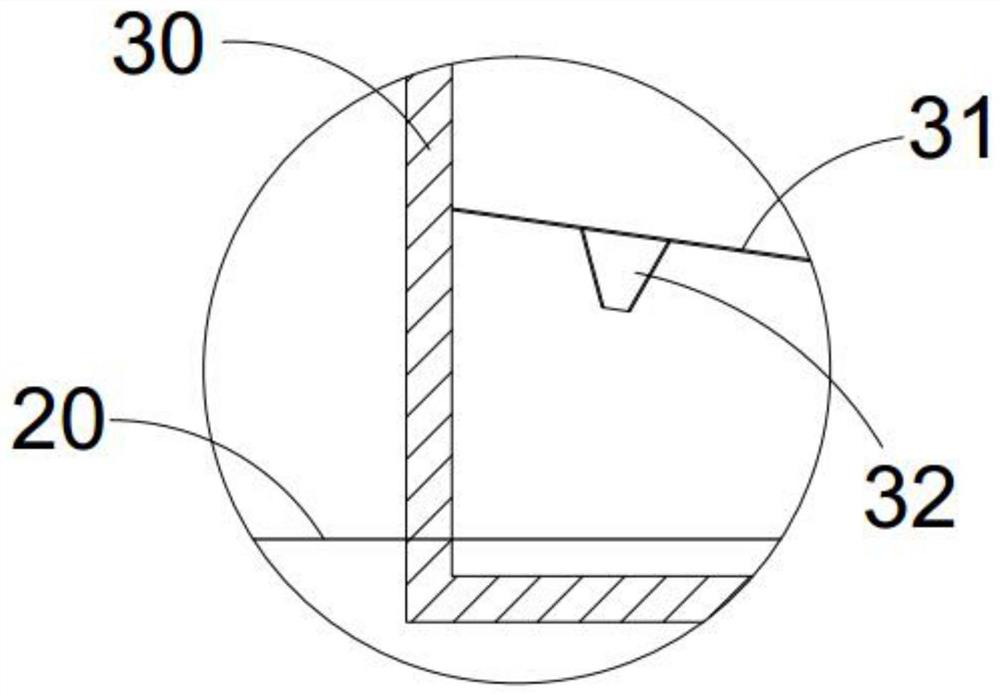

[0036] The gas pipe body 20 is used to transport flue gas,

[0037] The flue gas purifier 30, the flue gas purifier 30 is provided with a spray pipe 42, the spray pipe 42 is connected with the water pump 40 arranged outside the flue gas purifier 30 through the first water pipe 41, the gas pipe body 20 is connected with the flue gas The purifier 30 communicates and sends the flue gas to the inner bottom of the flue gas purifier 30,

[0038] The first flue gas exhaust pipe 21, one end of the first flue gas exhaust pipe 21 communicates with the upper part of the flue gas purifier 30, and the other end is connected to a three-way pipe, one of which is connected to the second flue gas exhaust pipe 23, and the second flue gas The exhaust pipe 23 communicates with the ship's oil storage tank 100, and the other nozzle is connected to the third smoke exhaust pi...

Embodiment 2

[0053] The further optimization scheme of present embodiment on the basis of embodiment 1 is: see appendix Figure 7 , 8 As shown, a coaxial auxiliary rectifying element 80 is also provided in the rectifying sleeve body 70. The auxiliary rectifying element 80 includes a tapered ball bearing 81 connected to the inner wall of the rectifying sleeve body 70. The main disk body 85, the disk surface of the rotating main disk body 85 is respectively provided with a first through hole 82 and a third through hole 83 which are arranged around and through, and the middle part of the rotating main disk body 85 is connected with a rotatable rotating cylinder 84, and the rotating cylinder Rotating blades 86 are arranged on the cylinder side of 84, and the two ends of the rotating cylinder 84 can be respectively connected with the rotating main disk 85. In the present invention, the auxiliary rectifier 80 arranged inside the rectifying sleeve body 70 is used to realize the spiral trajectory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com