Liquid pumping system of piston type slurry pump with circulating cleaning device

A cleaning device, a piston-type technology, which is applied to the components of the pumping device for elastic fluids, the variable-capacity pump components, the pump, etc., can solve the problem that the mud pump cannot adapt to the large pump pressure, Insufficient liquid output, difficult piston replacement, etc., to achieve the effect of good piston sealing, easy disassembly, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

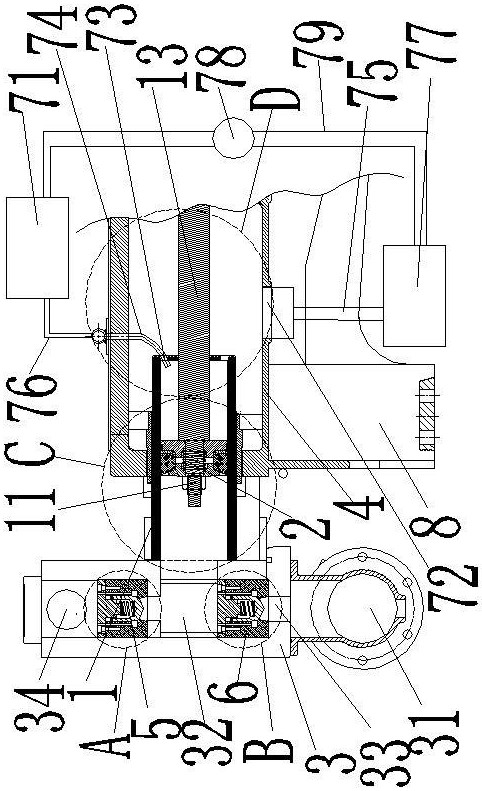

[0053] Example 1. Such as Figure 1-7 As shown, a pumping system of a piston mud pump with a circulating cleaning device is characterized in that it includes a piston rod, a piston 2, a piston tube 1, a valve box body 3, a piston tube installation tube 4, and a liquid inlet tube 31. Cleaning and lubricating device, pump body 8; the piston rod includes the left end part 11 of the piston rod and the body 13 of the piston rod arranged coaxially in the transverse direction.

[0054] The piston tube installation pipe 4 is horizontally arranged on the pump body 8, the left end of the piston tube installation pipe 4 is provided with a piston tube installation pipe end cover 41, and the centroid of the piston tube installation pipe end cover 41 is horizontally equipped with a piston tube 1, the piston tube 1 is installed with a piston 2, and the piston 2 is set on the left end part 11 of the piston rod; the right end of the piston tube 1 is provided with a piston tube end cap 12;

...

Embodiment 2

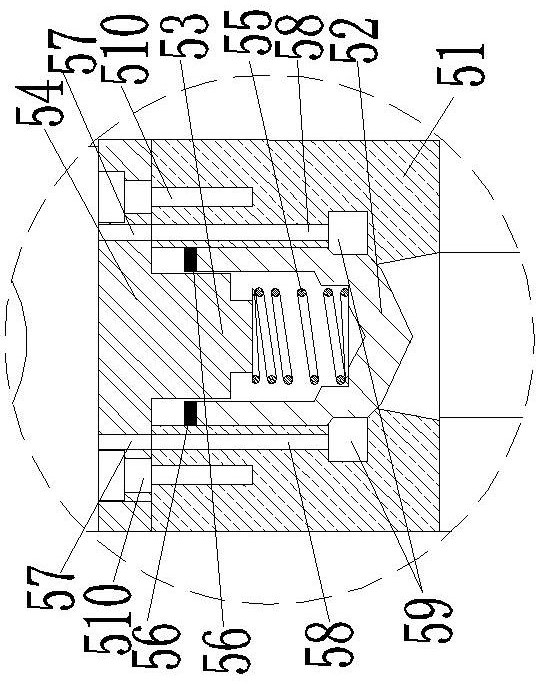

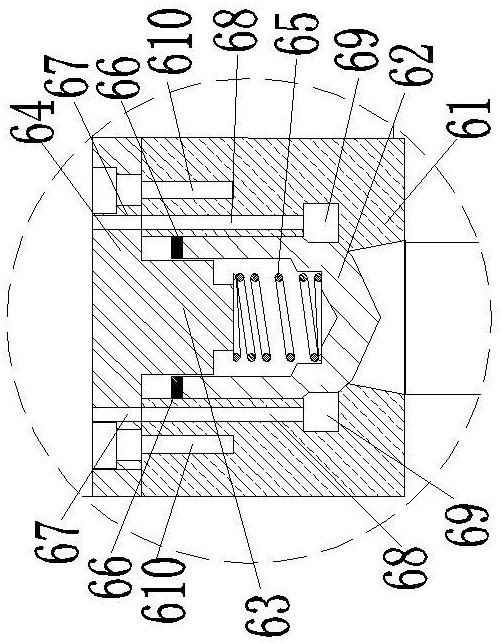

[0079] Example 2. Such as Figure 8-11 The difference between the present embodiment shown and Embodiment 1 is that: the radial outer peripheral surface of the piston tube fixing sleeve 42 is not provided with a left locking nut 43 on the left side of the piston tube mounting tube end cover 41; the water pump 7 is arranged on the Piston tube installation tube 4 outside. The piston tube 1 includes a steel piston tube body 14 and a wear-resistant sleeve 15 arranged on the radially inner peripheral surface of the piston tube body 14 . The lock nut 43 is screwed to the radially outer peripheral surface of the piston tube body 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com