High-temperature alloy tensile property sample and preparation method thereof

A high-temperature alloy and tensile performance technology, applied in the preparation of test samples, etc., can solve problems such as inability to complete the test process, breakage of the working section, etc., and achieve the effects of not easy sample deformation, stable arc, and good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

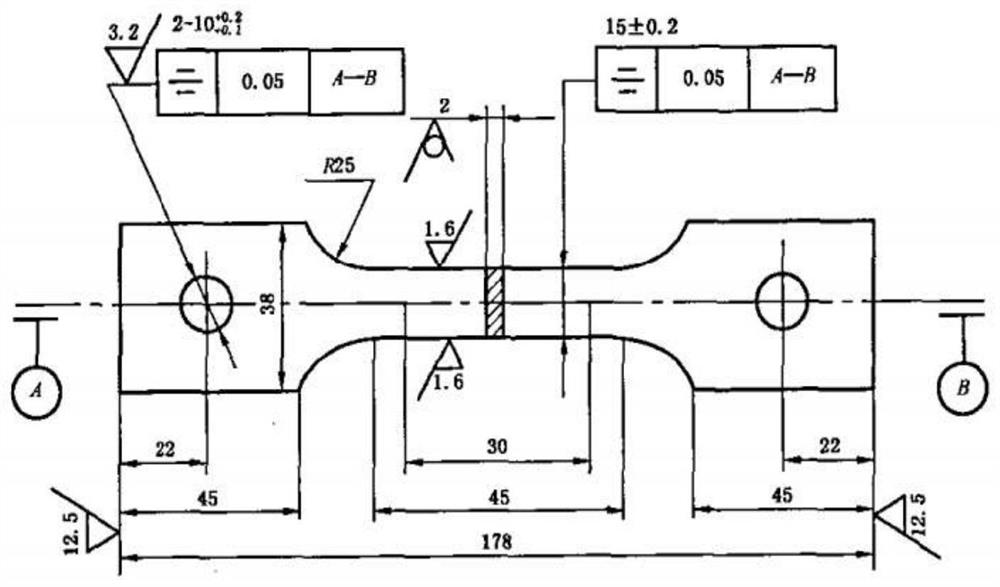

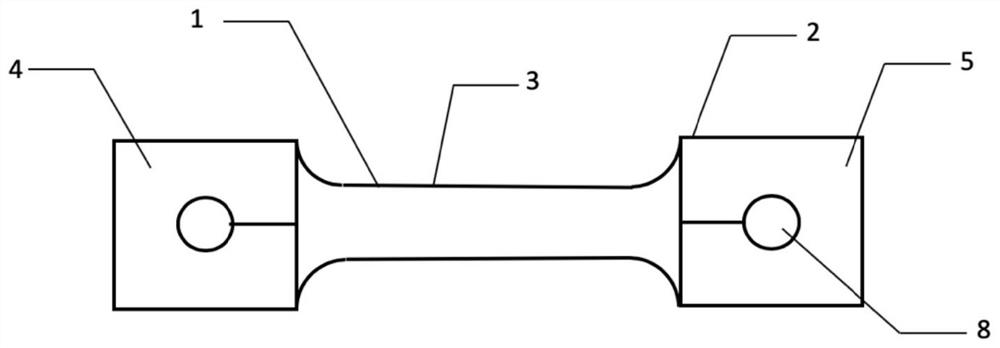

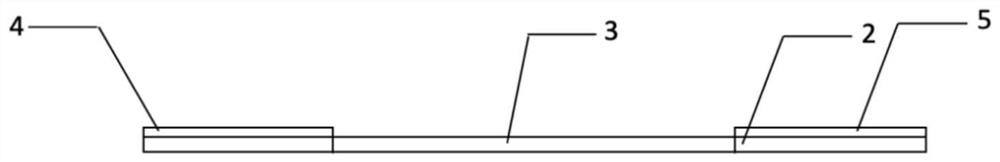

[0027] A high-temperature alloy tensile performance sample, including a high-temperature alloy sample to be tested 1, the two ends of the high-temperature alloy sample to be tested are clamping ends 2, and between the clamping ends is a working section 3. A patch one 4 and a patch two 5 are attached to the upper surface of the holding end respectively. The patch is a high-temperature alloy thin plate, the thickness of the patch is 0.8mm, the patch is connected to the high-temperature alloy sample to be tested by gas welding, and the solder joints are located in the middle of the four corners of the patch and the two sides of the patch, There is a positioning hole 8 in the center of the patch. The size of the positioning hole is the same as that of the clamping end. The size of the superalloy sample to be tested is selected from GB / T 228.2-2015. The sheet is also a cobalt-based superalloy.

Embodiment 2

[0029] A high-temperature alloy tensile performance sample, including a high-temperature alloy sample to be tested 1, the two ends of the high-temperature alloy sample to be tested are clamping ends 2, and between the clamping ends is a working section 3. A patch one 4 and a patch two 5 are attached to the upper and lower surfaces of the holding end respectively. The patch is a high-temperature alloy thin plate, the thickness of the patch is 0.5mm, the patch is connected to the high-temperature alloy sample to be tested by arc welding, and a positioning hole 8 is opened in the center of the patch, and the size of the positioning hole is The size of the positioning hole is the same as that of the clamping end. The size of the superalloy sample to be tested is selected from GB / T 228.2-2015. The superalloy to be tested and the patch are both iron-based superalloys.

Embodiment 3

[0031] A high-temperature alloy tensile performance sample, including a high-temperature alloy sample to be tested 1, the two ends of the high-temperature alloy sample to be tested are clamping ends 2, and between the clamping ends is a working section 3. The upper and lower surfaces of the holding end are respectively attached with patch one 4, patch two 5, patch three 6 and patch four 7. The patch is a high-temperature alloy thin plate, the thickness of the patch is 0.5mm, the patch is connected to the high-temperature alloy sample to be tested by vacuum diffusion welding, and a positioning hole 8 is opened in the center of the patch. The size is the same as the size of the positioning hole at the clamping end. The size of the superalloy sample to be tested is selected from GB / T 228.2-2015. The superalloy to be tested and the patch are both nickel-based superalloys.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com