Sorting method for guiding mechanical arm to grab materials with different poses based on ConvPoint model

A technology of manipulator and pose, which is applied in the sorting field based on the ConvPoint model to guide the manipulator to grab materials in different poses. Line and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below.

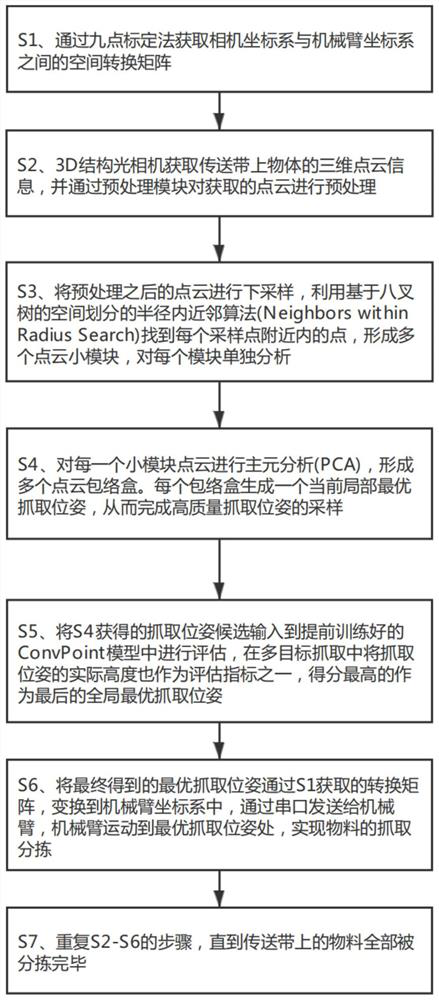

[0043] As shown in the figure, the sorting system used in the present invention includes a 3D structured light camera, a mechanical arm and a computer. The 3D structured light camera is used to take images of materials on the conveyor belt of the flexible production line and feed them back to the computer. The computer is used to process the images taken. After processing, control the robotic arm to sort different materials on the conveyor belt of the flexible production line. The specific steps are:

[0044] S1. Obtain the space transformation matrix between the camera coordinate system and the manipulator coordinate system through the nine-point calibration method, specifically:

[0045] First, the end fixture of the mechanical arm is controlled by the teaching pendant to move to 9 points on the calibration board to obtain the coordinates in the robot coordinate system. At the same time, the 3D structured light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com