Solvent-free synthetic leather polyurethane composite material and preparation method thereof

A technology of polyurethane composite material and synthetic leather, which is applied in coating, textile and papermaking, etc., can solve problems such as unfavorable operation, short film forming time, poor hydrolysis resistance, etc., and achieve improved thixotropy, good mechanical properties, flow Good hanging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

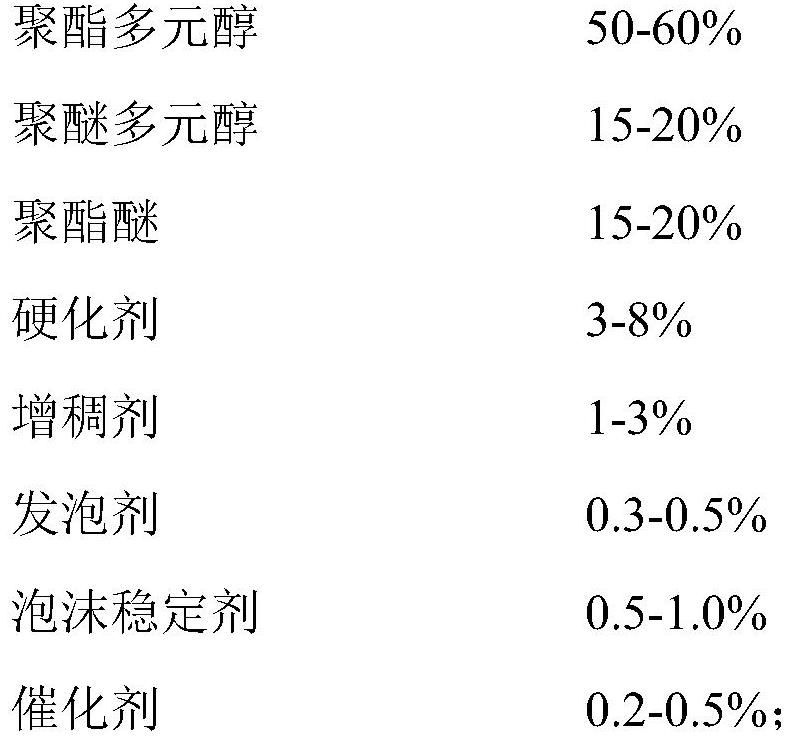

[0031] Prepare foamed polyurethane sealant for batteries by the following raw material ratio and method:

[0032] Group A is divided into:

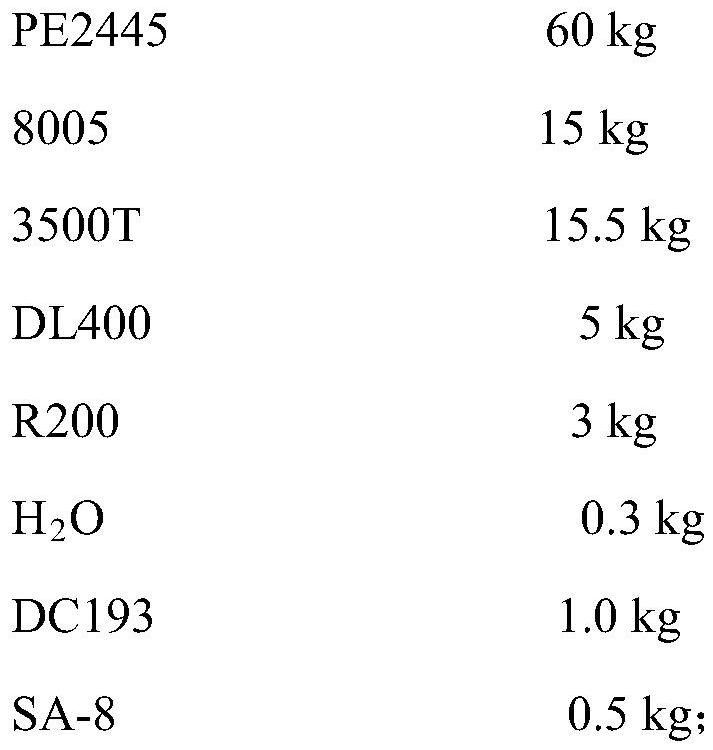

[0033]

[0034] Group B is divided into:

[0035] DXD-3310B 100kg.

[0036] Weigh 60kg of PE2445, 15kg of 8005, 15.5kg of 3500T, 5kg of DL400, 3kg of R200, 0.3kgH 2 O, 1.0kg of DC193 and 0.5kg of SA-8 were put into the reaction kettle and stirred, the temperature was raised to 50°C, the rotation speed was 40 rpm, and stirred for 0.5 hours to obtain component A;

[0037] Mix component A and component B (DXD-3310B) evenly at a mass ratio of 100:50, then roll coat it on release paper, put it in an oven at 100-150°C, and take it out of the oven when the coating starts to become milky Cover it with non-woven fabric, and continue to put it into an oven at 100-150°C for aging for 3-5 minutes to obtain solvent-free polyurethane synthetic leather.

Embodiment 2

[0039] Prepare foamed polyurethane sealant for batteries by the following raw material ratio and method:

[0040] Group A is divided into:

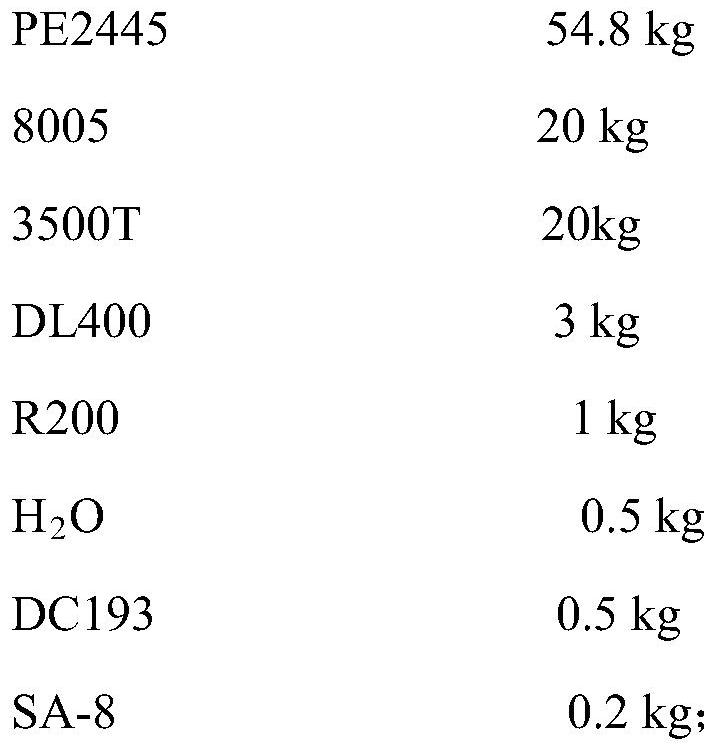

[0041]

[0042] Group B is divided into:

[0043] DXD-3310B 100kg.

[0044] Weigh 54.8kg of PE2445, 20kg of 8005, 20kg of 3500T, 3kg of DL400, 1kg of R200, 0.5kgH 2 O, 0.5kg of DC193 and 0.2kg of SA-8 were put into the reaction kettle and stirred, the temperature was raised to 60°C, the rotation speed was 50 rpm, and stirred for 1 hour to obtain component A;

[0045] Mix component A and component B (DXD-3310B) evenly at a mass ratio of 100:40, then roll coat it on release paper, put it in an oven at 100-150°C, and take it out of the oven when the coating starts to become milky Cover it with non-woven fabric, and continue to put it into an oven at 100-150°C for aging for 3-5 minutes to obtain solvent-free polyurethane synthetic leather.

Embodiment 3

[0047] Prepare foamed polyurethane sealant for batteries by the following raw material ratio and method:

[0048] Group A is divided into:

[0049]

[0050] Group B is divided into:

[0051] DXD-3310B 100kg.

[0052] Weigh 50kg of PE2445, 18kg of 8005, 18kg of 3500T, 10kg of DL400, 2.4kg of R200, 0.4kgH 2 O, 0.8kg of DC193 and 0.4kg of SA-8 were put into the reaction kettle and stirred, the temperature was raised to 55°C, the rotation speed was 55 rpm, and stirred for 50 minutes to obtain component A;

[0053] Mix component A and component B (DXD-3310B) evenly at a mass ratio of 100:50, then roll coat it on release paper, put it in an oven at 100-150°C, and take it out of the oven when the coating starts to become milky Cover it with non-woven fabric, and continue to put it into an oven at 100-150°C for aging for 3-5 minutes to obtain solvent-free polyurethane synthetic leather.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com