Fermented product prepared from auricularia auricula waste residues and fruit and vegetable wastes, composition of fermented product and application of fermented product to diabetes mellitus

A technology of fruit and vegetable waste and composition, applied in the direction of application, bacteria used in food preparation, food science, etc., can solve the problems of lack of in-depth exploration, achieve non-toxic and side effects, prevent and control diabetes, and have good safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

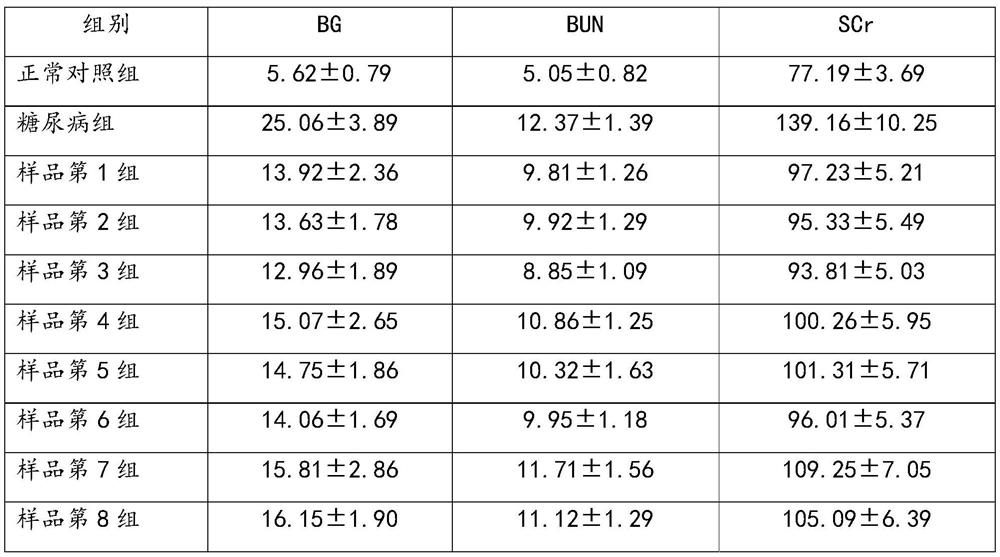

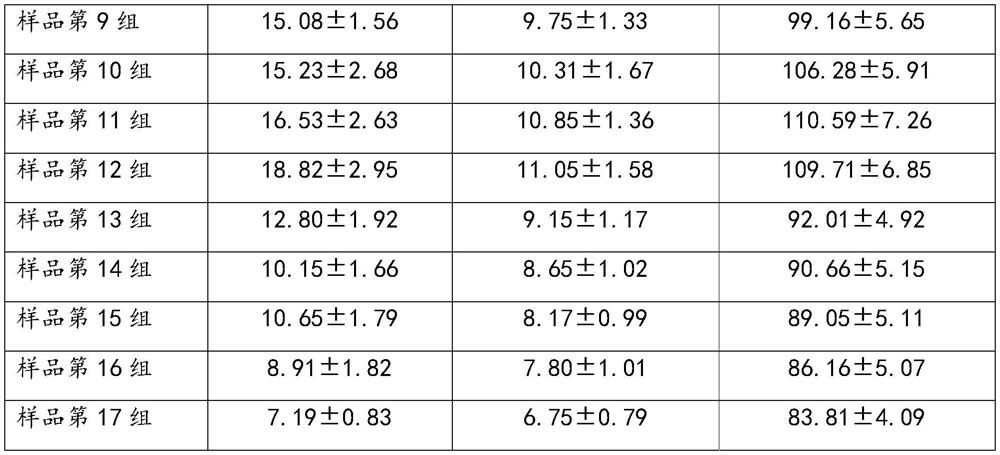

Examples

Embodiment 1

[0017] Extract the fungus under normal pressure at 90°C for 1 hour, add water to the filtered fungus residue according to the ratio of material to liquid 1:1, squeeze the juice, pass through a 100-mesh filter cloth, heat at 85°C for 12 minutes to kill enzymes and bacteria, and let cool. Add 3g of peptone and 0.2g of magnesium sulfate per liter of juice, inoculate with 0.1g of Lactobacillus plantarum powder, ferment at 37°C for 2 days, and freeze-dry to obtain a fungus fermented freeze-dried product.

Embodiment 2

[0019] Extract the fungus under normal pressure at 95°C for 1 hour, add water to the filtered fungus residue according to the ratio of material to liquid 1:2, squeeze the juice, pass through a 100-mesh filter cloth, heat at 80°C for 30 minutes to kill enzymes and bacteria, and let cool. Add 1 g of peptone and 0.3 g of magnesium sulfate per liter of juice, inoculate with 0.1 g of Lactobacillus plantarum powder, ferment at 25° C. for 6 days, and freeze-dry to obtain a fungus fermented freeze-dried product.

Embodiment 3

[0021] Extract the fungus under normal pressure at 92°C for 1 hour, add water to the filtered fungus residue according to the ratio of solid to liquid 1:1.5, squeeze the juice, pass through a 100-mesh filter cloth, heat at 83°C for 20 minutes to kill enzymes and bacteria, and let cool. Add 2g of peptone and 0.2g of magnesium sulfate per liter of juice, inoculate with 0.1g of Lactobacillus plantarum powder, ferment at 30°C for 4 days, and freeze-dry to obtain a fungus fermented freeze-dried product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com