High-entropy oxides for thermal barrier coating (TBC) top coats

A technology of thermal barrier coating and oxide, applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve the problems of increasing coating weight and density

Active Publication Date: 2021-05-25

오를리콘메트코유에스아이엔씨

View PDF17 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

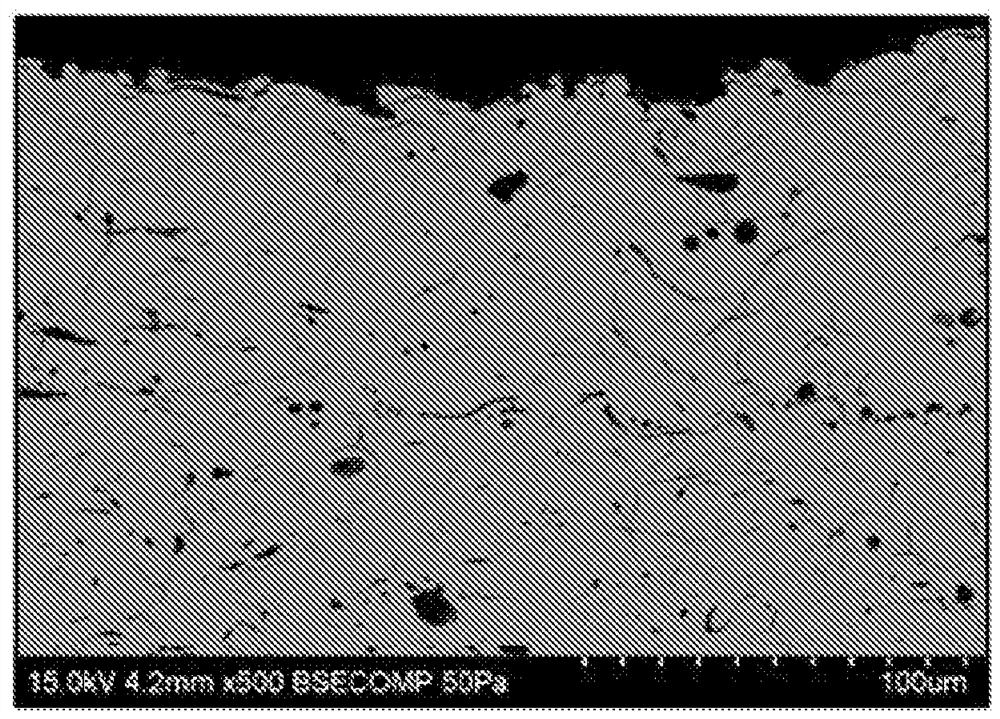

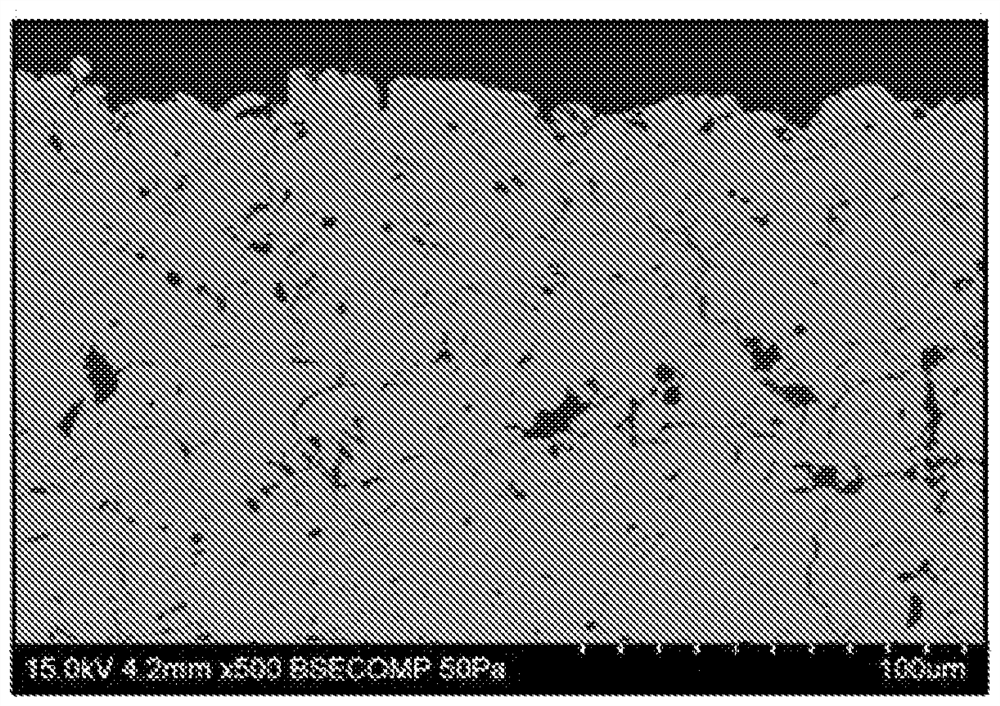

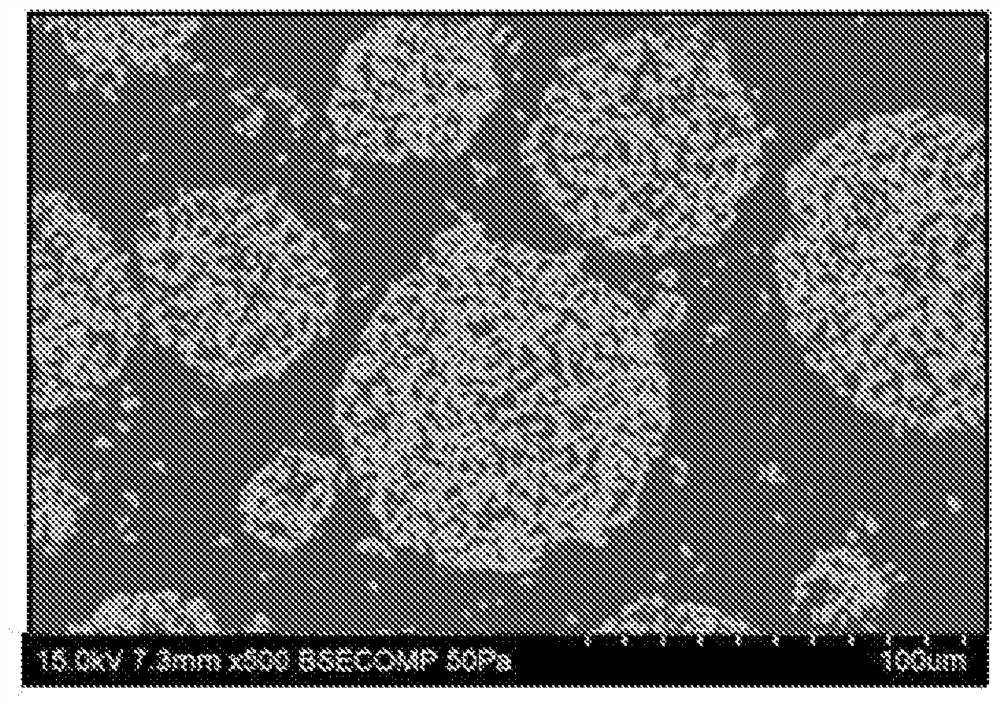

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0154] Table 1 shows the composition of four inventive HEO TBC topcoat materials (as powders) used to make inventive HEO TBC topcoats for coated substrates.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

A thermal barrier coating (TBC) top coat which is a high entropy oxide (HEO) having a high configurational entropy, contains at least 5 different oxide-forming metallic cations, is a single phase or single crystalline structure, such as tetragonal or cubic over unexpectedly wide temperature ranges up to and beyond top coat operating temperatures of preferably at least 2300 DEG F. The TBC top coats exhibit low thermal conductivity, good sintering resistance, excellent phase stability and good thermal cycling performance. At least five of the different oxide-forming metallic cations include: a) at least one of the transition metals: Sc, Y, Ti, Zr, V, Nb, Ta, Cr, Mo, W, Mn, Re, Fe, Ru, Co, Ni, Cu, or Zn, and / or at least one of the lanthanides La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb. Dy, Ho, Er, Yb, or Lu. One of the at least five different oxide-forming metallic cations may also comprise at least one of the alkaline-earth metals: Be, Mg, Ca, Sr, or Ba.

Description

[0001] Cross References to Related Applications [0002] This application claims the benefit of U.S. Provisional Patent Application No. 62 / 743,392, filed October 9, 2018, the disclosure of which is expressly incorporated herein by reference in its entirety. technical field [0003] The present invention relates to topcoat materials for thermal barrier coatings (TBC), which have excellent phase stability and dimensional stability over a wide temperature range, as well as good thermal cycle performance and low thermal conductivity. Topcoat materials can be in the form of powders, alloys, topcoats or coating layers, and can be applied in thermal spray powder form with bond coat materials to obtain thermal barrier coating (TBC) systems. The present invention also relates to a method for reducing delamination of a topcoat from a bond coat and a substrate, such as a gas turbine engine component. Background technique [0004] A complete thermal barrier coating system includes a to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/482C09D1/00

CPCC23C28/345C23C28/3455C23C28/32C23C28/321C23C28/3215C23C4/02C23C4/11C23C4/129C23C4/131C23C4/134C23C4/137C04B35/50C04B35/62222C04B35/488C04B35/49C04B35/486C04B2235/3208C04B2235/3206C04B2235/3213C04B2235/3205C04B2235/3215C04B2235/3224C04B2235/3229C04B2235/3227C04B2235/3225C04B2235/3232C04B2235/3244C04B2235/77C04B35/62695C04B35/64C04B2235/9669

Inventor J·何H·L·洛夫洛克N·周T·哈灵顿T·沙罗贝姆

Owner 오를리콘메트코유에스아이엔씨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com