Sandwich coated biscuit and preparation process thereof

A technology of sandwich coating and preparation process, applied in the field of biscuits, can solve the problems of low edible taste, easy separation, low adhesion and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A sandwich-coated biscuit, comprising two layers of biscuit bases and a sandwich layer arranged between the two layers of biscuit bases, the sandwich layer is mixed and cooled by filling materials coated on the inner sides of the two layers of biscuit bases After making, described sandwich material comprises the raw material of following weight portion:

[0045] 10 parts cocoa butter substitute

[0046] 3 parts Isomaltooligosaccharide

[0047] Flavor seasoning powder 5 parts.

[0048] Each part by weight of the flavor seasoning powder includes 2 parts by weight of cheese powder and 6 parts by weight of blueberry powder.

[0049] Each part by weight of the flavor seasoning powder includes 2 parts by weight of yellow cream and 6 parts by weight of matcha powder.

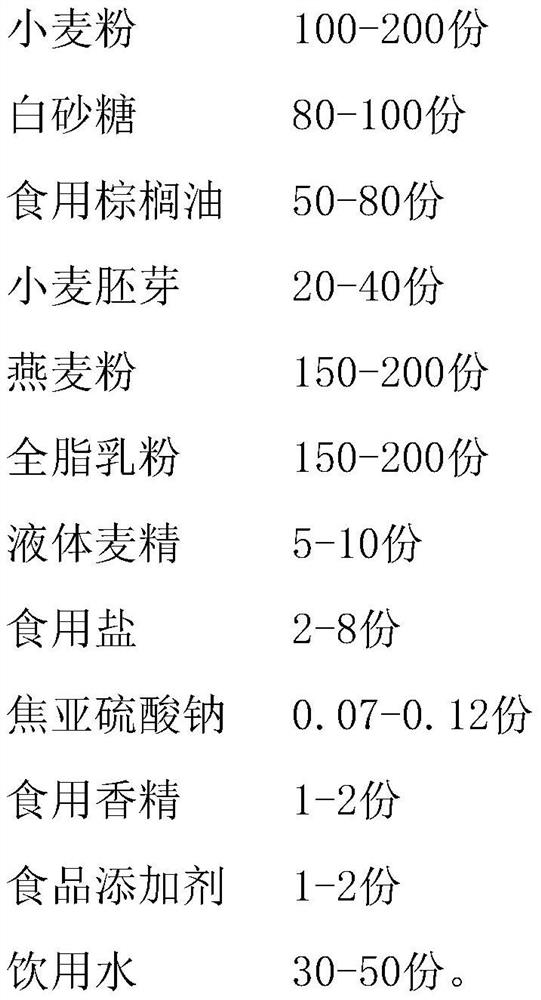

[0050] The biscuit base comprises the following raw materials in parts by weight:

[0051]

[0052]

[0053] The thickness of one layer of the biscuit base is 1.0 mm, and the thickness of the sandwich ...

Embodiment 2

[0059] A sandwich-coated biscuit, comprising two layers of biscuit bases and a sandwich layer arranged between the two layers of biscuit bases, the sandwich layer is mixed and cooled by filling materials coated on the inner sides of the two layers of biscuit bases After making, described sandwich material comprises the raw material of following weight portion:

[0060] 13 parts cocoa butter substitute

[0061] 4 parts Isomaltooligosaccharide

[0062] Flavor seasoning powder 6.5 parts.

[0063] Each part by weight of the flavor seasoning powder includes 2.5 parts by weight of cheese powder and 5.5 parts by weight of blueberry powder.

[0064] Each part by weight of the flavor seasoning powder includes 2.5 parts by weight of yellow cream and 5.5 parts by weight of matcha powder.

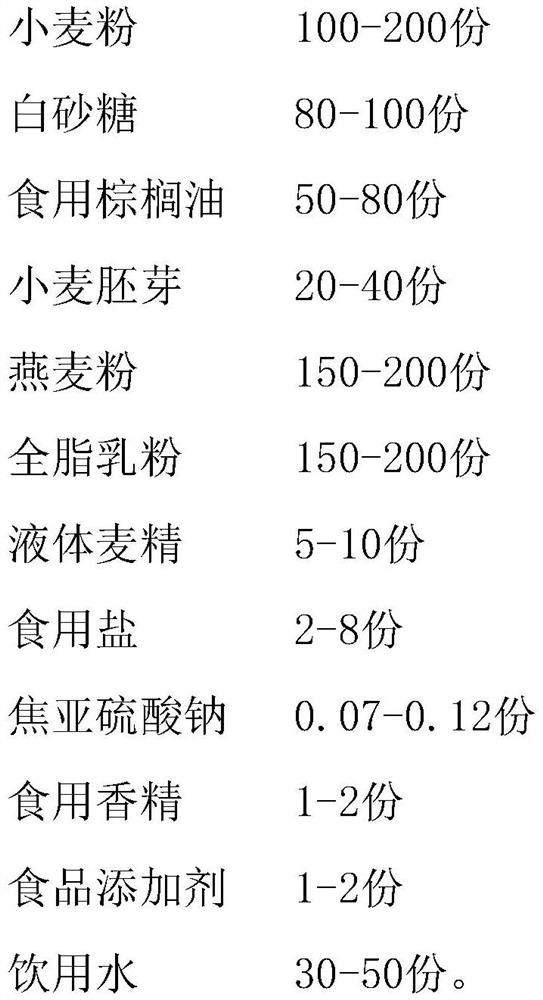

[0065] The biscuit base comprises the following raw materials in parts by weight:

[0066]

[0067] The thickness of one layer of the biscuit base is 1.2 mm, and the thickness of the sandwich la...

Embodiment 3

[0073] A sandwich-coated biscuit, comprising two layers of biscuit bases and a sandwich layer arranged between the two layers of biscuit bases, the sandwich layer is mixed and cooled by filling materials coated on the inner sides of the two layers of biscuit bases After making, described sandwich material comprises the raw material of following weight portion:

[0074] 15 parts cocoa butter substitute

[0075] Isomaltooligosaccharide 5 parts

[0076] Flavor seasoning powder 8 parts.

[0077] Each part by weight of the flavor seasoning powder includes 3 parts by weight of cheese powder and 5 parts by weight of blueberry powder.

[0078] Each part by weight of the flavor seasoning powder includes 3 parts by weight of yellow cream and 5 parts by weight of matcha powder.

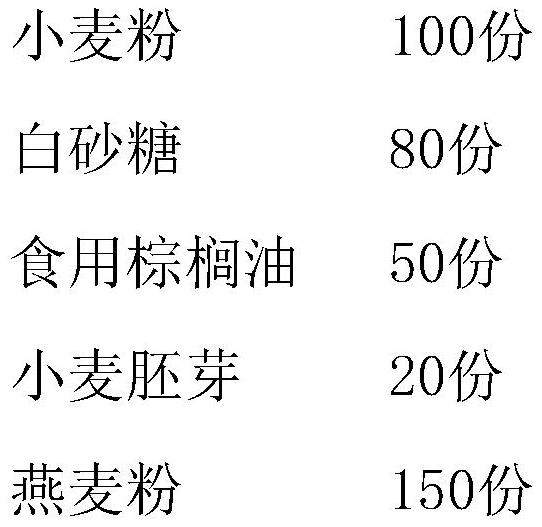

[0079] The biscuit base comprises the following raw materials in parts by weight:

[0080]

[0081]

[0082] The thickness of one layer of the biscuit base is 1.3 mm, and the thickness of the sandwich la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com