Cleaning tool of foaming machine, foaming machine and cleaning method of foaming machine

A technology of foaming machines and cleaners, applied in the field of foam processing, which can solve problems such as increased labor intensity of staff, hidden safety hazards, and low cleaning efficiency, so as to reduce labor costs and production costs, avoid splashing and scattering, and reduce labor costs. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

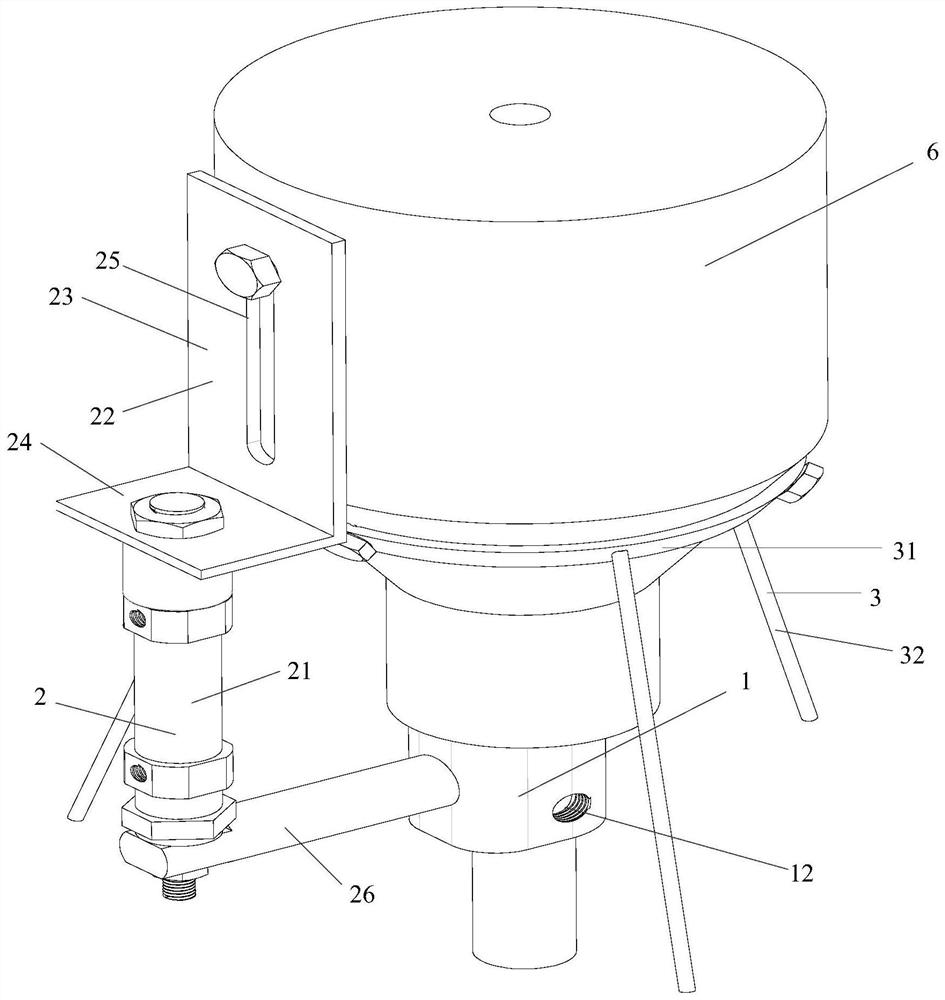

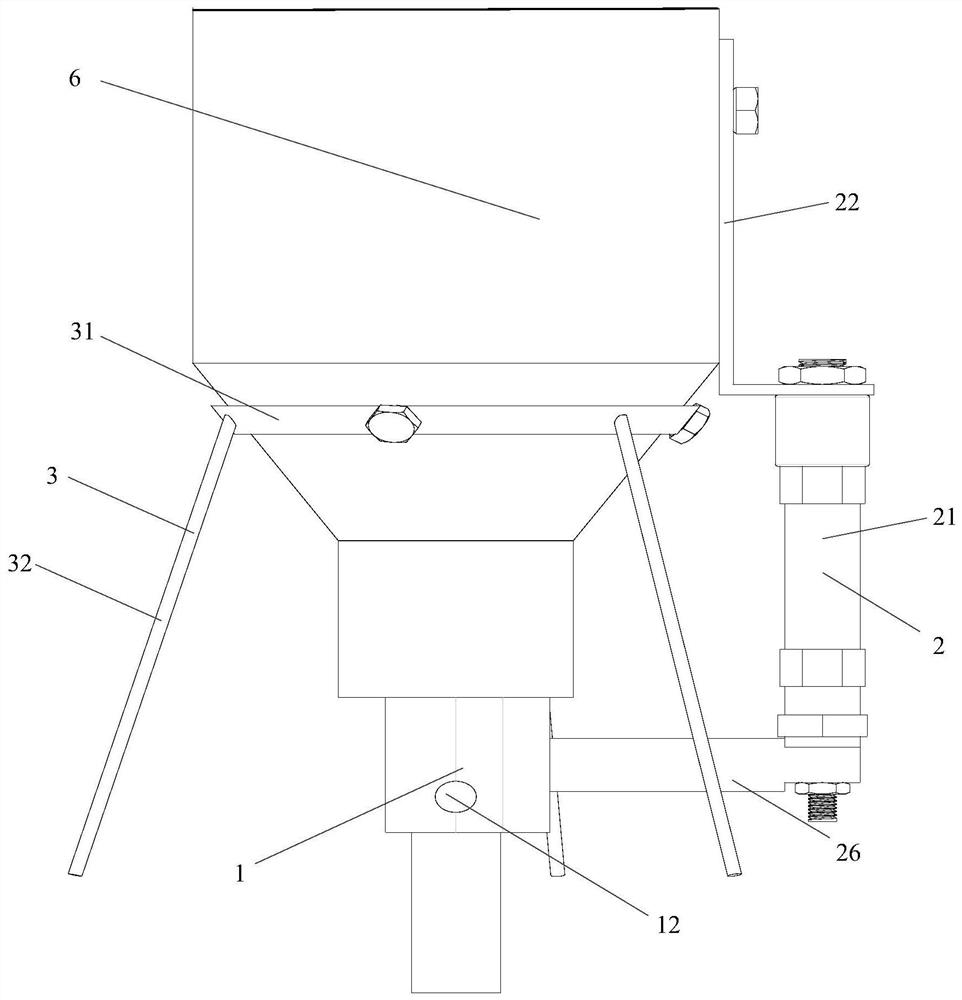

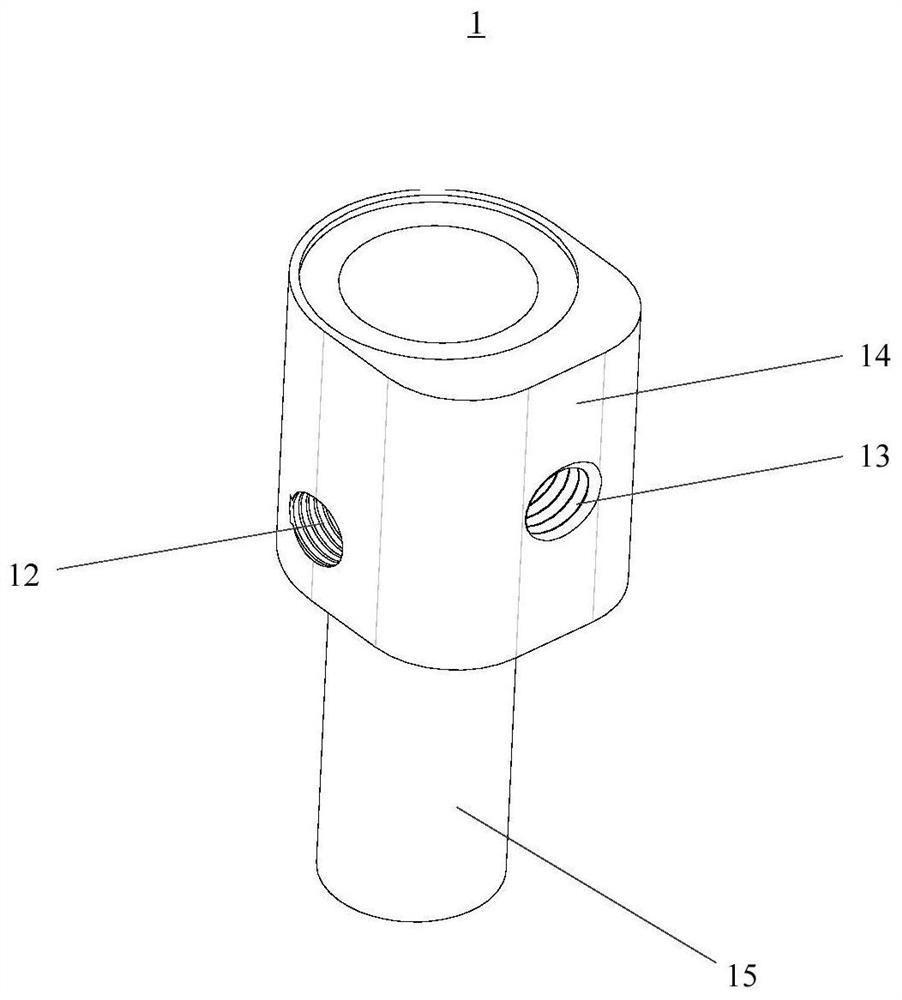

[0041] Such as figure 1 , figure 2 and Figure 7 to Figure 10 As shown, this embodiment provides a cleaning tool for a foaming machine, the cleaning tool includes: a self-cleaning outer tube 1, which is sleeved on the outside of the foaming gun barrel 61 and at least partially accommodates the foaming gun barrel 61, The self-cleaning outer tube 1 is provided with at least one air intake hole 12; the air intake hole 12 is used to communicate with the compressed air source through the intake pipe; Move down so that the foaming gun barrel 61 closes or opens the air intake hole 12; the compressed air source can exhaust the air into the opened air intake hole 12 through the air intake pipe to clean the inner wall of the self-cleaning outer tube 1.

[0042] Such as Figure 7 As shown, during the foaming and pouring process, the air inlet 12 is closed by the foaming gun barre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com